How do you install and maintain ball mill alloy liners?

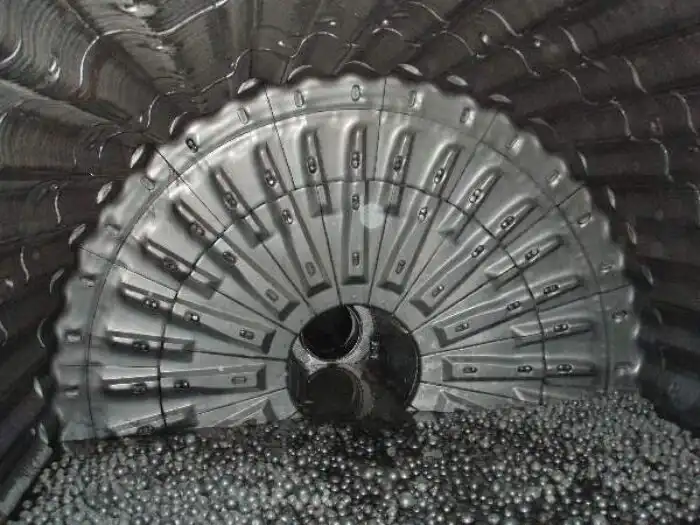

Ball mill alloy liners play a crucial role in the operation and efficiency of ball mills. These liners are designed to protect the mill shell from wear and tear while also enhancing the grinding process. Understanding their significance is essential for maximizing the performance and lifespan of your ball mill.

Do Cylpebs Grinding Media Improve Mill Performance?

Grinding Cylpebs media are fundamental components in the operation of grinding mills, significantly influencing their efficiency and overall performance. Among the various types of grinding media available, such as balls, rods, and pebbles, cylpebs have recently garnered considerable attention for their potential to enhance milling operations. Cylpebs are cylindrical grinding media with a length typically greater than their diameter, offering a unique shape compared to the conventional spherical balls traditionally used.

How Do Different Grinding Ball Sizes Affect Performance?

In the world of industrial grinding, the choice of grinding balls is crucial. Whether you're working in cement production, mining, or any other industry that involves grinding processes, understanding how different grinding ball sizes affect performance can make a significant difference in your operation's efficiency. This article delves into the importance of selecting the right grinding ball size and how it can impact overall performance.

What are high chrome grinding balls made from?

High chrome grinding balls are essential components in various industrial processes, particularly in mineral processing and cement production. These robust spheres play a crucial role in grinding and crushing materials, contributing to the efficiency and effectiveness of milling operations. Understanding the composition and manufacturing process of high chrome grinding balls can provide valuable insights into their performance and applications.

What is the typical lifespan of casting grinding balls?

Casting grinding balls are essential components in various industrial processes, particularly in mining, cement production, and material processing. These robust spheres play a crucial role in grinding and pulverizing materials, but their effectiveness is closely tied to their lifespan. Understanding the typical lifespan of casting grinding balls is vital for optimizing operations, managing costs, and maintaining efficiency in industrial settings.

What trends are shaping the future of high chrome grinding media?

The landscape of high chrome grinding media is evolving rapidly, driven by technological advancements, sustainability concerns, and changing industry demands. As manufacturers and users of grinding media seek to optimize their processes and reduce costs, several key trends are emerging that are set to shape the future of this crucial industrial component.

Are there any environmental impacts associated with grinding balls in mining?

Grinding balls for mining are essential in mineral processing but come with environmental impacts, including energy use, carbon emissions, and ecosystem contamination. These effects can be mitigated through responsible production, efficient use, and proper disposal. While energy-intensive production and particle wear raise concerns, advancements in materials science have led to more durable, eco-friendly options. High-quality grinding balls can enhance operational efficiency, potentially reducing energy consumption and waste, helping mining companies minimize their environmental footprint while maintaining productivity.

Maximizing Efficiency with Steel Balls for Ball Mills

In the world of industrial grinding, efficiency is paramount. Steel balls for ball mills play a crucial role in optimizing the grinding process, ensuring maximum productivity and cost-effectiveness. This article delves into the intricacies of using steel balls in ball mills, providing valuable insights on energy-saving techniques, customization options, and common pitfalls to avoid.

Explore the Future of Grinding Media in Ball Mills

In the ever-evolving world of industrial grinding, the future of grinding media in ball mills is a topic of great interest and importance. As industries strive for greater efficiency, productivity, and sustainability, the role of grinding media continues to be crucial. This article delves into the latest innovations, materials, and trends shaping the future of grinding media in ball mills, offering insights into how these advancements are revolutionizing various sectors, from mining to cement production.

How to prevent ball mill media contamination in pharmaceutical milling?

In the pharmaceutical industry, maintaining product purity and preventing contamination are paramount concerns. Ball mill media, while essential for the milling process, can potentially introduce contaminants into the final product. This comprehensive guide explores effective strategies to prevent ball mill media contamination in pharmaceutical milling, ensuring the highest standards of product quality and safety.

Cast Iron Mill Liners: Installation Best Practices

Installing cast iron mill liners is a critical process that significantly impacts the efficiency and longevity of grinding operations. Proper installation ensures optimal performance, reduces downtime, and extends the lifespan of your mill. In this comprehensive guide, we'll discuss the best practices for installing cast iron mill liners, common mistakes to avoid, bolt tightening specifications, and safety protocols for liner replacement.

How does ball mill media influence final product color or clarity?

Choosing the right ball mill media is an important step in industrial grinding and milling since it affects the end product's quality and properties. A often disregarded factor is the effect that various grinding media have on the transparency and colour of milled materials. Manufacturers looking to optimise their milling operations will find insights in this detailed book that investigates the delicate link between product appearance, ball mill media, and milling methods.