Understanding the relationship between density and filling

The bulk density of grinding media plays a significant role in determining the optimal filling degree of a mill. This relationship is fundamental to achieving the desired grinding results while maintaining operational efficiency.

Defining bulk density and its significance

Bulk density refers to the mass of grinding media per unit volume, including the voids between individual balls or cylpebs. It's a critical factor in ball mill grinding media selection, as it directly affects the mill's capacity and grinding efficiency.

How bulk density affects mill filling

Higher bulk density grinding media occupies less volume for the same weight, allowing for a greater mass of media within the mill. This increased mass can lead to more efficient grinding, but it also requires careful consideration of the optimal filling degree to prevent overloading and maintain proper tumbling action.

Optimizing mill performance through proper filling

Achieving the right balance between grinding media bulk density and mill filling degree is essential for maximizing grinding efficiency and minimizing operational costs.

The importance of proper mill filling

Correct mill filling ensures optimal grinding performance by providing sufficient media for effective particle size reduction while maintaining adequate space for material movement and impact. Overfilling or underfilling can lead to reduced efficiency, increased wear, and higher energy consumption.

Factors influencing optimal filling degree

Several factors affect the ideal filling degree for a given mill and grinding media combination:

- Mill size and design

- Grinding media size and shape

- Material characteristics

- Desired product fineness

- Operational parameters (e.g., mill speed, feed rate)

Calculating ideal media density for maximum efficiency

Determining the optimal grinding media bulk density and corresponding mill filling degree requires careful analysis and calculation.

Methods for determining ideal media density

To calculate the ideal media density for a specific application, consider the following approaches:

- Empirical testing: Conduct trials with various media densities and filling degrees to identify the optimal combination for your specific grinding requirements.

- Mathematical modeling: Utilize advanced simulation tools to predict grinding performance based on media properties and mill parameters.

- Industry benchmarks: Refer to established guidelines for similar applications and adjust based on your unique operational conditions.

Balancing density and filling for optimal performance

Finding the right balance between grinding media bulk density and mill filling degree is crucial for achieving maximum grinding efficiency. Higher density media may allow for increased grinding power, but it also requires careful adjustment of the filling degree to maintain proper media motion and prevent overloading.

We have a variety of ball mill grinding media applications available at NINGHU, with densities to fit different industrial demands. Whatever your grinding needs may be, our professional staff can help you choose the best media and calculate the correct filling degree.

Practical considerations for implementing density-based filling strategies

When applying density-based filling strategies in your grinding operations, keep the following practical considerations in mind:

Monitoring and adjusting fill levels

Regularly monitor mill performance and adjust fill levels as needed to maintain optimal grinding efficiency. Factors such as media wear and changes in material characteristics may necessitate periodic adjustments to the filling degree.

Adapting to changing operational conditions

Be prepared to modify your grinding media and filling strategy in response to changes in operational conditions, such as variations in feed material or production requirements. Flexibility in your approach will help ensure consistent grinding performance across diverse scenarios.

The impact of grinding media properties on mill efficiency

While bulk density is a crucial factor, other grinding media properties also play a significant role in determining mill efficiency and optimal filling degree.

