Impact of media density on kinetic energy transfer

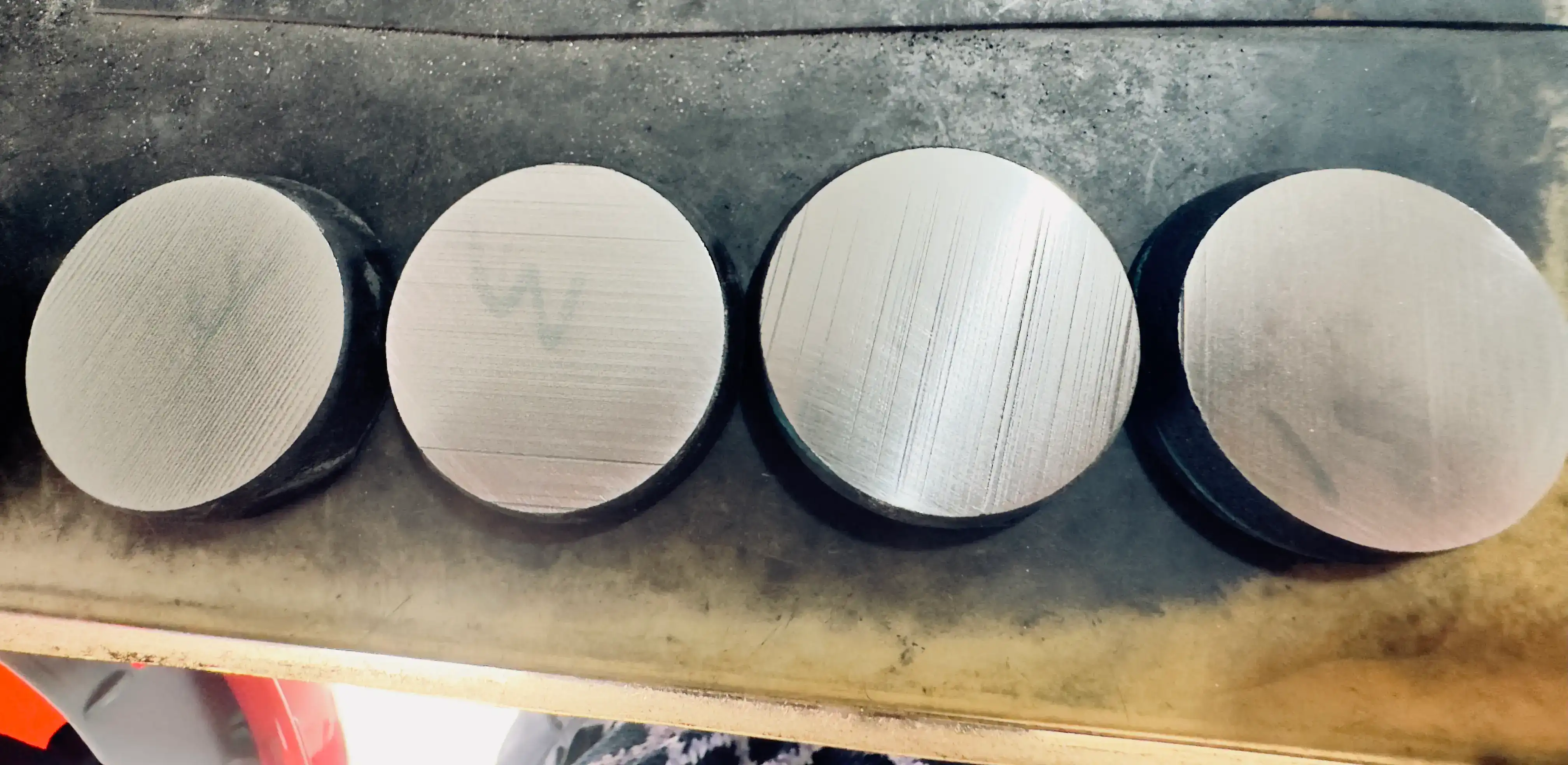

The density of grinding media plays a pivotal role in the transfer of kinetic energy during the grinding process. When we talk about media density, we're referring to the mass per unit volume of the grinding balls or cylpebs used in a ball mill media. This characteristic directly affects how energy is transferred from the mill to the material being ground.

Understanding kinetic energy in ball mills

In a ball mill, the grinding media cascades and tumbles as the mill rotates, creating impacts and shear forces that break down the material. The kinetic energy of these impacts is a function of the mass and velocity of the grinding media. Higher density media, such as steel balls, possess more mass and thus carry more kinetic energy at the same velocity compared to lower density media like ceramic balls.

Density-dependent energy transfer efficiency

The efficiency of energy transfer from the grinding media to the material being ground is closely tied to media density. Denser media can impart more energy upon impact, potentially leading to more effective particle size reduction. This is particularly beneficial when dealing with hard or coarse materials that require significant force to break down.

However, it's important to note that higher density doesn't always equate to better efficiency. The optimal media density depends on various factors, including the hardness and brittleness of the material being ground, the desired particle size, and the specific energy requirements of the grinding process.

High-density vs low-density media: Energy consumption comparison

When comparing high-density and low-density ball mill media, energy consumption is a critical factor to consider. The choice between these options can significantly impact the overall efficiency and cost-effectiveness of your grinding operation.

