How do you calculate grinding media in a ball mill?

The determination of the quantity of grinding media that is required in a ball mill is an essential step in ensuring the effectiveness of the milling process. Grinding media like ceramic balls, flint pebbles, and stainless steel balls are needed to break down the material in the mill. The efficiency and nature of the processing process are directly influenced by the type and quantity of grinding cylpebs used.

How Can Grinding Balls Reduce Grinding Media Consumption?

In industries like cement production, mining, and power generation, grinding media is an essential component of the milling process. However, the cost of grinding media can be substantial, especially when considering the large volumes required. Reducing grinding media consumption is not just about cutting costs; it's also about improving efficiency, prolonging equipment life, and minimizing environmental impact. But how can grinding balls contribute to this goal? In this article, we'll explore how the right choice of grinding balls can help reduce grinding media consumption while maintaining or even enhancing operational efficiency.

What is the Hardness of Grinding Balls?

Grinding Ball are a necessary part of a lot of industrial processes, especially mining and ore processing, where they are used to extract valuable minerals from ore. The effectiveness and longevity of grinding balls are directly impacted by their hardness, so knowing their hardness is essential. Hardness impacts how well the balls wear out materials and oppose misshapening under pressure, eventually influencing the effectiveness of the whole processing process.

Can grinding balls be used for both wet and dry milling?

Grinding balls are essential components in ball milling operations, crucial for pulverizing materials into fine particles in both wet and dry conditions. Understanding their versatility is key to optimizing milling processes for various applications. Grinding balls play a vital role in the process of ball milling, which is widely used in various industries for the production of powders and materials. Whether in wet or dry milling applications, these spheres are capable of effectively reducing the size of particles, enhancing mixing processes, and facilitating chemical reactions.

