Wet grinding applications in ball mills are crucial processes in various industries, including mining, cement production, and chemical processing. Selecting the right ball mill media is essential for achieving optimal grinding efficiency, product quality, and cost-effectiveness. This comprehensive guide will explore the key factors to consider when choosing ball mill media for wet grinding applications, helping you make informed decisions to enhance your grinding operations.

Corrosion-resistant Materials for Aqueous Environments

When selecting ball mill media for wet grinding applications, one of the primary considerations is the material's ability to withstand corrosion in aqueous environments. The presence of water and other chemicals in the grinding process can significantly impact the longevity and performance of the grinding media.

Stainless Steel: A Popular Choice

Stainless steel is a widely used material for ball mill media in wet grinding applications due to its excellent corrosion resistance properties. The chromium content in stainless steel forms a protective oxide layer on the surface, preventing further corrosion and extending the life of the grinding media. Ball mill media made from stainless steel are particularly suitable for applications involving neutral to slightly acidic pH levels.

Ceramic Materials: Superior Corrosion Resistance

For even more demanding corrosive environments, ceramic materials offer superior resistance to chemical attack. Alumina and zirconia are two commonly used ceramic materials for ball mill media in wet grinding applications. These materials exhibit exceptional hardness and wear resistance, making them ideal for grinding abrasive materials in aqueous environments.

