Understanding Hardness in High Chrome Steel Grinding Media

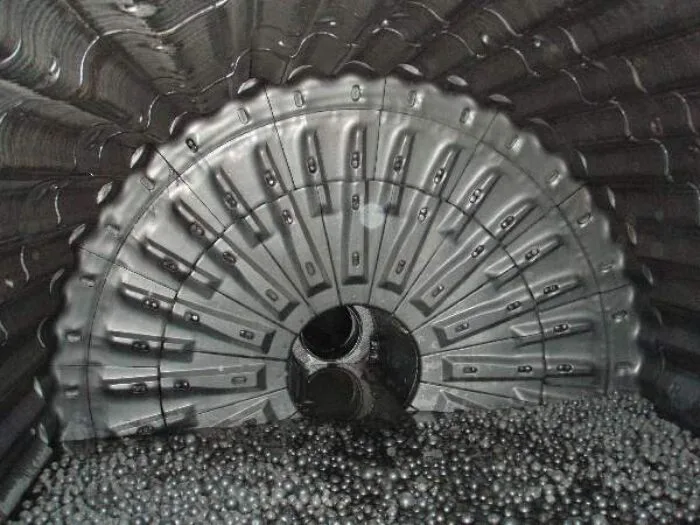

Hardness is a fundamental property that directly impacts the performance and longevity of grinding media. For high chrome steel grinding balls, hardness is particularly important as it determines their ability to withstand the rigorous demands of grinding operations. These balls are designed to endure repeated impacts, abrasion, and compressive forces while maintaining their shape and integrity.

The hardness of high chrome steel grinding media is influenced by several factors, including the chemical composition of the alloy, heat treatment processes, and manufacturing techniques. The high chromium content, typically ranging from 10% to 30%, contributes significantly to the hardness and wear resistance of these grinding balls.

Methods for Measuring Hardness in Grinding Media Balls

Several standardized methods are employed to measure the hardness of high chrome steel grinding media balls. These techniques provide quantitative data that allows manufacturers and users to assess and compare the hardness of different grinding media products. Let's explore some of the most common hardness measurement methods:

Rockwell Hardness Test

The Rockwell hardness test is a widely used method for measuring the hardness of metallic materials, including high chrome steel grinding media balls. This test involves applying a predetermined force to the surface of the ball using a diamond cone indenter or a hardened steel ball. The depth of the resulting indentation is measured, and the hardness value is calculated based on this measurement.

For high chrome steel grinding media, the Rockwell C scale (HRC) is typically used. This scale is suitable for measuring hard materials and provides a range of values from 20 to 70 HRC. Higher HRC values indicate greater hardness, with most high chrome steel grinding balls falling within the range of 60 to 65 HRC.

Vickers Hardness Test

The Vickers hardness test is another popular method for measuring the hardness of grinding media balls. This test utilizes a diamond pyramid indenter that is pressed into the surface of the ball with a specific force. The resulting indentation is then measured diagonally, and the hardness value is calculated based on the indentation size and the applied force.

The Vickers hardness test offers high precision and is suitable for measuring a wide range of materials, including high chrome steel. The hardness values are typically expressed in HV (Hardness Vickers) units, with higher values indicating greater hardness. High chrome steel grinding media balls often exhibit Vickers hardness values ranging from 600 to 900 HV.

Brinell Hardness Test

The Brinell hardness test is a method that involves pressing a hardened steel ball into the surface of the material being tested. For high chrome steel grinding media balls, a tungsten carbide ball is often used as the indenter due to the hardness of the material being tested. The diameter of the resulting indentation is measured, and the Brinell hardness number (BHN) is calculated based on the applied force and the indentation size.

While the Brinell test is less commonly used for high chrome steel grinding media compared to Rockwell or Vickers tests, it can still provide valuable information about the material's hardness. The Brinell hardness values for high chrome steel grinding balls typically range from 500 to 700 BHN.

Importance of Hardness Measurement in Grinding Media Selection

Accurate hardness measurement is essential for several reasons when it comes to high chrome steel grinding media balls:

1. Performance Prediction: Hardness values help predict the performance and wear resistance of grinding media in specific applications. This information is crucial for selecting the most suitable grinding media for a particular grinding process.

2. Quality Control: Manufacturers use hardness measurements as part of their quality control processes to ensure consistency and adherence to specifications. This helps maintain the reliability and performance of their grinding media products.

3. Comparative Analysis: Hardness measurements allow users to compare different grinding media options objectively. This facilitates informed decision-making when choosing between various products or suppliers.

4. Optimization of Grinding Processes: Understanding the hardness of grinding media helps in optimizing grinding parameters, such as mill speed and ball charge, to achieve the desired grinding efficiency and product quality.

5. Wear Rate Estimation: Hardness values can be used to estimate the wear rate of grinding media balls, enabling better planning for media replacement and maintenance schedules.

By utilizing standardized hardness measurement techniques, manufacturers and users of high chrome steel grinding media balls can ensure that they are working with products that meet the required specifications and performance standards. This, in turn, contributes to improved grinding efficiency, reduced downtime, and optimized operational costs in various industrial applications.

Conclusion

The measurement of hardness in high chrome steel grinding media balls is a critical aspect of quality control and performance evaluation in the grinding industry. Through standardized testing methods such as Rockwell, Vickers, and Brinell hardness tests, manufacturers and users can accurately assess and compare the hardness of different grinding media products. This knowledge is invaluable for selecting the most suitable grinding media for specific applications, optimizing grinding processes, and ensuring consistent performance in industrial grinding operations.

As technology continues to advance, we can expect further refinements in hardness measurement techniques and the development of even more durable and efficient grinding media solutions. For those seeking high-quality high chrome steel grinding media balls with superior hardness and wear resistance, NINGHU offers a range of products tailored to various industrial needs. To learn more about our grinding media solutions and how they can benefit your operations, please contact us at sales@da-yang.com and sunny@da-yang.com.