What Industries Use Grinding Balls?

Grinding balls, also known as grinding media, are spherical objects used in ball mills for various industries to grind and blend materials for use in mineral processing, paints, pyrotechnics, ceramics, among others. Understanding the diverse applications of grinding balls across different industries sheds light on their critical role in manufacturing processes and material refinement.

How do you dispose of used grinding balls?

Grinding balls are vital components used in the mining and mineral processing industries to pulverize ore and extract metals such as gold, copper, and iron. These balls endure rigorous conditions, undergoing substantial wear and tear during the grinding process. As they reach the end of their operational life, proper disposal becomes crucial to mitigate environmental impact and adhere to regulatory guidelines.

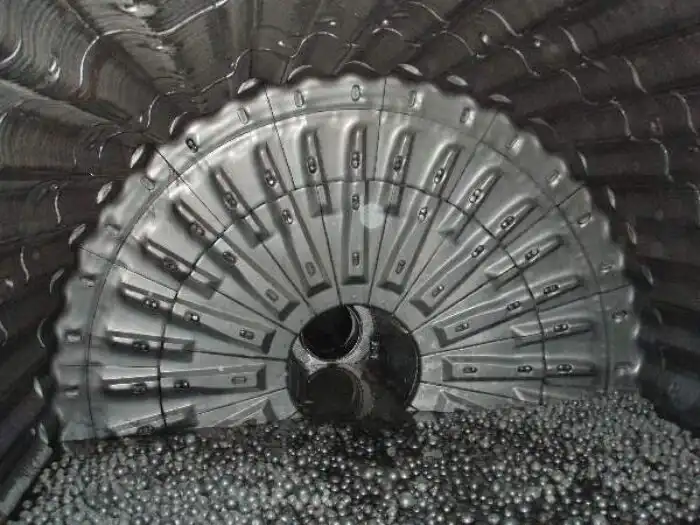

Steps to Installing High Chrome Grinding Balls

High chrome grinding balls are essential components in various industrial processes, particularly in mineral processing and cement production. These durable, wear-resistant balls play a crucial role in grinding and reducing the size of materials. In this comprehensive guide, we'll explore the steps to properly install high chrome grinding balls, ensuring optimal performance and longevity in your grinding operations.

How do high chrome steel grinding media balls influence product quality?

In the world of industrial grinding processes, the choice of grinding media can significantly impact the final product quality. High chrome steel grinding media balls have emerged as a superior option for many applications, offering a unique combination of durability, efficiency, and product enhancement. This article delves into the intricate relationship between high chrome steel grinding media balls and product quality, exploring how these specialized components contribute to superior outcomes in various industries.

How to Prevent Grinding Ball Breakage?

Grinding balls, integral to a range of industrial applications, are especially vital within the mining and cement sectors. Their primary function is to reduce ores and various materials to a finer consistency, which is essential for streamlined extraction or processing. Despite their importance, the issue of grinding balls breaking frequently poses a significant challenge to these industries. Such breakage can disrupt operations, resulting in extended periods of inactivity and escalating costs.

What certifications should grinding ball suppliers have?

Exploring the Benefits of High Chrome Grinding Balls

In the world of industrial grinding and milling, high chrome grinding balls have emerged as a game-changer. These robust, wear-resistant media are revolutionizing various industries, from cement production to mineral processing. Let's delve into the remarkable advantages of the product and discover why they're becoming the preferred choice for many manufacturers.

How do high chrome steel grinding media balls compare to ceramic media?

When it comes to industrial grinding processes, the choice of grinding media can significantly impact efficiency, cost-effectiveness, and overall performance. Two popular options in the market are high chrome steel grinding media balls and ceramic media. Both have their unique characteristics and applications, but how do they stack up against each other? Let's dive into a comprehensive comparison to help you make an informed decision for your grinding needs.

High Chrome Grinding Balls: Durability and Efficiency

In the world of industrial grinding processes, the choice of grinding media can make a significant difference in operational efficiency and cost-effectiveness. High chrome grinding balls have emerged as a superior option for various industries, including cement manufacturing, mining, and power generation. These robust spheres are designed to withstand the harsh conditions inside grinding mills while delivering exceptional performance. Let's delve into the world of high chrome grinding media and explore why they're becoming the go-to choice for many industrial applications.

