Superior Wear Resistance and Longevity

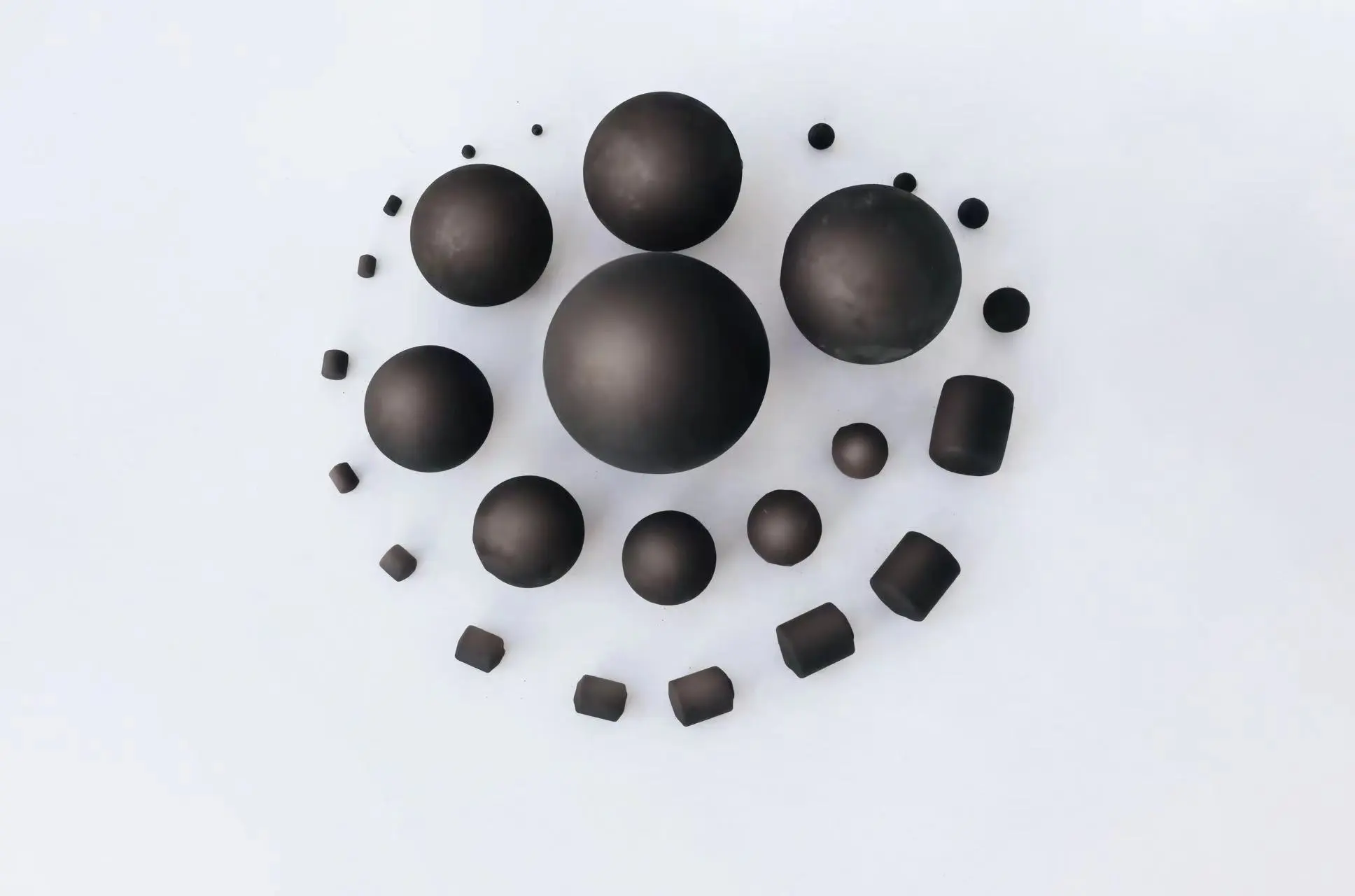

One of the most significant advantages of high chrome steel grinding media balls is their exceptional wear resistance. The high chromium content in these balls, typically ranging from 10% to 30%, contributes to the formation of a hard, protective layer on the surface. This layer, known as chromium carbide, provides remarkable resistance against abrasion and impact, resulting in a slower wear rate compared to other types of grinding media.

