Sustainable Materials for Grinding Ball Production

Grinding balls are essential components in various industries, particularly in the mining and cement sectors, where they are used to pulverize ores and materials. However, the traditional production methods for grinding balls often involve the use of non-renewable resources and generate significant environmental impacts. In response to growing concerns about sustainability, manufacturers are increasingly exploring alternative materials and production processes. In this article, we delve into the concept of sustainable grinding ball production, examining the materials, methods, and implications for the industry.

How Do Grinding Balls Work?

In a variety of mills, Grinding Ball are an essential component for pulverizing and reducing solid materials into fine powder. These balls are essential to the mining, cement, and other industries that require materials to be reduced in size for further processing or production. They can be used in ball mills, sag mills, or autogenous grinding (AG) mills.

Can you use grinding balls in a SAG mill?

Grinding balls are essential components in the operation of SAG (Semi-Autogenous Grinding) mills, serving to crush ore and reduce it from large chunks into smaller pieces for further processing. SAG mills are primarily used at gold, copper, and platinum mines where they play a crucial role in the comminution of ores. Central to their operation are grinding balls, which are typically made of steel or other alloys and come in various sizes and compositions. These balls are loaded into the mill alongside the mined material to facilitate the grinding process. But can any grinding balls be used in a SAG mill? Let's delve into this question and explore the nuances of their application.