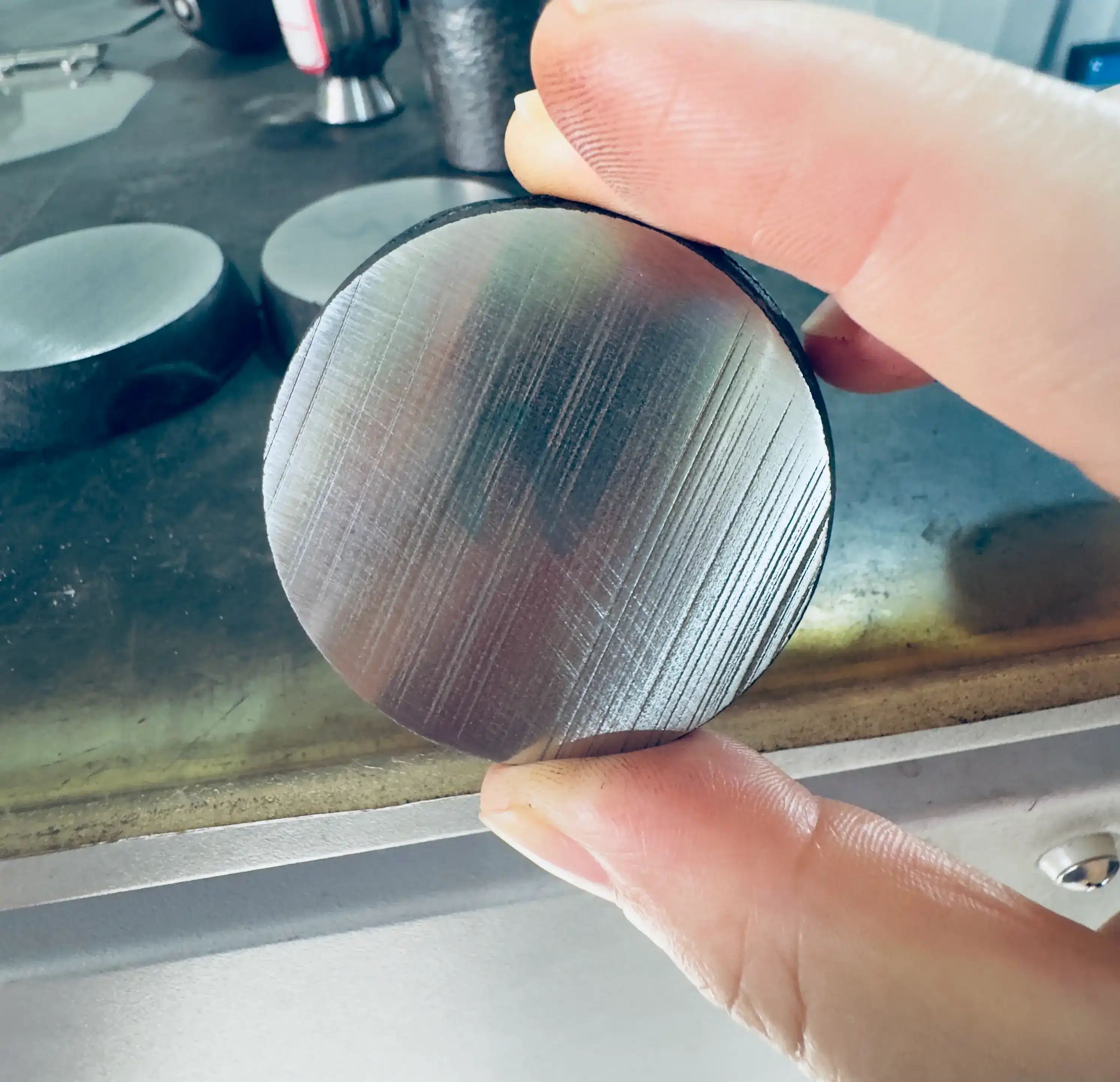

What are common defects in cast grinding balls?

Cast grinding balls play a crucial role in various industries, particularly in grinding balls mining operations. These spherical components are essential for efficient material reduction in ball mills. However, like any manufactured product, cast grinding balls can have defects that impact their performance and longevity. Understanding these common defects is vital for quality control and optimal mill operation. This article delves into the most frequent imperfections found in cast grinding balls, their causes, and methods for detection and prevention.

What is the composition of high chrome grinding media?

A vital part of many industrial grinding operations, high chrome grinding media is well-known for its long lifespan and remarkable resistance to wear. Producing high-quality grinding media with optimum compositions adapted to particular applications is NINGHU's speciality as a leading grinding media ball manufacturer. High chrome grinding media is the subject of this in-depth tutorial, which will examine its composition, effects on performance, and comparisons to other materials.

What is the role of chromium in grinding media?

Many industrial operations rely on grinding media, including mineral processing, cement manufacturing, and mining. Due to its outstanding performance and long-lasting durability, high chrome grinding media has become one of the most popular kinds of grinding media available. Here, we'll go over everything you need to know about chromium, including how it affects performance, its function in grinding media, and how to determine the appropriate chromium concentration for your needs.