Are Cylpebs Grinding Media Environmentally Friendly?

Grinding Cylpebs media are widely utilized in industrial grinding operations due to their impressive attributes such as high hardness, excellent wear resistance, and overall efficiency. These properties make them an appealing choice for applications requiring effective particle size reduction. However, despite their technical advantages, there are growing environmental concerns associated with the production process of high-chrome steel, the primary material used in manufacturing cylpebs.

What Factors Influence the Selection of Grinding Balls?

Grinding balls are essential components for the efficient and effective comminution of ores in mining and cement industries. However, selecting the right products for a specific application can be challenging due to various influencing factors. In this blog, we will explore the key factors that influence the selection of products and how to make an informed decision.

What are Ceramic Grinding Balls?

Earthenware Grinding Ball are fundamental parts in the fine crushing or processing cycle of different materials. They are mostly used in mining, ceramics, and coatings, where purity and long-term use are important. These balls are intended to be exceptionally productive in crushing materials to the ideal fineness and are a basic piece of crushing tasks around the world.

What industries commonly use grinding balls?

What are the benefits of using casting grinding balls over other types?

.webp)

In the world of industrial grinding, the choice of grinding media can significantly impact the efficiency and effectiveness of your operations. Among the various options available, casting grinding balls have emerged as a popular choice for many industries. This article explores the unique advantages of using it compared to other types of grinding media.

Innovations in Chromium Casting Grinding Balls: Trends and Future Directions

How does high chrome grinding media contribute to cost savings?

In the world of industrial grinding, high chrome grinding media has emerged as a game-changer, offering substantial cost savings for businesses across various sectors. These specialized grinding balls and cylpebs, crafted with high chromium content, have revolutionized the grinding process, delivering exceptional performance and longevity. Let's delve into the ways high chrome grinding media contributes to cost savings and why it's becoming the preferred choice for industries worldwide.

What trends are shaping the future of grinding balls in mining?

The future of Grinding Balls for Mining is being shaped by several significant trends that are transforming the industry. Sustainability and environmental consciousness are driving the development of eco-friendly grinding media with reduced carbon footprints. Advancements in material science are leading to the creation of more durable and efficient grinding balls, capable of withstanding harsh mining conditions while improving overall performance. Digitalization and automation are revolutionizing the manufacturing and quality control processes, ensuring consistent production of high-quality grinding balls. The growing demand for rare earth elements and critical minerals is pushing the boundaries of grinding technology, requiring specialized grinding media for these complex ores. Additionally, the shift towards circular economy principles is encouraging the recycling and reuse of grinding balls, minimizing waste and maximizing resource efficiency. These trends collectively point towards a future where grinding balls in mining will be more sustainable, efficient, and technologically advanced, meeting the evolving needs of the mining industry while addressing environmental concerns.

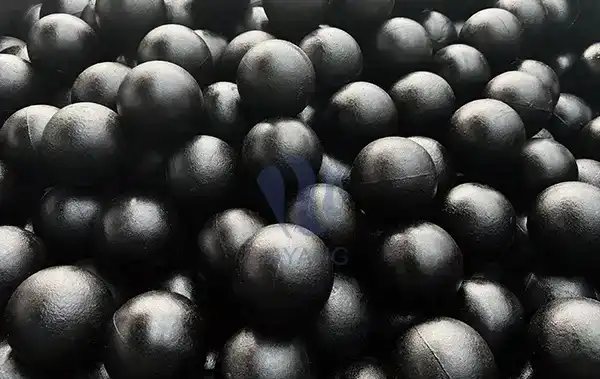

High-Quality Steel Balls for Industrial Ball Mills

.webp)

In the world of industrial grinding and milling, the quality of your equipment can make or break your operation. At the heart of many milling processes lie steel balls – the unsung heroes of material reduction. These seemingly simple spheres play a crucial role in transforming raw materials into finely ground particles, essential for industries ranging from mining to cement production. Let's dive into the world of high-quality steel balls for ball mill and discover why they're indispensable for optimal milling performance.

How Grinding Media Affects Ball Mill Grinding Efficiency

In the world of industrial grinding, the choice of grinding media plays a pivotal role in determining the efficiency and effectiveness of ball mill operations. Whether you're involved in cement production, mining, or any other industry that relies on ball mills, understanding the impact of grinding media is crucial for optimizing your processes. In this comprehensive guide, we'll explore how different types of grinding media in ball mill operations affect grinding efficiency, and provide insights to help you make informed decisions for your specific applications.

How to select ball mill media for wet grinding applications?

Wet grinding applications in ball mills are crucial processes in various industries, including mining, cement production, and chemical processing. Selecting the right ball mill media is essential for achieving optimal grinding efficiency, product quality, and cost-effectiveness. This comprehensive guide will explore the key factors to consider when choosing ball mill media for wet grinding applications, helping you make informed decisions to enhance your grinding operations.

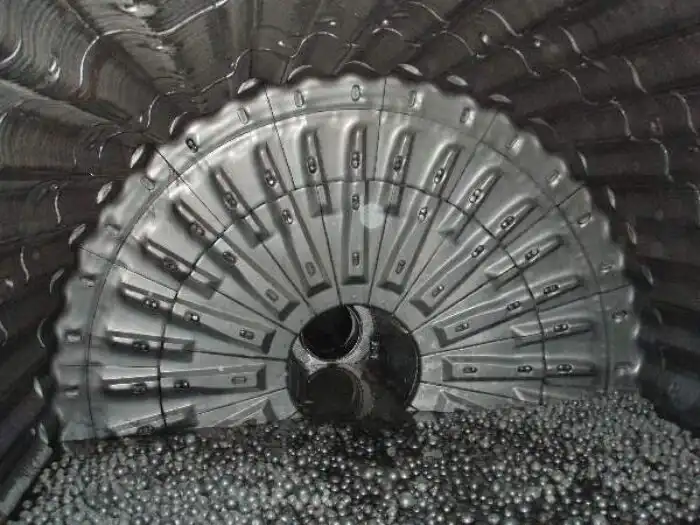

How to Select the Right Cast Iron Mill Liner for Your Application?

Selecting the appropriate cast iron mill liners are crucial for optimizing grinding efficiency and prolonging the lifespan of your ball mill. This comprehensive guide will walk you through the essential factors to consider when choosing the ideal liner for your specific application. Whether you're in the mining, cement, or power generation industry, understanding these key elements will help you make an informed decision and improve your milling operations.