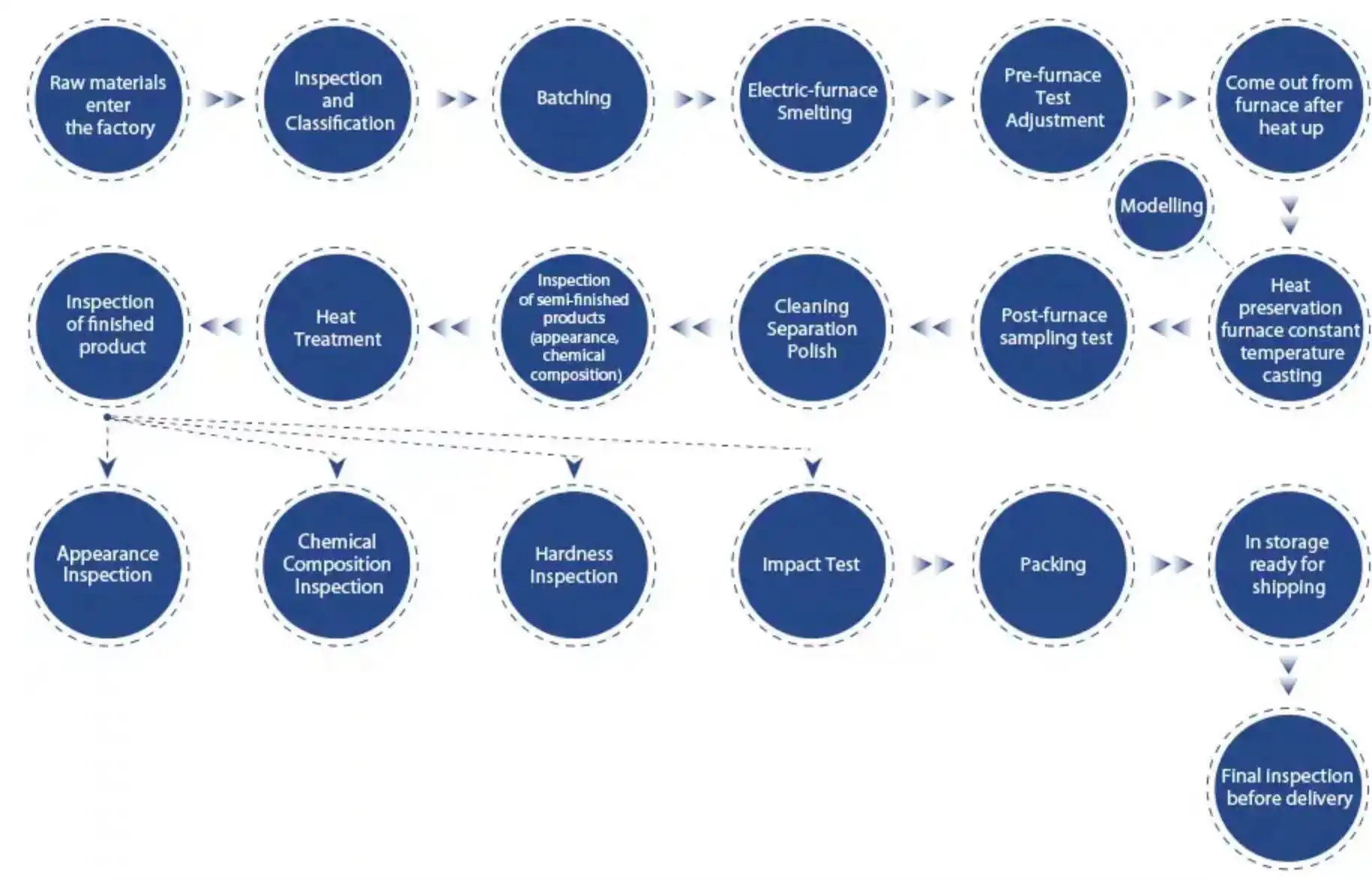

Quality Control Measures: Discussing quality control standards and procedures implemented during the manufacturing process to ensure the consistency and reliability of low chrome grinding cylpebs.

Quality control measures play a pivotal role in ensuring the consistency and reliability of manufactured products. In the realm of manufacturing, particularly in industries dealing with products like low chrome grinding cylpebs, adhering to stringent quality control standards is imperative to maintain customer satisfaction, enhance competitiveness, and uphold brand reputation. This article delves into the various quality control measures employed in the manufacturing process, focusing on the standards, procedures, and technologies utilized to ensure product quality and consistency.