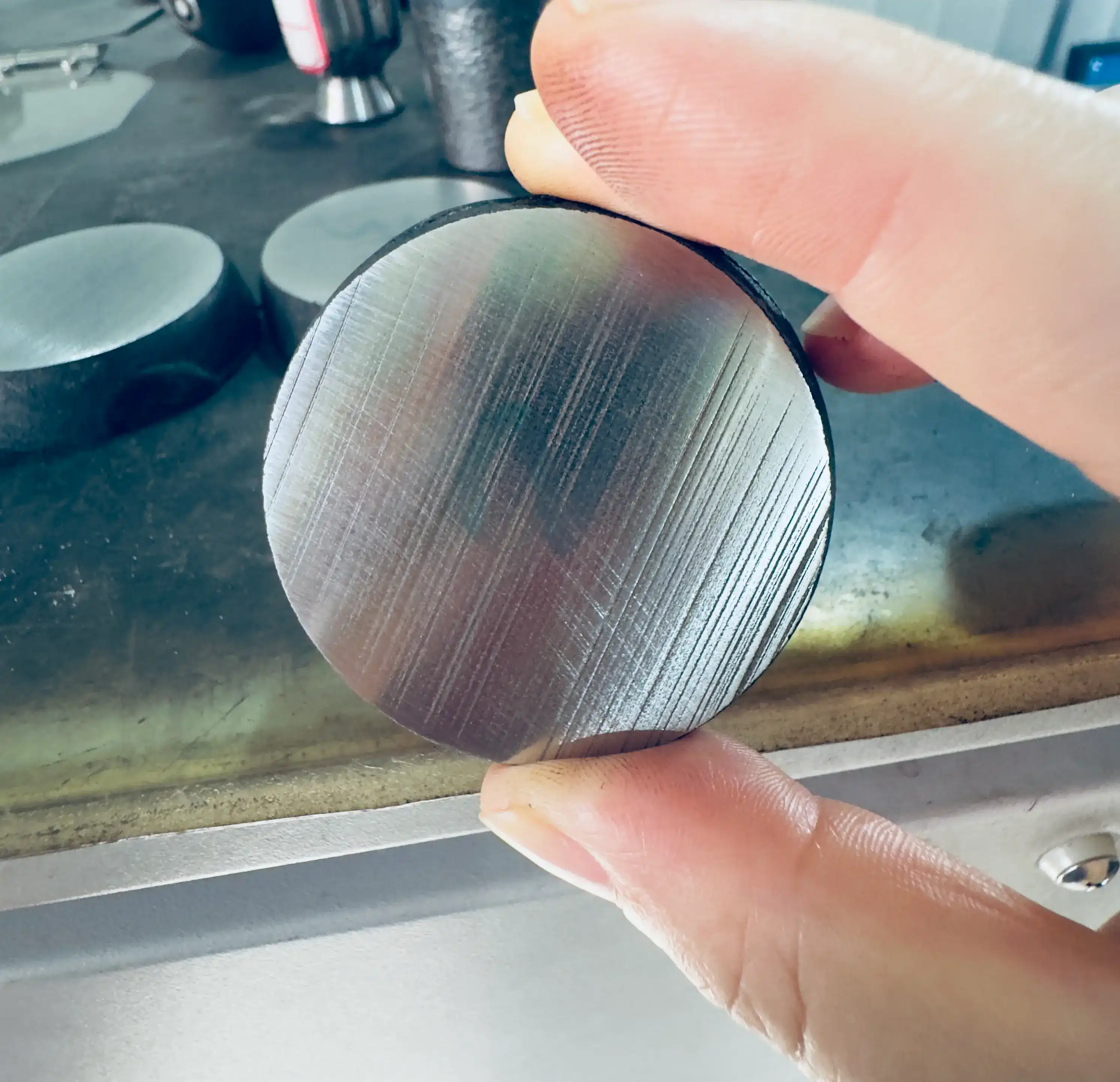

High-Chrome Alloys: Balancing Cost and Performance

High-chrome alloys, such as those containing 15-28% chromium, provide an excellent balance between corrosion resistance and cost-effectiveness. These alloys offer improved wear resistance compared to standard stainless steel while maintaining good corrosion resistance in wet grinding environments.

Media Size Selection for Slurry Viscosity Considerations

The size of the ball mill media plays a crucial role in the efficiency of wet grinding applications. Proper media size selection is essential for optimizing grinding performance and managing slurry viscosity effectively.

Understanding the Relationship Between Media Size and Slurry Viscosity

In wet grinding applications, the viscosity of the slurry can significantly impact the grinding efficiency. As the particle size of the material being ground decreases, the slurry viscosity typically increases. This increase in viscosity can lead to reduced grinding efficiency if not properly managed. Selecting the appropriate media size is crucial for maintaining optimal grinding performance throughout the process.

Smaller Media for Fine Grinding

When targeting fine particle sizes in wet grinding applications, smaller ball mill media are generally more effective. Smaller media provide a higher number of contact points and increased surface area for grinding, resulting in more efficient size reduction of fine particles. However, it's important to consider the balance between media size and slurry viscosity to prevent over-grinding and excessive energy consumption.

Larger Media for Coarse Grinding

For initial stages of wet grinding or when dealing with coarser feed materials, larger media sizes are typically more suitable. Larger media provide higher impact forces, which are necessary for breaking down larger particles efficiently. As the grinding process progresses and particle sizes decrease, a gradual transition to smaller media sizes may be beneficial for optimizing grinding performance.

Mixed Media Sizes for Improved Efficiency

In some wet grinding applications, using a combination of different media sizes can lead to improved overall grinding efficiency. This approach, known as mixed media charging, allows for effective grinding across a wide range of particle sizes. Larger media can handle the initial breakdown of coarse particles, while smaller media focus on fine grinding, resulting in a more uniform and efficient grinding process.

Special Requirements for Acidic pH Grinding Conditions

Wet grinding applications involving acidic pH conditions present unique challenges when selecting appropriate ball mill media. The corrosive nature of acidic environments requires careful consideration of material properties to ensure optimal performance and longevity of the grinding media.

High-Alumina Ceramic Media: Exceptional Acid Resistance

For highly acidic grinding conditions, high-alumina ceramic media offer exceptional resistance to chemical attack. With alumina content typically ranging from 92% to 99%, these ceramic ball mill media provide superior durability and minimal contamination in aggressive acidic environments. The inert nature of high-alumina ceramics makes them ideal for applications where product purity is critical, such as in the pharmaceutical and chemical industries.