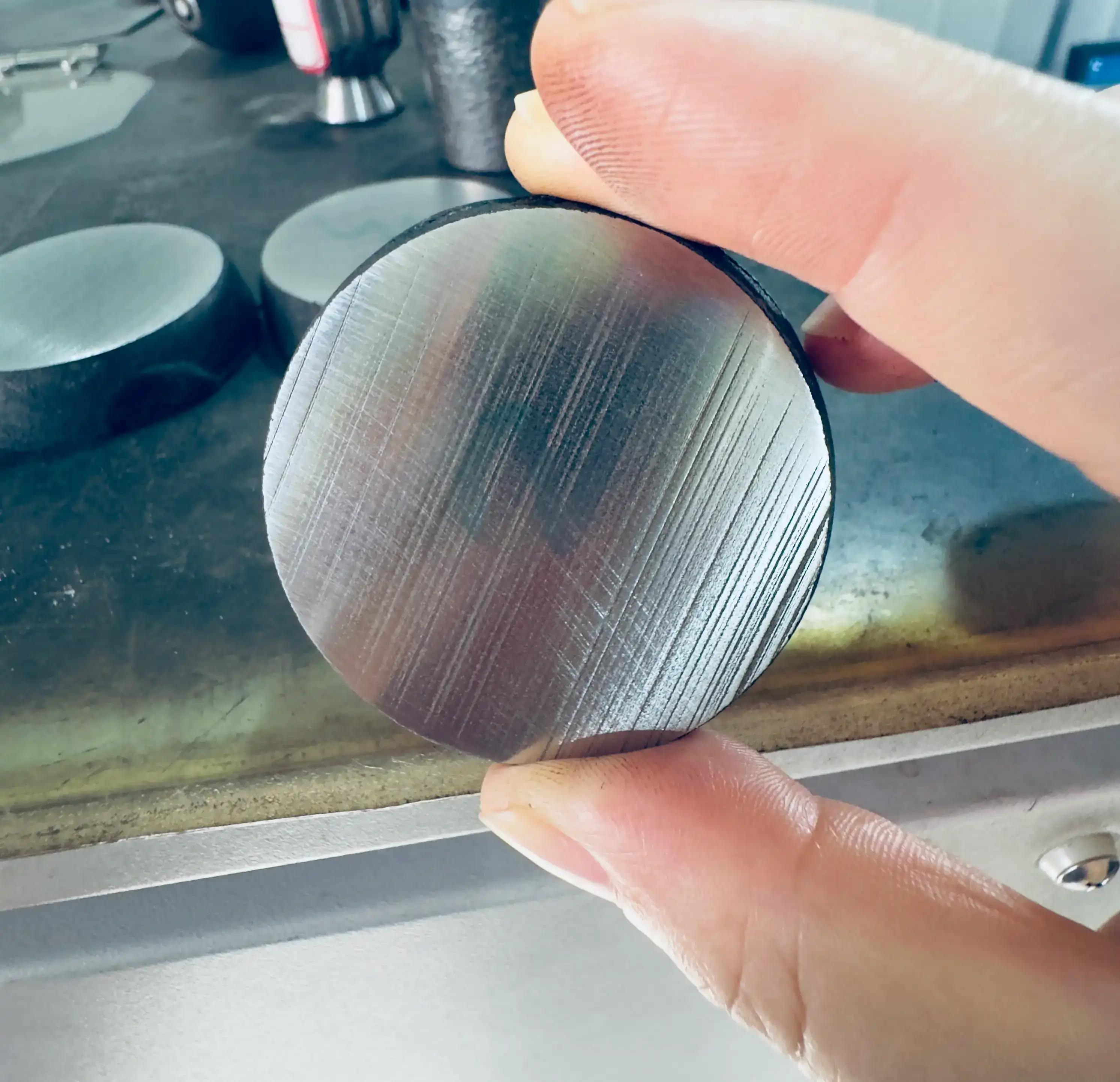

How to Clean and Maintain High Chrome Grinding Balls

.webp)

High chrome grinding balls are indispensable components in various industries, including cement production, mining, and power generation. These robust spheres play a crucial role in grinding and pulverizing materials, contributing significantly to the efficiency of industrial processes. To ensure optimal performance and longevity of it, proper cleaning and maintenance are paramount. This comprehensive guide will delve into the intricacies of caring for these essential industrial tools, providing valuable insights for professionals and enthusiasts alike.

When Should You Replace High Chrome Grinding Balls?

In the world of industrial grinding, the choice of grinding media can significantly impact operational efficiency and cost-effectiveness. High chrome grinding balls have emerged as a popular option for many industries, but the question remains: are they truly worth the investment? This article delves into the benefits, applications, and considerations surrounding it to help you make an informed decision for your grinding needs.

The Role of Casting Grinding Balls in Improving Product Quality and Reducing Costs

In today's competitive industrial landscape, manufacturers are constantly seeking ways to enhance product quality while simultaneously reducing production costs. One often overlooked but crucial element in this pursuit is the choice of grinding media, specifically casting grinding balls. These unassuming spheres play a pivotal role in various industries, from cement production to mineral processing, and their impact on both product quality and operational expenses is significant.

What factors affect the wear resistance of high chrome steel grinding media balls?

High chrome steel grinding media balls play a crucial role in various industries, including cement production, mining, and power generation. Their wear resistance is a key factor in determining their efficiency and longevity. Understanding the factors that influence the wear resistance of these grinding balls is essential for optimizing their performance and reducing operational costs. In this article, we'll explore the primary factors that affect the wear resistance of high chrome steel grinding media balls.

How Grinding Media Steel Balls Enhance Efficiency

In the world of industrial grinding processes, efficiency is paramount. One of the key components that can significantly impact the effectiveness of grinding operations is the choice of grinding media. Among the various options available, grinding media steel balls have emerged as a popular and highly efficient solution. This article delves into the ways these steel balls enhance efficiency in grinding processes across multiple industries.

High chrome grinding media balls: Cost vs. Value

In the world of industrial grinding, high chrome grinding media balls have become a topic of significant interest. These specialized grinding media, known for their durability and efficiency, are increasingly used across various industries. But as with any investment, it's crucial to weigh the cost against the value they provide. This article delves into the intricacies of high chrome grinding media balls, exploring their benefits, alternatives, and how to make the best choice for your business.

How do different grinding media materials handle extreme pH environments?

In the world of industrial grinding, the choice of grinding media can significantly impact the efficiency and effectiveness of the milling process. One crucial factor to consider is how different grinding media materials perform in extreme pH environments. This article explores the behavior of various ball mill grinding media in acidic and alkaline conditions, shedding light on their durability, performance, and potential applications.

Cylpebs Grinding Media: Case Studies from Mining Operations

.webp)

Choosing the right grinding medium is crucial for mineral processing operations since it determines the efficiency and quality of the final product. The introduction of Cylpebs grinding media changed the face of many mining operations by providing a more efficient and less expensive alternative. Case studies illustrating the influence of cylpebs in different mining environments are examined in this article.

What is the microstructure of high chrome grinding balls?

A number of sectors rely on high chrome grinding balls, such as the mining, cement, and power generating industries. The distinctive microstructure of these meticulously made balls from top grinding ball supplier is a key component to their outstanding performance and durability. In this in-depth study, we'll look at the high chrome grinding ball's microstructure in great detail to help you understand why these balls are so important for industrial use.