What Are Grinding Balls?

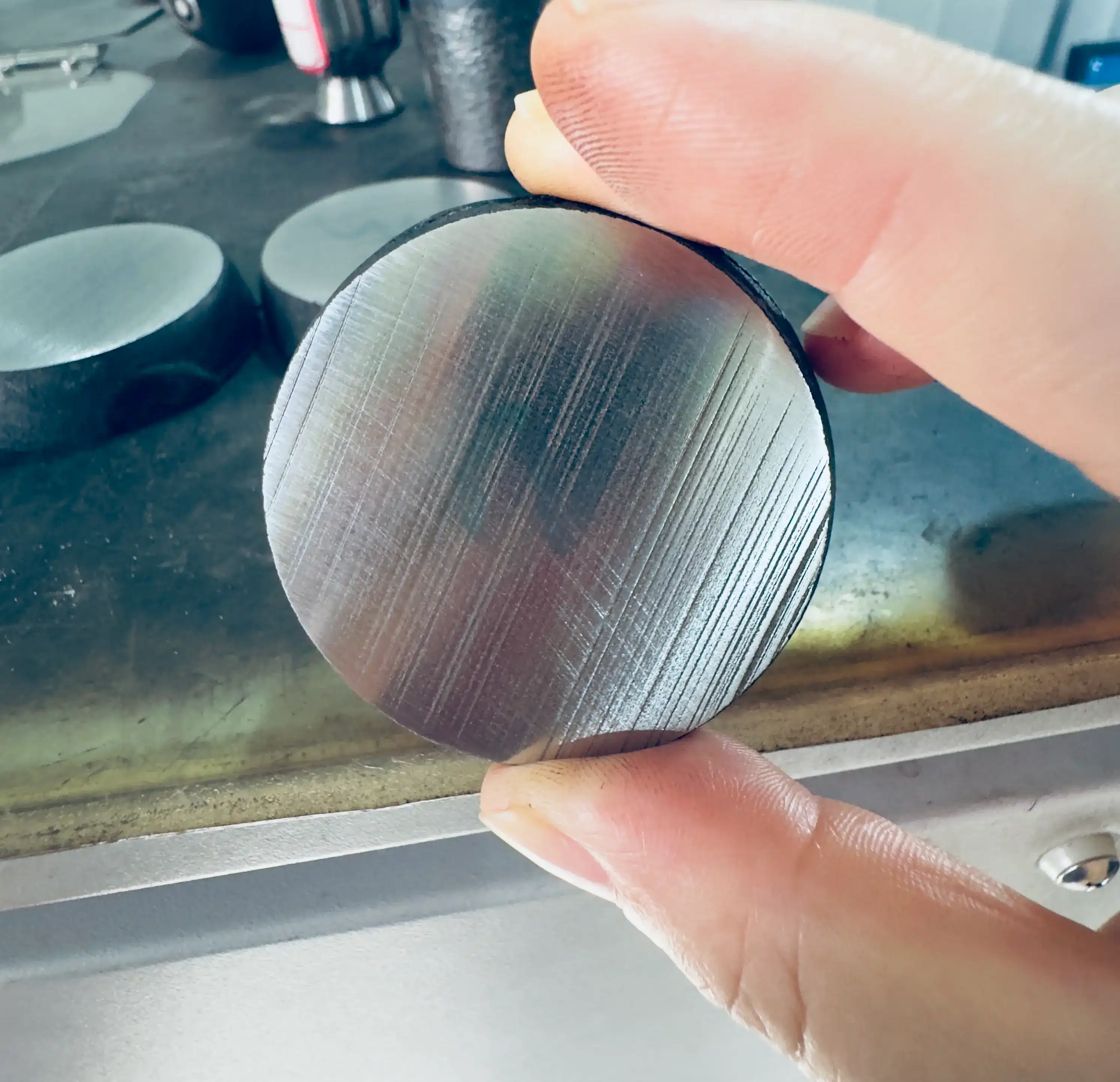

Grinding Ball play a crucial role in a variety of industries, particularly power generation, mining, and the production of cement. In grinding mills, these small, round balls are used to crush and grind materials into fine powder. The basic role of crushing balls is to work with the crushing system, guaranteeing proficient and reliable size decrease of materials. This blog will go into detail about grinding balls and answer three important questions that people who search on Google frequently ask.

Can grinding balls be recycled after use?

How Chromium Casting Grinding Balls Improve Performance in Ball Mills

In the world of industrial grinding and milling, efficiency and durability are paramount. One of the most significant advancements in this field has been the development and widespread adoption of chromium casting grinding balls. These high-performance grinding media have revolutionized the operation of ball mills across various industries, from cement production to mineral processing. Let's delve into the world of chromium casting grinding balls and explore how they enhance ball mill performance.

