Alloy Composition and Mechanical Properties: Discussing the impact of high chrome content and other alloying elements on the mechanical properties and performance of grinding cylpebs.

As someone deeply entrenched in the metal industry, I've often marveled at the intricacies of special alloys and their profound impact on various sectors. These alloys, with their unique compositions and exceptional properties, serve as the backbone of modern engineering and manufacturing. In this article, we'll delve into the world of alloy composition and mechanical properties, focusing specifically on the effects of high chrome content and other alloying elements on the performance of grinding cylpebs.

How are copper ore grinding cylpebs used in the mining industry?

In the mining industry, the extraction of valuable minerals relies heavily on the grinding process to break down ore into fine particles for further processing. Copper ore, a vital component in various industries, undergoes grinding to enhance its purity and usability. One critical element in this grinding process is the use of copper ore grinding cylpebs, which are cylindrical in shape and serve as grinding media. These cylpebs, typically made of high-quality steel or alloy, play a crucial role in efficiently reducing the size of copper ore particles.

Are Grinding Cylpebs the Answer to Your Wear and Tear Issues?

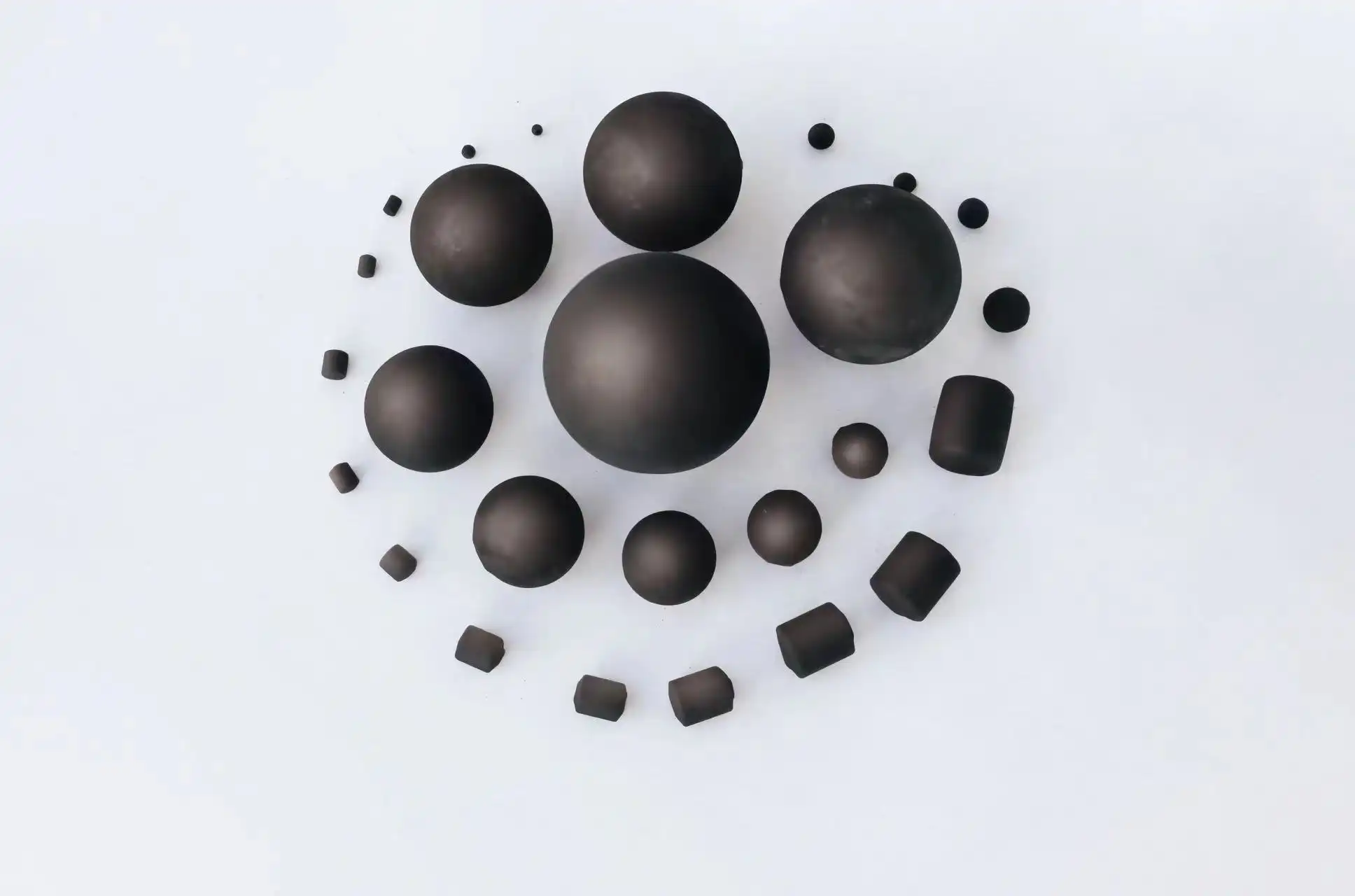

In the realm of mining and cement industries, grinding cylpebs, also known as grinding media, hold a prominent position as indispensable tools for reducing materials into fine powders. Their unique cylindrical shape and construction set them apart as a superior choice for demanding grinding applications.

