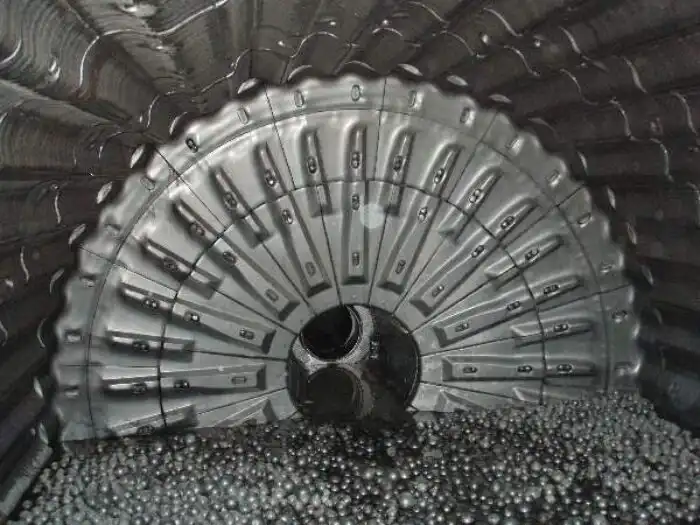

What grinding media is used in cement mill?

In cement mills, Ball Mill Grinding Media, typically steel balls or cylpebs, are essential for the grinding process. They come in various sizes, ranging from 20mm to 150mm in diameter. The choice of media depends on factors like cement type, mill size, and desired product fineness. High-quality grinding media is vital for efficient cement production, as it affects mill performance, energy consumption, and cement quality. Steel balls are preferred for their durability, impact resistance, and effectiveness in reducing particle size, ensuring optimal efficiency and consistent cement quality.

Cylpebs Grinding Media: Properties, Applications, and Performance

.webp)

In the realm of industrial grinding processes, cylpebs grinding media has emerged as a potent alternative to traditional ball media. These cylindrical-shaped grinding bodies offer distinct advantages in specific grinding operations, particularly in achieving higher grinding efficiency and improved particle size distribution. This article delves into the properties, applications, and performance of cylpebs, shedding light on their growing significance in various industries, such as mining, cement, and chemical processing.

What is the optimal specific gravity for grinding balls?

The specific gravity of grinding balls for mining is an important factor in influencing the efficacy and efficiency of grinding operations in the mineral processing industry. Knowing the ideal specific gravity of your grinding medium is crucial if you work in a field that uses ball mills, such as mining or cement manufacture. Learn how to find the sweet spot for your grinding balls by reading this article's breakdown of the variables that affect specific gravity.

What are the specifications for laboratory-scale grinding media?

Laboratory-scale grinding media play a crucial role in various scientific and industrial applications, particularly in material processing and research. Understanding the specifications for these specialized tools is essential for achieving precise and reliable results in experimental settings. This comprehensive guide delves into the key parameters, size and material options, and optimization strategies for laboratory-scale ball mill grinding media.

How does grinding media bulk density influence mill filling degree?

Improving efficiency and performance in industrial grinding requires a deep grasp of the complex interaction between mill filling degree, ball mill grinding media bulk density, and other related factors. The significance of this link and its effects on numerous sectors are understood by NINGHU, a prominent grinding media manufacturer. The intricacies of bulk density, how it affects mill filling, and methods for optimising grinding efficiency are all covered in this detailed tutorial.

How does high chrome content affect grinding ball performance?

When it comes to industrial grinding, the make-up of the grinding media is very important for how well it works and how long it lasts. In recent years, high chrome grinding balls have become very popular because they work better than other types. This piece goes into detail about how the amount of chrome in grinding balls affects their performance. It also talks about the benefits, uses, and common myths about these important parts of the grinding process.

How do high chrome grinding balls compare to steel grinding balls?

When it comes to mineral handling and making cement, grinding media is very important for getting the best results and efficiency. High chrome grinding balls and steel balls are two famous types of grinding balls. This complete guide will explain the differences between these two types so that you can make an intelligent choice for your grinding needs.

What is the cost-effectiveness of high chrome grinding balls?

In industrial grinding processes, the type of grinding media used can have a big effect on both how well the process works and how much it costs generally. Due to their durability and performance, high chrome grinding balls are becoming more famous in many fields. But do they really save money? This in-depth study will look at the costs and benefits of using high chrome grinding balls, including how long they last, how they affect production costs, and how to get the most out of them.

What is the metallurgical composition of high chrome grinding balls?