Are Cylpebs Grinding Media Cost-Effective?

Grinding Cylpebs play a critical role in the grinding and comminution processes within industries like mining, cement, and power generation. Cylpebs, a type of grinding media, have been increasingly favored due to their distinct shape and composition. However, assessing the cost-effectiveness of cylpebs as grinding media requires thorough exploration.

How Can Grinding Balls Minimize Contamination in Grinding Processes?

Tainting control is a basic worry in grinding processes across ventures, for example, drugs, food handling, and high level materials fabricating. Fired grinding balls assume a significant part in limiting defilement because of their novel properties and configuration highlights custom-made for spotless and exact grinding tasks.

How Are Grinding Balls Made?

The mining, concrete, and development enterprises, specifically, depend vigorously on Grinding Ball as fundamental parts. These balls are fundamental for delivering the unrefined substances utilized in assembling processes since they are utilized in crushing plants to smash and crush materials into better particles. Several intricate steps are involved in the production of grinding balls to ensure that they meet the stringent requirements for hardness and durability, from selecting the raw materials to the final heat treatment. This article digs into the entrancing assembling interaction of crushing balls and resolves a few habitually posed inquiries about their creation and application.

What is the cost comparison between different types of grinding balls?

What industries typically use casting grinding balls?

Casting grinding balls play a crucial role in various industrial processes, serving as indispensable tools for material reduction and refinement. These robust spheres, typically crafted from high-chrome or low-chrome alloys, have become staples in numerous sectors due to their durability and efficiency. In this comprehensive exploration, we'll delve into the diverse industries that rely on the product, examining their applications and benefits across different fields.

The Impact of Chromium Casting Grinding Balls on Product Quality and Cost Efficiency

.webp)

In the realm of industrial grinding processes, the choice of grinding media plays a pivotal role in determining both product quality and operational efficiency. Among the various options available, chromium casting grinding balls have emerged as a game-changer, offering a unique blend of durability, performance, and cost-effectiveness. This article delves into the multifaceted impact of these specialized grinding balls on product quality and cost efficiency across diverse industries.

What are the environmental considerations when using high chrome grinding media?

In the world of industrial grinding processes, high chrome grinding media has become increasingly popular due to its durability and efficiency. However, as environmental concerns continue to rise, it's crucial to examine the ecological impact of these materials. This article delves into the environmental considerations surrounding the use of high chrome grinding media, exploring both challenges and potential solutions.

How do grinding balls compare to other grinding media types?

Grinding balls, commonly used in mining, offer key advantages over other grinding media types. They are efficient, durable, and versatile, making them ideal for industrial use. Designed to endure the harsh conditions of ore processing, these balls provide consistent performance and long lifespan. Unlike rod mills or autogenous grinding, ball mills with high-quality grinding balls achieve finer particle sizes with lower energy consumption. Their spherical shape ensures optimal material contact, leading to uniform particle distribution. Grinding Balls for Mining can also be customized in size and composition, offering flexibility for diverse mineral processing needs.

Optimizing Performance with Steel Balls for Ball Mills

In the world of mineral processing and materials handling, ball mills play a crucial role in grinding and refining raw materials. At the heart of these powerful machines are the unsung heroes: steel balls for ball mills. These small but mighty components are essential for achieving optimal grinding performance and efficiency. In this comprehensive guide, we'll explore how to maximize the effectiveness of your ball mill operations using high-quality steel balls.

Maximize Ball Mill Performance with the Right Grinding Media

In the world of industrial processing, ball mills play a crucial role in reducing particle size and refining materials. However, the success of these operations hinges on a often-overlooked component: grinding media. Selecting the appropriate grinding media in ball mill can significantly enhance your ball mill's performance, leading to improved efficiency, reduced costs, and superior end products. This article delves into the intricacies of grinding media, exploring their impact on particle size reduction, factors affecting their longevity, and cost-effective solutions for optimizing your ball mill operations.

How does media perform in high-frequency vibratory mills?

The effectiveness and adaptability of high-frequency vibratory mills have led to their rising popularity across a range of sectors. In comparison to more traditional milling techniques, these mills have some distinct benefits because to the fast vibrations they use to grind and treat materials. Nevertheless, there are advantages and disadvantages to the ball mill media's performance in these high-frequency settings. Choosing the right media for high-frequency vibratory mills and traditional mills is an important topic, and this article will go into the complexities of media performance in both types of mills.