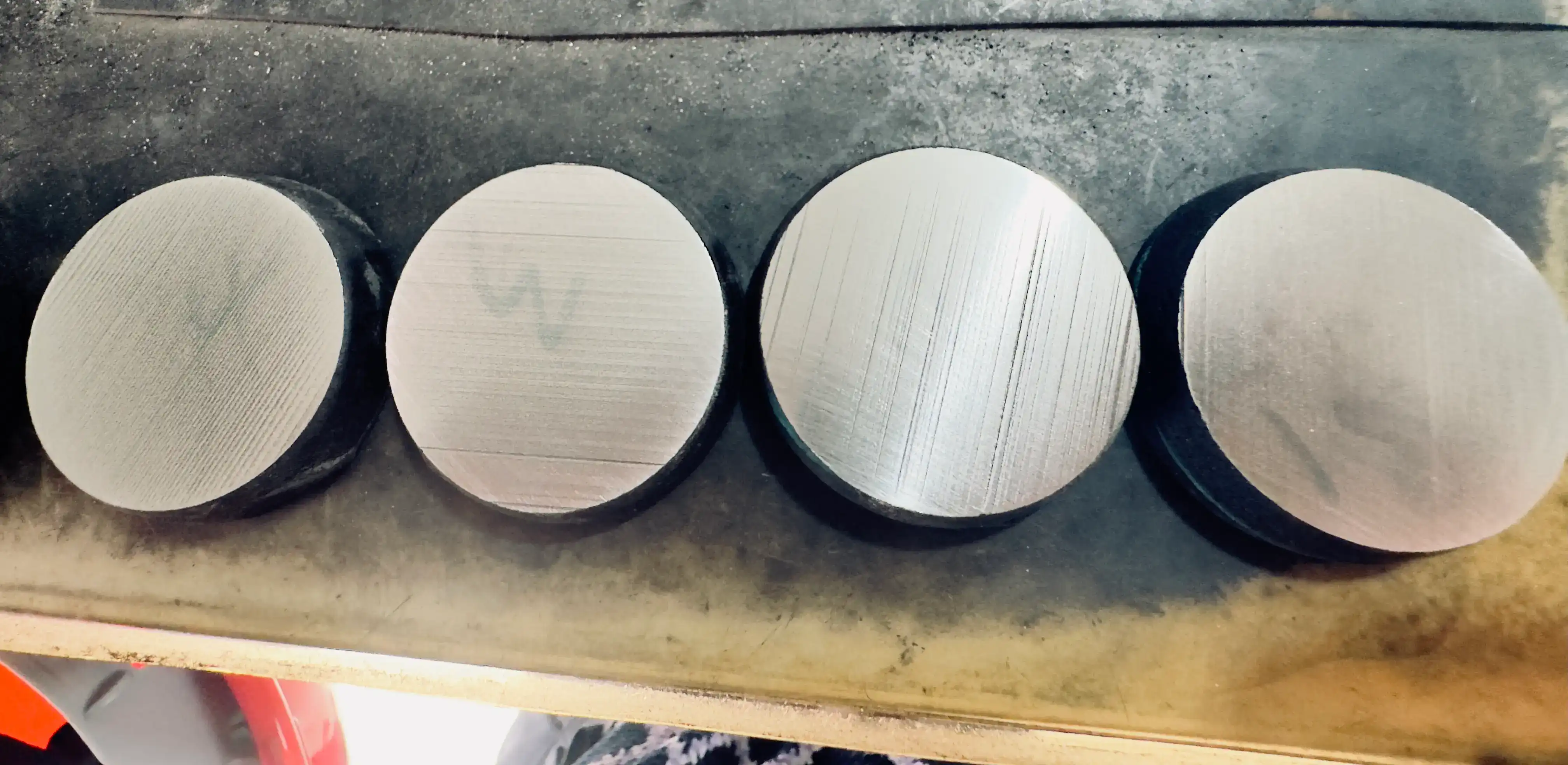

Size and shape considerations

The size and shape of grinding media influence their packing density and motion within the mill. Spherical grinding balls for ball mill applications may have different filling requirements compared to cylindrical media or irregular shapes. Consider these factors when determining the ideal filling degree for your specific media type.

Material composition and wear resistance

The material composition of grinding media affects not only its density but also its wear resistance and grinding efficiency. High-chrome grinding media, for example, may offer increased durability and allow for higher filling degrees due to their extended lifespan.

Optimizing energy efficiency through proper media selection and filling

Selecting the right grinding media and filling degree can significantly impact the energy efficiency of your milling operation.

Energy consumption considerations

Higher density media may require more energy to lift and tumble within the mill, but they can also provide more efficient grinding. Balancing these factors is crucial for optimizing overall energy efficiency.

Strategies for reducing power consumption

Implement the following strategies to minimize power consumption while maintaining grinding efficiency:

- Optimize media size distribution

- Fine-tune mill speed and filling degree

- Implement advanced control systems for real-time adjustment

- Consider using high-performance grinding aids

Case studies: Real-world applications of density-based filling optimization

Examining real-world examples can provide valuable insights into the practical benefits of optimizing grinding media bulk density and mill filling degree.

Cement industry application

A cement plant implemented a new filling strategy using high-density grinding media, resulting in a 15% increase in throughput and a 10% reduction in specific energy consumption.

Mining sector success story

A gold mining operation optimized its ball mill grinding media density and filling degree, leading to a 20% improvement in grind fineness and a 12% reduction in media consumption.

Future trends in grinding media and mill optimization

As technology continues to advance, new opportunities for improving grinding efficiency through media and mill optimization are emerging.

Advancements in grinding media materials

Research into novel materials and composites promises to deliver grinding media with enhanced properties, potentially revolutionizing density-based filling strategies.

Intelligent mill control systems

The integration of artificial intelligence and machine learning in mill control systems may enable real-time optimization of filling degrees based on changing operational conditions.

Conclusion

Understanding the relationship between grinding media bulk density and mill filling degree is essential for optimizing grinding performance across various industries. By carefully considering factors such as media properties, mill design, and operational parameters, you can achieve significant improvements in efficiency, product quality, and energy consumption.

At NINGHU, we are committed to helping our customers achieve optimal grinding performance through expert guidance and high-quality grinding media solutions. Our team of specialists can assist you in selecting the ideal grinding media and determining the optimal filling degree for your specific application.

Ready to optimize your grinding process?

In order to maximise the efficiency and productivity of your mill, contact NINGHU today to learn more about our expert consulting services and our comprehensive range of ball mill grinding media solutions. Reach out to us at sales@da-yang.com or sunny@da-yang.com to get started on your path to improved grinding performance.