High chrome steel grinding media balls are renowned for their superior wear resistance, which is a crucial factor in prolonging their service life. The high carbon and chromium content in these balls enhances their hardness, allowing them to withstand significant impact and abrasion during grinding processes. This durability translates into fewer replacements, reducing downtime and maintenance costs for industrial operations. By minimizing wear, these grinding media balls not only maintain their shape and performance over extended periods but also contribute to more consistent grinding results. As a result, industries benefit from increased productivity and reduced operational interruptions, making high chrome steel balls a preferred choice.

The enhanced durability of high chrome steel grinding media balls translates to longer operational life. This longevity brings about several benefits:

- Reduced frequency of media replacement, leading to lower maintenance costs

- Decreased downtime for grinding equipment, improving overall productivity

- Consistent grinding performance over extended periods

- Lower risk of contamination in the final product due to reduced media wear

These factors combine to make high chrome steel grinding media balls a cost-effective solution for industries requiring continuous, high-performance grinding operations.

Enhanced Grinding Efficiency and Product Quality

The design and material composition of high chrome steel grinding media balls significantly enhance grinding efficiency and product quality. Their hardened surface minimizes energy loss during grinding, allowing for smoother and more effective material processing. This efficiency translates into faster production rates, as the balls effectively break down materials without excessive energy consumption. Furthermore, the uniformity of the balls ensures consistent particle size distribution, which is essential for achieving high-quality end products. By optimizing the grinding process, these media balls help manufacturers meet stringent quality standards while maximizing output, ultimately leading to greater customer satisfaction and competitive advantage in the market.

High chrome steel grinding media balls offer superior grinding efficiency compared to many alternative options. This improved efficiency stems from several factors:

- Higher hardness: The chromium carbide layer provides exceptional hardness, allowing for more effective particle size reduction

- Optimal sphericity: High-quality manufacturing processes ensure that these balls maintain a near-perfect spherical shape, promoting uniform grinding action

- Density advantage: The high density of chrome steel contributes to increased impact energy during the grinding process

The combination of these characteristics results in more efficient grinding, allowing for:

- Faster processing times

- Reduced energy consumption

- More uniform particle size distribution in the final product

Furthermore, the consistent wear pattern of high chrome steel grinding media balls helps maintain a stable grinding environment throughout their operational life. This stability contributes to improved product quality and consistency, which is crucial in industries such as cement production, mineral processing, and ceramics manufacturing.

Versatility and Adaptability to Various Applications

High chrome steel grinding media balls exhibit remarkable versatility, making them suitable for a wide range of applications across different industries. Their robust properties allow them to perform effectively in various environments, whether in mineral processing, cement production, or even in chemical applications. This adaptability means that companies can use the same type of grinding media for multiple processes, simplifying inventory management and reducing costs. Additionally, the ability to customize the size and composition of these balls allows manufacturers to tailor their solutions to specific operational requirements, ensuring optimal performance in each unique application. This flexibility is key to meeting diverse industry needs efficiently.

High chrome steel grinding media balls demonstrate remarkable versatility, making them suitable for a wide range of applications across different industries. Their adaptability stems from several key features:

- Corrosion resistance: The high chromium content provides excellent resistance against corrosive environments, allowing these balls to be used in diverse chemical conditions

- Temperature stability: High chrome steel maintains its properties across a wide temperature range, making it suitable for both wet and dry grinding processes

- Customizable properties: Manufacturers can adjust the chromium content and heat treatment processes to tailor the balls' properties for specific applications

This versatility allows high chrome steel grinding media balls to be effectively utilized in various industries, including:

- Cement and building materials production

- Mining and mineral processing

- Power generation (coal grinding)

- Ceramic and refractory materials manufacturing

- Chemical processing

- Pigment production

The adaptability of high chrome steel grinding media balls enables companies to streamline their grinding media inventory, potentially reducing costs associated with maintaining multiple types of grinding media for different applications.

Conclusion

High chrome steel grinding media balls offer numerous advantages over other types of grinding media. Their superior wear resistance, enhanced grinding efficiency, and versatility make them an excellent choice for a wide range of industrial applications. By selecting high chrome steel grinding media balls, companies can improve their grinding processes' efficiency, reduce operational costs, and enhance product quality.

For those interested in exploring high-quality high chrome steel grinding media balls and other wear-resistant materials, NINGHU offers a comprehensive range of products backed by over thirty years of production experience. To learn more about their offerings and how they can benefit your specific application, contact them at sales@da-yang.com and sunny@da-yang.com.