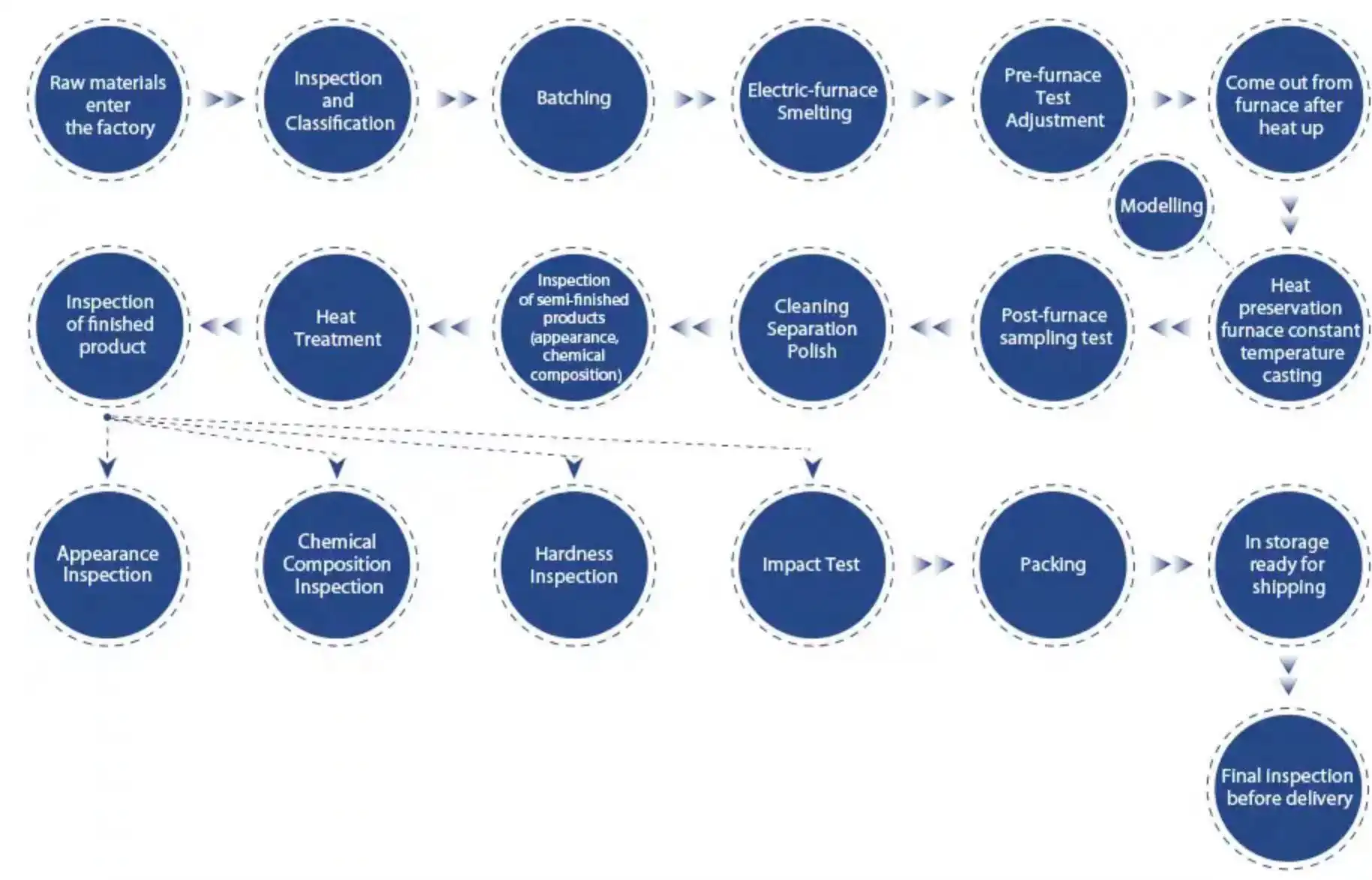

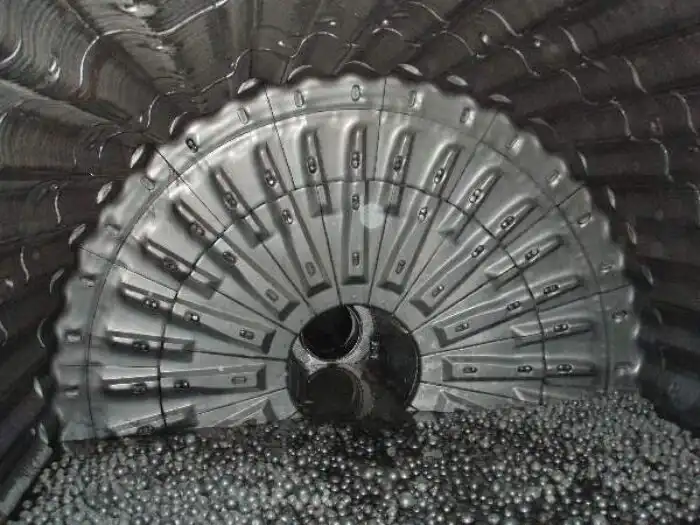

How are high chrome grinding balls produced?

In the world of industrial grinding, high chrome grinding balls play a crucial role in enhancing efficiency and durability. These robust spheres are essential components in various industries, including cement production, mining, and power generation. But have you ever wondered about the intricate process behind their creation? Let's delve into the fascinating world of high chrome grinding ball production and uncover the secrets behind their exceptional performance.

What factors influence the quality of casting grinding balls?

In the world of industrial grinding, casting grinding balls play a crucial role in various sectors, including cement production, mining, and power generation. These spherical metallic tools are essential for breaking down materials into fine particles, and their quality can significantly impact the efficiency and effectiveness of grinding operations. Understanding the factors that influence the quality of casting grinding balls is vital for manufacturers and end-users alike. Let's delve into the key elements that determine the performance and durability of these indispensable grinding media.

Milling Balls: Types and Applications

In the world of industrial processing, milling balls play a crucial role in grinding and refining materials across various sectors. These unassuming spheres are the workhorses of ball mills, tirelessly breaking down substances into finer particles. From the rugged terrains of mining operations to the pristine environments of pharmaceutical labs, milling balls are indispensable tools that shape the products we use daily. Let's dive into the fascinating world of these grinding powerhouses and explore their types, applications, and the latest innovations driving their evolution.

How high chrome grinding media balls Boosts Efficiency

What is the composition of high chrome steel grinding media balls?

High chrome steel grinding media balls are essential components in various industrial processes, particularly in mineral processing, cement production, and mining operations. These durable and efficient grinding tools are designed to withstand extreme conditions while delivering optimal performance. Understanding the composition of high chrome steel grinding media balls is crucial for professionals in these industries to make informed decisions about their grinding equipment. The composition of high chrome steel grinding media balls plays a significant role in determining their performance, wear resistance, and overall lifespan. By delving into the intricate details of their makeup, we can gain valuable insights into why these grinding media are preferred in numerous applications.

What forces act on ball mill grinding media during rotation?

Ball mill grinding media play a crucial role in the comminution process, reducing particle sizes through a complex interplay of forces. Understanding these forces is essential for optimizing mill performance and achieving desired product characteristics. In this comprehensive guide, we'll explore the various forces acting on it during rotation, their effects on particle breakage, and how they contribute to the overall grinding efficiency.

Cylpebs Grinding Media: Impact on Particle Size Distribution

.webp)

The efficiency and overall efficacy of particle size reduction in industrial grinding operations are largely dependent on the selection of the grinding medium. Among the many available options, cylpebs grinding media has gained significant popularity due to its unique shape, exceptional qualities, and reliable performance characteristics. Unlike spherical balls, cylpebs grinding media provides greater surface contact and more uniform interaction with materials, leading to enhanced grinding efficiency and improved particle size control. These advantages translate into lower energy consumption, reduced wear on equipment, and more consistent product outcomes. This makes them especially valuable in industries such as cement manufacturing, mining, and mineral processing, where controlled particle size distribution directly impacts product quality, process stability, and overall cost-effectiveness. This article explores the multiple benefits and practical applications of cylpebs grinding media across different sectors, highlighting its growing role in optimizing modern grinding operations.

Top High Chrome Grinding Media Uses in Mining You Should Know in 2025

As the mining industry continues to advance, the importance of efficient and durable grinding media becomes increasingly apparent. High chrome grinding media balls have emerged as a crucial component in modern mining operations, offering superior wear resistance and enhanced performance. In this article, we'll explore the top uses of high chrome grinding media in mining that industry professionals should be aware of in 2025.