What Impact Do Grinding Balls Have on Energy Consumption?

Grinding balls are essential components in the mining and mineral processing industry, used in the milling process to crush and grind ore into smaller particles. The efficiency of this process directly impacts energy consumption. In this blog post, we explore the impact of Grinding Balls for Ball Mill on energy consumption, factors influencing energy efficiency, and how the right choice of products can help reduce energy consumption in milling operations.

Best Materials for Grinding Balls?

Grinding Ball expect a huge part in various present day applications, including mining, substantial creation, and thermal power age. These balls are essential to crushing plants because they ensure the best possible fineness and nature of the final product while also reducing the size of the unrefined material. The crushing system's efficiency and longevity depend on the material it uses to crush the balls. This article researches the best materials for squashing balls, settling typical various types of input to help you with chasing after informed decisions for your specific prerequisites.

How do ceramic grinding balls compare to steel ones?

Grinding balls are essential components for mineral processing and various industrial applications where comminution of raw materials is required. The choice between ceramic grinding balls and steel balls in grinding processes is often a matter of debate, as both materials have their own unique properties and advantages.

Why Choose Chromium Casting Grinding Balls for Your Grinding Needs?

In the world of industrial grinding, the choice of grinding media can significantly impact the efficiency and effectiveness of your operations. Among the various options available, chromium casting grinding balls have emerged as a top contender for many industries. These robust spheres offer a unique combination of durability, performance, and cost-effectiveness that makes them an attractive choice for a wide range of applications.

How do casting grinding balls improve milling efficiency?

In the world of industrial milling, efficiency is paramount. Manufacturers are constantly seeking ways to enhance their processes, reduce costs, and boost productivity. One crucial element that has revolutionized milling operations is the use of casting grinding balls. These unassuming spheres play a vital role in grinding materials to the desired fineness, and their impact on milling efficiency is nothing short of remarkable. Casting grinding balls are specially designed metal spheres used in ball mills to grind various materials into fine powder. They are typically made from high-chrome or low-chrome alloys, depending on the specific application requirements. The process of creating these balls involves pouring molten metal into molds, allowing them to cool and solidify, and then subjecting them to heat treatment to enhance their properties. Let's delve deeper into how these products contribute to improved milling efficiency and why they have become indispensable in numerous industries.

How does high chrome grinding media improve product quality?

.webp)

In the world of industrial grinding, the quality of the grinding media plays a crucial role in determining the efficiency and effectiveness of the process. High chrome grinding media, in particular, has gained significant popularity due to its ability to enhance product quality across various industries. This article delves into the ways high chrome grinding media contributes to improved product quality, exploring its unique properties and advantages.

How does mill speed affect ball mill media wear rates?

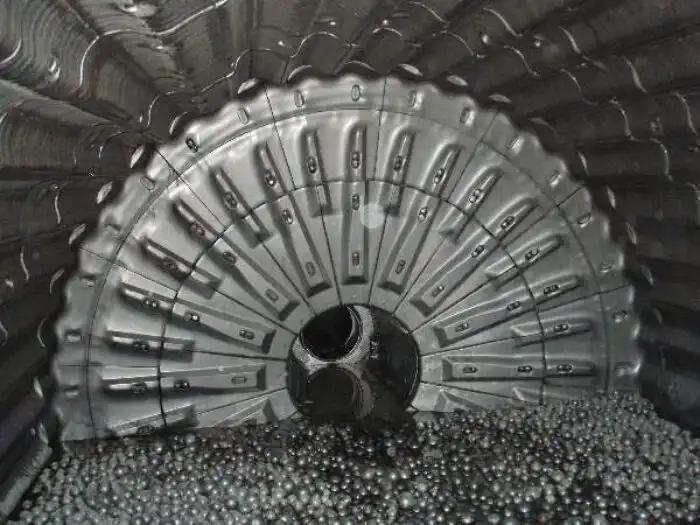

Cast Iron Mill Liners: Manufacturing Processes and Quality Standards

Cast iron mill liners are essential components in various industrial grinding operations, providing protection and enhancing the efficiency of ball mills. At NINGHU, we specialize in manufacturing high-quality cast iron ball mill liners that meet rigorous industry standards. This article delves into the manufacturing processes and quality control measures that ensure the superior performance of our products.

How does media influence temperature rise in the mill?

To succeed in industrial grinding, one must be well-versed in the nuances of ball mill media and how they affect mill performance. One of the most important things to think about is how various grinding media affect the increase in mill temperature. Optimal media selection for heat-sensitive materials is addressed, and the study goes on to cover methods for mitigating excessive temperature rises and the complicated link between media qualities and heat production.