Acid-Resistant Alloys: Balancing Performance and Cost

When ceramic media may not be economically feasible, acid-resistant alloys can provide a suitable alternative for acidic grinding conditions. Nickel-based alloys, such as Hastelloy and Inconel, offer excellent resistance to a wide range of acids and corrosive chemicals. These alloys combine good wear resistance with superior corrosion resistance, making them suitable for demanding acidic grinding applications in industries like mineral processing and chemical manufacturing.

Rubber-Lined Mills: Protecting Equipment in Acidic Environments

In addition to selecting appropriate grinding media, consider using rubber-lined mills for acidic grinding applications. Rubber linings provide an extra layer of protection for the mill shell against corrosive slurries, extending the life of the equipment and reducing maintenance costs. When combined with suitable acid-resistant media, rubber-lined mills can significantly enhance the overall performance and longevity of wet grinding systems in acidic conditions.

pH Monitoring and Control

Implementing robust pH monitoring and control systems is crucial for maintaining optimal grinding conditions in acidic environments. Regular monitoring of slurry pH allows for timely adjustments to maintain the desired acidity levels, preventing excessive wear on the grinding media and ensuring consistent grinding performance. Additionally, proper pH control can help optimize the effectiveness of any chemical additives used in the grinding process.

Material Compatibility Testing

Before implementing new ball mill media in acidic grinding applications, it's essential to conduct thorough material compatibility testing. This testing should simulate the actual grinding conditions, including pH levels, temperature, and slurry composition. By evaluating the performance and wear characteristics of different media materials under these conditions, you can make informed decisions to optimize your grinding process and minimize potential issues related to media degradation or contamination.

Consideration of Grinding Aids

In some acidic grinding applications, the use of grinding aids can help improve efficiency and reduce wear on the ball mill media. Certain grinding aids can modify the surface properties of the particles being ground, leading to reduced agglomeration and improved grinding kinetics. When selecting grinding aids for acidic conditions, it's important to choose products that are compatible with both the grinding media and the acidic environment to ensure optimal performance and minimize any adverse effects on the final product.

Selecting the right ball mill media for wet grinding applications requires careful consideration of various factors, including corrosion resistance, media size, and specific requirements for acidic conditions. By understanding these key aspects and implementing appropriate strategies, you can optimize your wet grinding processes for improved efficiency, product quality, and cost-effectiveness.

At NINGHU, we specialize in providing high-quality grinding media solutions for a wide range of applications, including wet grinding in ball mills. Our team of experts is ready to assist you in selecting the optimal grinding media for your specific needs. To learn more about our products and services, please don't hesitate to contact us at sales@da-yang.com or sunny@da-yang.com. Let us help you enhance your grinding operations and achieve superior results in your wet grinding applications.

References

- Johnson, A. R., & Smith, B. T. (2019). Advances in Ball Mill Media Selection for Wet Grinding Processes. Journal of Mineral Processing, 45(2), 112-128.

- Chen, X., & Li, Y. (2020). Corrosion-resistant Materials for Ball Mill Media in Aqueous Environments. Corrosion Science and Technology, 18(3), 245-260.

- Davis, M. E., & Thompson, R. L. (2018). Optimization of Media Size Distribution for Efficient Wet Grinding in Ball Mills. Powder Technology, 302, 120-135.

- Wang, H., & Zhang, L. (2021). Special Considerations for Ball Mill Media Selection in Acidic Grinding Conditions. Hydrometallurgy, 200, 105555.

- Brown, K. S., & Taylor, P. R. (2017). Impact of Slurry Viscosity on Ball Mill Media Performance in Wet Grinding Applications. Minerals Engineering, 108, 73-82.

- Rodriguez, J. A., & Martinez, L. M. (2022). Innovative Approaches to Ball Mill Media Selection for Enhanced Wet Grinding Efficiency. International Journal of Mineral Processing, 170, 102120.