The Future of Grinding Media: Sustainable Solutions for Industry Challenges

In the ever-evolving landscape of industrial processes, grinding media plays a pivotal role in various sectors, from cement production to mining operations. As industries grapple with increasing demands for efficiency and sustainability, the future of it is poised for significant transformation. This article delves into the emerging trends and innovations that are shaping the next generation of grinding solutions, addressing both environmental concerns and performance requirements.

How do you choose the right size of high chrome grinding media?

Selecting the appropriate size of high chrome grinding media is crucial for optimizing your grinding process. Whether you're in the cement, mining, or power generation industry, the right choice can significantly impact your operation's efficiency and cost-effectiveness. This comprehensive guide will help you navigate the complexities of choosing the ideal size for your high chrome grinding media.

Can Grinding Balls for Ball Mill be customized?

Grinding balls for ball mill can be customized to meet specific industrial needs, improving grinding efficiency and performance. Customization options include size, material, and surface treatment. Industries like mining, cement, and power generation often require specialized grinding media to optimize milling. Tailored grinding balls help reduce wear, enhance energy efficiency, and improve output. The customization process involves collaboration between the end-user and supplier to determine optimal specifications based on application, material, and desired results. This ensures that grinding balls are suited to each operation, boosting productivity and cost-effectiveness.

How do ball mill grinding media affect the milling efficiency?

Ball mill grinding media are crucial for milling efficiency, affecting particle size reduction. Their size, shape, material composition, and wear resistance significantly impact grinding performance. High-quality media improve efficiency, reduce energy consumption, and extend equipment lifespan. Proper selection optimizes the milling process, influencing particle size distribution, grinding time, and product quality. Factors like hardness, density, and surface properties enhance grinding effectiveness. By choosing and maintaining the right media, industries can achieve better milling results, increase productivity, and lower operational costs.

What are the common applications of grinding balls in the mining sector?

Grinding Balls for Mining are essential in the mining sector, used for ore comminution, mineral liberation, and particle size reduction in ball mills. They help break down hard rock materials, such as gold, copper, and iron ores, into finer particles, enhancing the surface area for more efficient processing and mineral recovery. Grinding balls are also key in preparing mineral concentrates, aiding in separating valuable minerals from gangue materials. Their versatility spans from primary crushing to fine grinding, significantly boosting the efficiency and productivity of mineral extraction operations.

Essential Tips for Using Cement Grinding Media Balls

In the cement industry, grinding media balls play a crucial role in the production process. These cement grinding media balls are essential components in ball mills, where they crush and grind raw materials into fine particles. To ensure optimal performance and longevity of your grinding media, it's important to follow best practices for their use and maintenance. In this article, we'll explore key tips for effectively using cement grinding media balls, including maintenance strategies, wear reduction techniques, and cost optimization methods.

Innovative Applications of High Chrome Grinding Media in Industries

The world of industrial manufacturing and processing is constantly evolving, with new technologies and materials emerging to enhance efficiency and productivity. Among these innovations, high chrome grinding media has emerged as a game-changer in various sectors. This blog post explores the cutting-edge applications of chrome grinding media across different industries, showcasing how this versatile material is revolutionizing production processes and improving output quality.

How does media density influence grinding efficiency?

In the world of industrial grinding, the efficiency of the process is paramount. One crucial factor that significantly impacts grinding efficiency is the density of the grinding media used in ball mills. At NINGHU, we specialize in manufacturing high-quality grinding media, including high and low chrome casting grinding balls and cylpebs. Our extensive experience in wear-resistant materials production allows us to offer insights into how ball mill media density affects grinding efficiency. Let's delve into this topic and explore the intricacies of media density's influence on the grinding process.

How to Select the Right Cylpebs Grinding Media for Your Grinding Application?

.webp)

Selecting the appropriate cylpebs grinding media is an essential step in optimizing the efficiency and cost-effectiveness of your grinding process. Whether you're operating in the mining, cement, or chemical industry, the choice of grinding media can have a profound impact on your production output, energy consumption, and overall operational performance. Cylpebs, with their unique shape and properties, provide several advantages over traditional grinding balls, including increased surface area for grinding, better packing density, and enhanced grinding efficiency. Understanding the specific requirements of your grinding operation—such as material characteristics, throughput needs, and desired particle size—will help guide you in selecting the most suitable cylpebs. This guide aims to assist you in making an informed decision based on your unique grinding needs, ensuring that you achieve the best possible results and maximize operational efficiency.