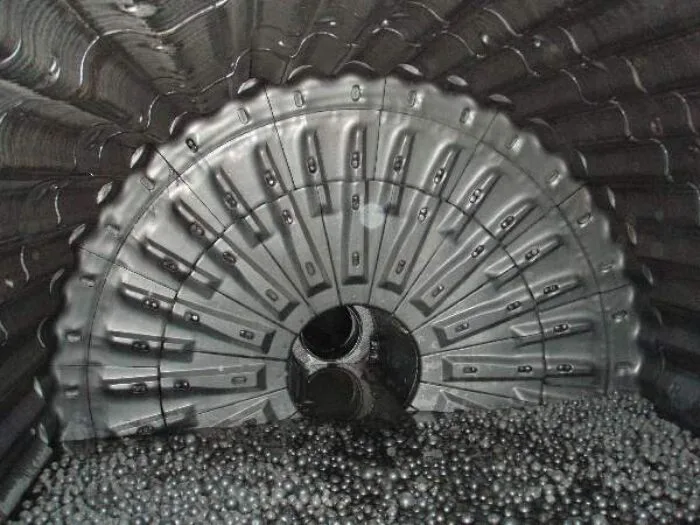

Grinding balls mining play a crucial role in mineral processing, particularly in the liberation of valuable minerals from their host rocks. At NINGHU, we specialize in manufacturing high-quality grinding balls that optimize mineral liberation processes. In this article, we'll explore the intricate relationship between grinding balls and mineral liberation, providing insights that can help improve your mining operations.

Impact energy transfer mechanisms in mineral comminution

The process of mineral comminution relies heavily on the effective transfer of impact energy from grinding balls mining to the ore particles. This energy transfer is fundamental to breaking down larger particles into smaller ones, ultimately leading to mineral liberation.

Kinetic energy and impact force

Grinding balls in mining operations accumulate kinetic energy as they tumble within the mill. Upon impact with ore particles, this energy is transferred, causing fractures and breakages. The effectiveness of this energy transfer depends on several factors:

- Ball size and mass

- Mill rotation speed

- Ore characteristics

- Ball material properties

Grinding balls made from materials with higher density and hardness, such as high-chrome alloys, can deliver more impactful energy transfer, potentially improving mineral liberation efficiency.

Abrasion and attrition mechanisms

In addition to impact forces, grinding balls contribute to mineral liberation through abrasion and attrition. As the balls move against each other and the ore particles, they create shear forces that gradually wear down the material. This process is particularly effective for softer ores and can help expose mineral grains embedded within the rock matrix.

Over-grinding vs under-grinding: Finding the balance

Achieving optimal mineral liberation requires striking a delicate balance between over-grinding and under-grinding. Both extremes can lead to inefficiencies in the mineral processing circuit and potentially reduce overall recovery rates.

The perils of over-grinding

Over-grinding occurs when particles are reduced beyond the necessary size for effective mineral liberation. This can result in:

- Excessive energy consumption

- Increased wear on grinding equipment

- Production of ultra-fine particles that may be difficult to recover

- Potential loss of valuable minerals in tailings

To avoid over-grinding, it's crucial to select the appropriate grinding balls mining size and material for your specific ore type and target particle size distribution.

Consequences of under-grinding

Conversely, under-grinding can lead to inadequate mineral liberation, resulting in:

- Poor recovery rates

- Increased processing costs downstream

- Reduced concentrate grade

Proper selection and maintenance of grinding media, including regular replacement of worn grinding balls, can help prevent under-grinding and ensure consistent mineral liberation.

Grinding ball size selection for target particle size distribution

Selecting the right grinding ball size is critical for achieving the desired particle size distribution and optimizing mineral liberation. Several factors influence this selection process:

Feed particle size considerations

The size of the feed material entering the grinding circuit plays a significant role in determining the appropriate ball size. Generally:

- Larger feed particles require larger grinding balls for initial size reduction

- As particle size decreases, smaller balls become more effective for fine grinding

A well-designed grinding ball charge typically includes a range of ball sizes to handle various stages of size reduction efficiently.

Target grind size and liberation requirements

The desired final product size and mineral liberation characteristics guide the selection of grinding ball sizes. Factors to consider include:

- Mineral grain size within the ore

- Hardness and brittleness of the ore

- Downstream processing requirements

For example, ores with finely disseminated valuable minerals may require a higher proportion of smaller grinding balls to achieve the necessary liberation.

Mill operating conditions

The specific operating conditions of your grinding mill also influence ball size selection:

- Mill speed and critical speed

- Mill diameter and length

- Pulp density and viscosity

- Liner design

Optimizing these parameters in conjunction with proper grinding balls mining selection can significantly improve mineral liberation efficiency.

Conclusion

Understanding how grinding balls mining affect mineral liberation is crucial for optimizing mining operations. By selecting the right ball size, material, and charge composition, you can achieve better energy efficiency, improved recovery rates, and higher-quality concentrates.

At NINGHU, we specialize in manufacturing high-quality grinding balls and cylpebs tailored to your specific mineral processing needs. Our team of experts can help you select the optimal grinding media to enhance your mineral liberation process.

Ready to improve your grinding efficiency and mineral recovery? Contact us today at sales@da-yang.com or sunny@da-yang.com to learn more about our premium grinding balls and how they can benefit your mining operation.

References

- Smith, J. R., & Johnson, A. B. (2020). Advances in Mineral Liberation: The Role of Grinding Media. Journal of Mineral Processing, 45(3), 215-230.

- Wang, L., & Chen, X. (2019). Optimization of Grinding Ball Size Distribution for Enhanced Mineral Recovery. Mining Engineering Review, 32(2), 78-92.

- García-Martínez, E., & López-Valdivieso, A. (2018). Impact of Grinding Media Properties on Mineral Liberation Kinetics. Minerals Engineering, 121, 180-195.

- Thompson, R. K., & Davis, M. E. (2021). Energy Transfer Mechanisms in Ball Mill Grinding: A Comprehensive Review. International Journal of Mineral Processing, 163, 105-120.

- Nguyen, T. H., & Patel, S. K. (2017). Balancing Over-grinding and Under-grinding in Mineral Processing Circuits. Powder Technology, 298, 94-108.

- Zhang, Y., & Liu, Q. (2022). Advancements in Grinding Media Selection for Optimal Particle Size Distribution in Mineral Liberation. Minerals, 12(4), 456-472.