High-chrome grinding balls are important parts of many businesses, such as mining, making cement, and making electricity. Their unique mechanical makeup is a key part of how well they work and how long they last. We will talk about the complex makeup of high chrome grinding balls, contrast it with other metals, and look at how it impacts the efficiency of grinding in this in-depth guide.

How does grinding media material influence grinding product purity standards?

When it comes to industrial grinding, the material used for the grinding media, including ball mill grinding media, is very important to how pure the finished product is. This blog post goes into detail about the complicated connection between grinding media materials and standards for product purity. It contains useful information for fields that depend on precise grinding processes.

How does grinding media impact wear resistance?

Grinding media is very important in many industrial processes, especially in the mining and cement businesses. Wear resistance is one of the most important things about grinding media because it has a direct effect on how well it works, how much it costs, and the quality of the result. This complete guide will look into the complicated connection between grinding media and wear resistance, explaining how it works, what it's used for, and some common misunderstandings.

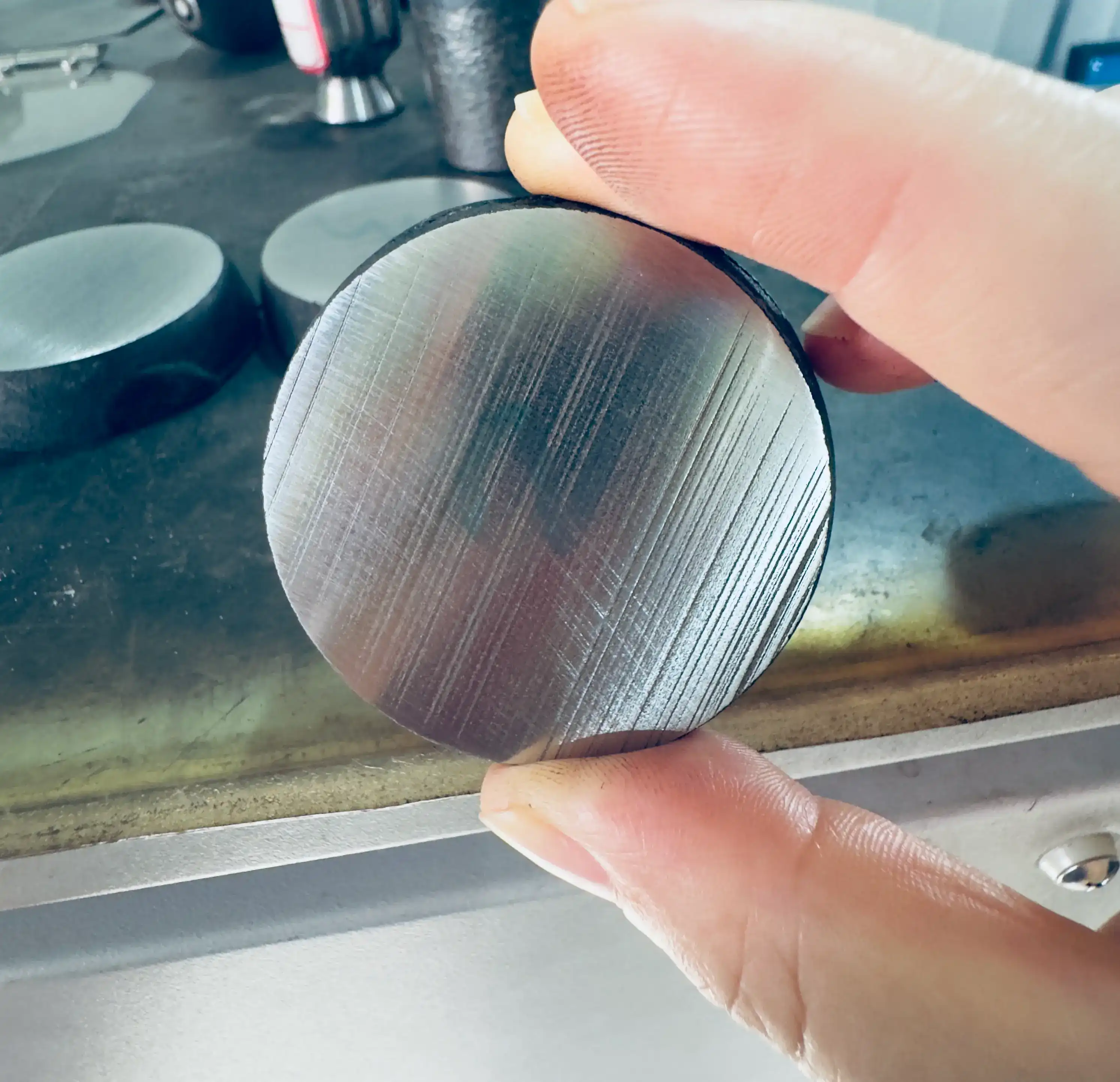

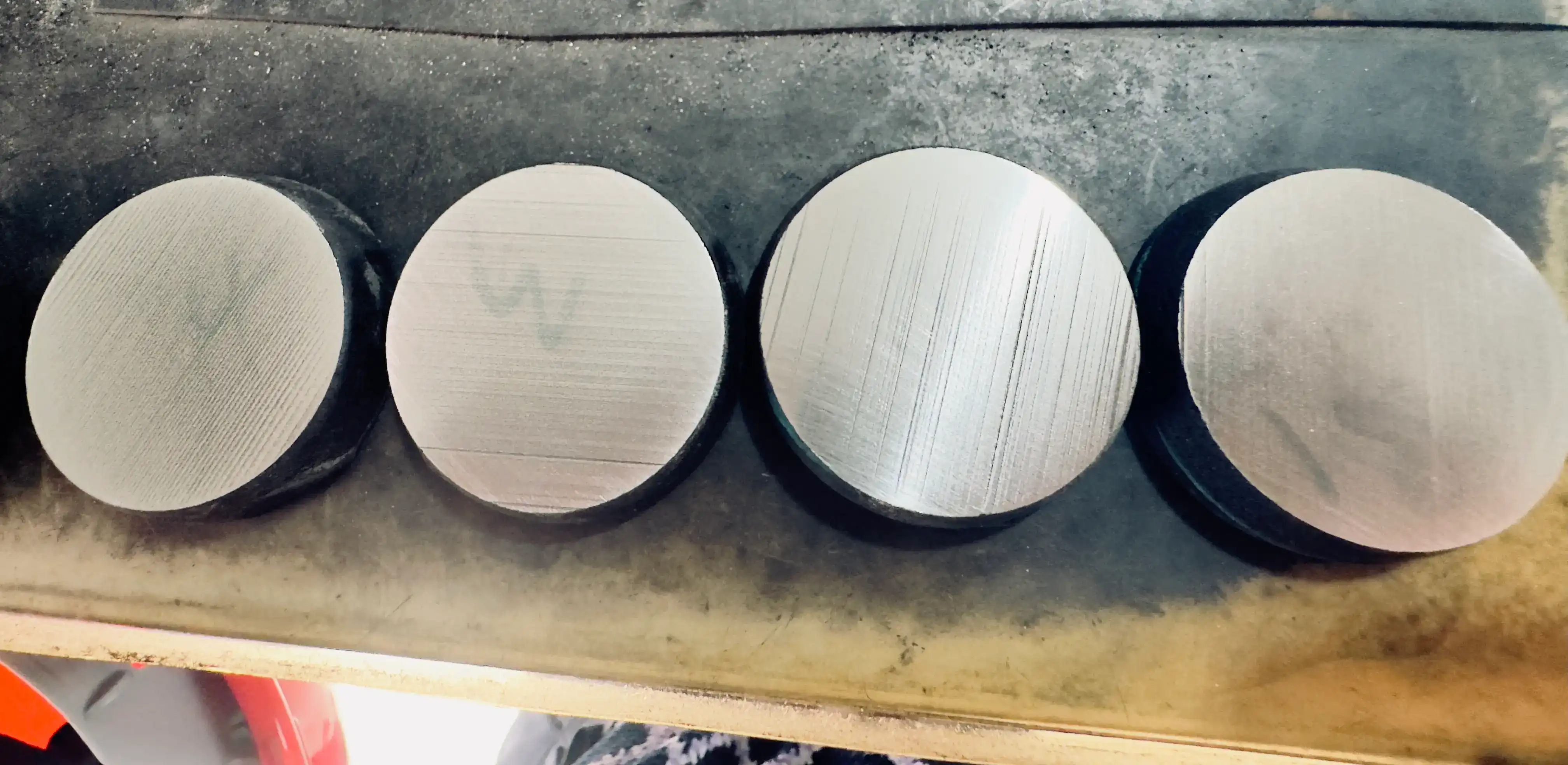

Importing Chrome Grinding Balls: What to Check

.webp)

When importing chrome grinding balls for industrial applications, you should know what makes a good one. Consider the power, chromium makeup, and manufacturing process of a high chrome grinding ball before choosing it. Looking over chemical makeup certificates, making sure measurements are correct, and looking over wear resistance standards are all important steps. Procurement teams need to check on the skills, output capabilities, and quality control systems of their sources to make sure they can do the same work in mining, cement, and industry uses.