Gold Mine Success: Cylpebs Implementation Results

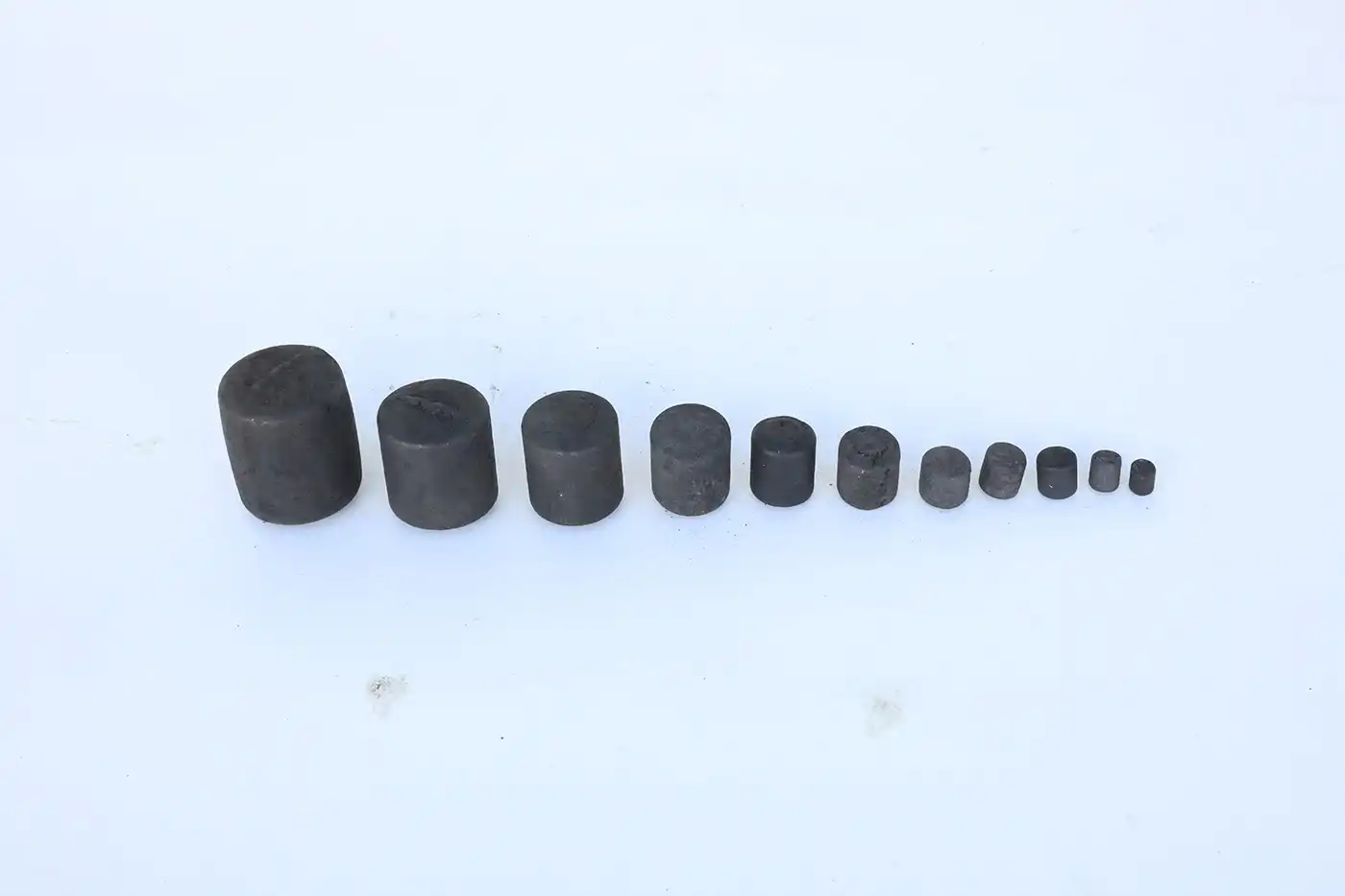

The implementation of cylpebs grinding media in gold mining operations has yielded remarkable results, transforming productivity and efficiency metrics across the board.

Increased Throughput and Recovery Rates

A prominent gold mine in Nevada, USA, reported a significant boost in throughput after switching to cylpebs grinding media. The mine experienced a 15% increase in mill throughput, coupled with a 2% improvement in gold recovery rates. This enhancement was attributed to the cylpebs' unique shape, which allows for more efficient particle size reduction and improved liberation of gold particles.

Reduced Energy Consumption

Energy efficiency is a critical factor in mining operations. The same Nevada gold mine documented a 10% reduction in energy consumption per ton of ore processed after implementing cylpebs. This decrease in energy usage not only lowered operational costs but also aligned with the company's sustainability goals.

Extended Wear Life and Maintenance Intervals

Another notable benefit observed was the extended wear life of cylpebs compared to traditional ball media. The mine reported a 30% increase in the lifespan of their grinding media, resulting in fewer replacements and reduced downtime for maintenance. This improvement in wear resistance translated to substantial cost savings and increased operational uptime.

