Mining Applications of Grinding Balls

As a pivotal component within the realm of mining operations, grinding balls play a crucial role in the extraction and refinement of minerals. In this article, I delve into the multifaceted applications of grinding balls within the mining industry, exploring their significance, composition, efficiency factors, technological advancements, and broader implications on the environment and economy.

How to Recycle Grinding Balls?

Grinding Ball are fundamental apparatuses in different modern cycles, especially in mining and metal handling. However, their use causes wear and tear, making them eventually unusable in their original form. The economic benefits of recycling grinding balls outweigh the environmental benefits. The efficacy, benefits, and feasibility of recycling grinding balls are examined in this article.

What is the impact of grinding ball composition on milling results?

Top Trends in Casting Grinding Balls: Innovations Shaping the Future of Grinding Media

The world of industrial grinding is experiencing a renaissance, with casting grinding balls at the forefront of this evolution. As industries strive for greater efficiency and sustainability, the demand for innovative grinding media solutions continues to grow. This article explores the cutting-edge trends that are revolutionizing the casting grinding balls sector, offering insights into the future of grinding technology.

Exploring the Environmental Impact of Casting Grinding Balls in Industrial Processes

In the realm of industrial manufacturing, casting grinding balls play a pivotal role in various processes, particularly in the mining, cement, and power generation sectors. These spherical components, crafted from high-chrome or low-chrome materials, are essential for grinding and pulverizing raw materials. However, as industries worldwide shift towards more sustainable practices, it's crucial to examine the environmental implications of producing and utilizing casting grinding balls. This article delves into the ecological footprint of these industrial tools and explores potential avenues for minimizing their environmental impact.

How is the hardness of high chrome steel grinding media balls measured?

In the world of industrial grinding, the hardness of grinding media plays a crucial role in determining the efficiency and effectiveness of the grinding process. High chrome steel grinding media balls, known for their exceptional durability and wear resistance, are widely used across various industries. But have you ever wondered how the hardness of these robust spheres is measured? Let's delve into the intricacies of hardness measurement for high chrome steel grinding media balls and uncover the significance of this essential characteristic.

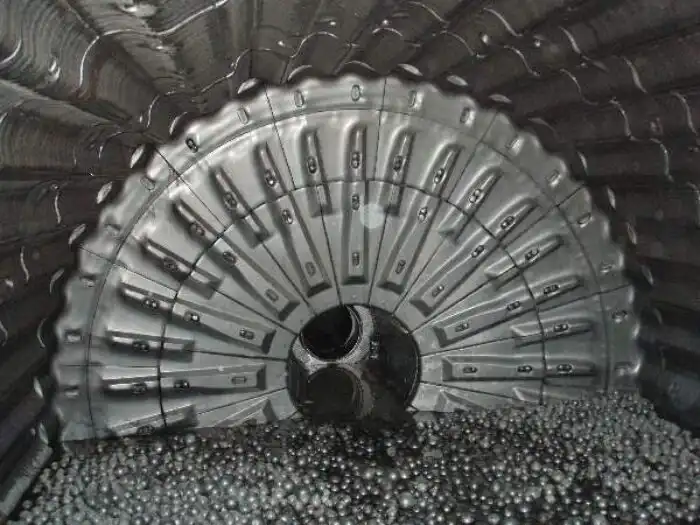

Grinding Media Steel Balls: Types and Applications

.webp)

In the world of industrial processing, grinding media steel balls play a crucial role in transforming raw materials into valuable resources. These small yet mighty components are the unsung heroes of various industries, from mining to cement production. Let's dive into the fascinating world of grinding media steel balls, exploring their types, applications, and the industries that rely on them.

Durability of high chrome grinding media balls

In the world of industrial grinding processes, the durability and efficiency of grinding media play a crucial role in determining overall productivity and cost-effectiveness. Among the various types of grinding media available, high chrome grinding media balls have gained significant popularity due to their exceptional wear resistance and long-lasting performance. This article delves into the durability of these remarkable grinding balls, exploring how they improve grinding efficiency, factors affecting their lifespan, and ways to maximize their performance.

How does grinding media surface roughness change over time?

Grinding media, such as the high-quality ball mill grinding media produced by NINGHU, play a crucial role in various industrial processes. The effectiveness of these grinding balls depends largely on their surface characteristics, particularly roughness. As grinding media are subjected to continuous wear and tear during operation, their surface morphology evolves, affecting their performance and lifespan. In this comprehensive guide, we'll explore the fascinating world of grinding media surface roughness and its transformation over time.

Troubleshooting Common Issues with Cylpebs in Grinding Circuits

The efficiency and efficacy of cylpebs grinding media have contributed significantly to their growing popularity within the industrial grinding sphere, as industries continuously seek methods to improve output and reduce operational costs. However, much like any other type of industrial equipment, cylpebs are not completely free from challenges that may reduce their overall effectiveness. Common issues such as uneven wear, improper mill loading, suboptimal operating conditions, or poor material compatibility can hinder performance and ultimately impact the quality of the final product. Addressing these problems proactively is crucial for maximizing results. The purpose of this manual is to provide practical guidance on identifying and solving these typical challenges, ensuring that grinding circuits operate more smoothly and efficiently while maintaining the full advantages that cylpebs grinding media can deliver in diverse industrial applications.

How Cylpebs Reduce Energy Consumption in Grinding Mills

.webp)

When it comes to industrial grinding, saving energy and achieving maximum efficiency are always among the highest priorities for manufacturers and plant operators. Rising energy costs and increasing environmental concerns have driven the industry to explore innovative technologies that can deliver measurable improvements in performance while also reducing operational expenses. In this context, cylpebs grinding media have emerged as a true game-changer, offering a combination of superior grinding efficiency and reduced energy consumption compared to traditional grinding balls. Their unique cylindrical geometry provides a larger contact surface, enhancing particle breakage efficiency and ensuring more uniform size distribution. Beyond technical performance, cylpebs are also considered an eco-friendly and economical substitute for conventional media, helping mills lower carbon footprints and extend equipment lifespan. This article explores their role in modern grinding operations, emphasizing their contribution to sustainable and cost-effective energy reduction strategies.

Where are high chrome grinding balls used in mining?

Because of its exceptional wear resistance and longevity in harsh conditions, high chrome grinding balls are indispensable in many mining operations. Various phases of mineral processing make use of these specialised grinding media, beginning with ore extraction and ending with refinement. This detailed manual will cover all the many uses of high chrome grinding balls, not just in mining but in many other fields as well.