Energy efficiency of high-density media

High-density grinding media, such as steel grinding balls, are often favored in applications requiring high impact energy. These media types can be particularly efficient in terms of energy utilization when grinding hard or coarse materials. The higher mass of steel balls allows them to maintain momentum better, potentially reducing the energy input required from the mill drive.

However, the use of high-density media also comes with some energy-related drawbacks. The increased weight of the media charge means that more energy is required to lift and rotate the mill. This can lead to higher power consumption, especially in larger mills or those operating at higher speeds.

Energy profile of low-density media

Low-density grinding media, like ceramic balls, present a different energy consumption profile. While they may not deliver the same impact energy as their high-density counterparts, they offer advantages in terms of overall energy efficiency.

The lighter weight of low-density media reduces the power required to rotate the mill. This can lead to significant energy savings, particularly in continuous operation scenarios. Additionally, low-density media often excel in fine grinding applications, where the emphasis is more on attrition and shear forces rather than high-impact collisions.

Balancing density and energy consumption

The key to optimizing energy consumption lies in finding the right balance between media density and grinding requirements. In some cases, a mix of high and low-density media can provide the best of both worlds, combining the high-impact efficiency of dense media with the energy-saving benefits of lighter options.

At NINGHU, we offer a range of grinding media options to help you find the perfect balance for your specific application. Our team can assist in selecting the ideal media density to maximize grinding efficiency while minimizing energy consumption.

How to calculate grinding efficiency based on media density?

Calculating grinding efficiency with respect to ball mill media density involves considering several factors and using specific formulas. This process helps in optimizing the grinding operation and selecting the most appropriate media for a given application.

Key factors in grinding efficiency calculations

Before delving into the calculation methods, it's important to understand the key factors that influence grinding efficiency:

- Media density (ρ)

- Mill rotational speed (ω)

- Mill diameter (D)

- Media size distribution

- Material characteristics (hardness, brittleness, etc.)

- Desired product fineness

Efficiency calculation methods

While there's no single, universal formula for calculating grinding efficiency based on media density, several approaches can provide valuable insights:

1. Bond Work Index Method

The Bond Work Index (Wi) is a measure of the resistance of material to crushing and grinding. It can be used to estimate the energy required for size reduction. The formula is:

E = 10 Wi (1/√P - 1/√F)

Where: E = Energy consumed per ton of feed Wi = Work index P = Product particle size (80% passing) F = Feed particle size (80% passing)

While this method doesn't directly account for media density, it can be used in conjunction with media density data to compare the efficiency of different media types.

2. Specific Energy Consumption

Specific energy consumption (SEC) is a useful metric for comparing grinding efficiency across different media densities. It's calculated as:

SEC = Energy Input / Mass of Product

By comparing the SEC values for different media densities, you can assess which option provides the most efficient grinding process.

3. Mill Power Draw Calculation

The power draw of a ball mill is influenced by media density. A simplified formula for mill power draw is:

P = 0.285 × D2.5 × L × N × (1 - 0.937J) × ρa

Where: P = Power draw (kW) D = Mill diameter (m) L = Mill length (m) N = Mill speed (rpm) J = Fraction of critical speed ρa = Apparent density of charge (t/m³)

This formula demonstrates how media density (reflected in the apparent density of charge) directly affects power consumption and, consequently, grinding efficiency.

Practical application of efficiency calculations

To apply these calculations in practice:

- Conduct controlled grinding tests with different media densities

- Measure energy consumption and product characteristics for each test

- Calculate efficiency metrics using the methods described above

- Compare results to determine the most efficient media density for your specific application

Remember, theoretical calculations should always be validated with practical testing. At NINGHU, we can assist you in conducting these tests and interpreting the results to optimize your grinding process.

Conclusion

Understanding the influence of ball mill media density on grinding efficiency is crucial for optimizing industrial grinding processes. From the impact on kinetic energy transfer to energy consumption comparisons and efficiency calculations, media density plays a multifaceted role in determining the overall performance of a ball mill.

At NINGHU, we leverage our extensive experience in wear-resistant materials production to provide high-quality grinding media solutions tailored to your specific needs. Whether you require high chrome casting grinding balls for high-impact applications or lower density options for energy-efficient fine grinding, our team is here to help you make the best choice for your grinding operations.

By carefully considering media density in relation to your specific grinding requirements, you can significantly enhance the efficiency of your processes, reduce energy consumption, and ultimately improve your bottom line.

Ready to optimize your grinding efficiency with the right media density? Contact our expert team at NINGHU today. We're here to provide personalized solutions and help you achieve peak performance in your grinding operations. Reach out to us at sales@da-yang.com or sunny@da-yang.com to discuss your grinding media needs and discover how we can enhance your industrial processes.

References

- Johnson, R. A., & Smith, K. L. (2019). Advanced Grinding Technologies: Media Density Effects on Mill Performance.

- Zhang, Y., & Wang, H. (2020). Computational Modeling of Media Density Influence in Ball Milling Processes.

- Garcia, M., & Rodriguez, F. (2018). Energy Efficiency in Mineral Processing: The Role of Grinding Media Selection.

- Thompson, E. J., & Brown, L. M. (2021). Optimizing Ball Mill Operations: A Comprehensive Guide to Media Density Considerations.

- Lee, S. H., & Patel, R. K. (2017). Innovative Approaches to Grinding Efficiency Calculations in Modern Mineral Processing.

- Anderson, T. C., & Wilson, D. R. (2022). The Future of Industrial Grinding: Advancements in Media Technology and Efficiency Metrics.