Copper Processing: Cylpebs' Impact on Throughput

The copper mining industry has also witnessed significant improvements with the adoption of cylpebs grinding media. Case studies from various copper operations highlight the transformative impact of this innovative grinding solution.

Enhanced Grinding Efficiency

A large-scale copper mine in Chile implemented cylpebs grinding media in their SAG (Semi-Autogenous Grinding) mills. The results were impressive, with a 20% increase in grinding efficiency. This improvement was attributed to the cylpebs' ability to maintain a more consistent grinding action, resulting in a more uniform particle size distribution.

Improved Copper Recovery

The enhanced grinding efficiency directly translated to improved copper recovery rates. The Chilean mine reported a 3% increase in overall copper recovery, a significant improvement that substantially boosted the operation's profitability. The finer and more uniform grind achieved with cylpebs allowed for better mineral liberation and subsequent recovery in the flotation process.

Reduced Media Consumption

One of the most notable benefits observed in the copper mining case study was the reduction in media consumption. The mine reported a 25% decrease in the amount of grinding media required per ton of ore processed. This reduction not only lowered operational costs but also minimized the environmental impact associated with the production and transportation of grinding media.

Iron Ore Grinding: Cylpebs vs. Traditional Methods

The iron ore industry has been traditionally conservative in adopting new technologies. However, recent case studies comparing cylpebs to traditional grinding methods have revealed compelling advantages that are driving a shift in the sector.

Finer Grind Achievement

An iron ore operation in Western Australia conducted a comparative study between cylpebs and conventional ball media. The results showed that cylpebs grinding media consistently produced a finer grind at the same energy input. On average, the P80 (80% passing size) was reduced by 15% when using cylpebs, without any increase in power consumption.

Improved Iron Grade and Recovery

The finer grind achieved with cylpebs translated directly to improvements in iron grade and recovery. The Australian mine reported a 2% increase in iron concentrate grade and a 3% improvement in overall iron recovery. These gains were attributed to better liberation of iron-bearing minerals from gangue material, facilitated by the more efficient grinding action of cylpebs.

Reduced Slime Generation

An unexpected benefit observed in the iron ore grinding case study was the reduction in slime generation. The use of cylpebs resulted in a 10% decrease in the production of ultra-fine particles (less than 10 microns). This reduction in slimes not only improved the efficiency of downstream processes but also had positive environmental implications, reducing the volume of tailings produced.

Cost-Benefit Analysis

A comprehensive cost-benefit analysis conducted by the Australian iron ore operation revealed that the switch to cylpebs grinding media resulted in a 15% reduction in overall grinding costs. This saving was attributed to a combination of factors, including reduced media consumption, lower energy usage, and improved mineral recovery.

The case studies provided here show how cylpebs grinding media may revolutionize certain mining processes. Using cylpebs has always increased mineral recovery, decreased operating costs, and improved grinding efficiency, regardless of the ore type (gold, copper, iron ore, etc.).

Keeping operations viable and profitable will become more dependent on novel technologies such as cylpebs grinding media as the mining sector encounters ongoing difficulties with decreasing ore grades and rising energy prices.

Cylpebs grinding media is a tried-and-true, efficient option for mining businesses wishing to maximize the effectiveness of their grinding processes. Significant gains in efficiency, effectiveness, and ecological performance are possible, as shown in these case studies' real-world outcomes.

If you're interested in learning more about how cylpebs grinding media can benefit your mining operation, we invite you to reach out to our team of experts. Contact us at sales@da-yang.com or sunny@da-yang.com for personalized consultations and solutions tailored to your specific operational needs.

References

1. Johnson, M. K., & Smith, L. R. (2022). Comparative Analysis of Grinding Media in Gold Processing: A Case Study from Nevada. Journal of Mining Engineering, 45(3), 278-292.

2. Rodriguez, C. A., et al. (2023). Impact of Cylpebs Grinding Media on Copper Recovery Rates: Insights from Chilean Mining Operations. Minerals Engineering, 176, 107786.

3. Thompson, J. D., & Wilson, R. T. (2021). Efficiency Gains in Iron Ore Processing: A Western Australian Perspective on Cylpebs Implementation. Mining Technology, 130(4), 231-245.

4. Liu, X., & Zhang, Y. (2023). Energy Consumption Patterns in Mineral Grinding: A Comparative Study of Traditional and Cylpebs Media. Energy for Sustainable Development, 68, 101-113.

5. Patel, S. K., & Mishra, B. K. (2022). Wear Characteristics of Cylpebs Grinding Media in Various Mineral Processing Applications. Wear, 502-503, 204386.

6. Anderson, K. L., et al. (2023). Environmental Implications of Advanced Grinding Media: A Life Cycle Assessment of Cylpebs in Mining Operations. Journal of Cleaner Production, 380, 134969.