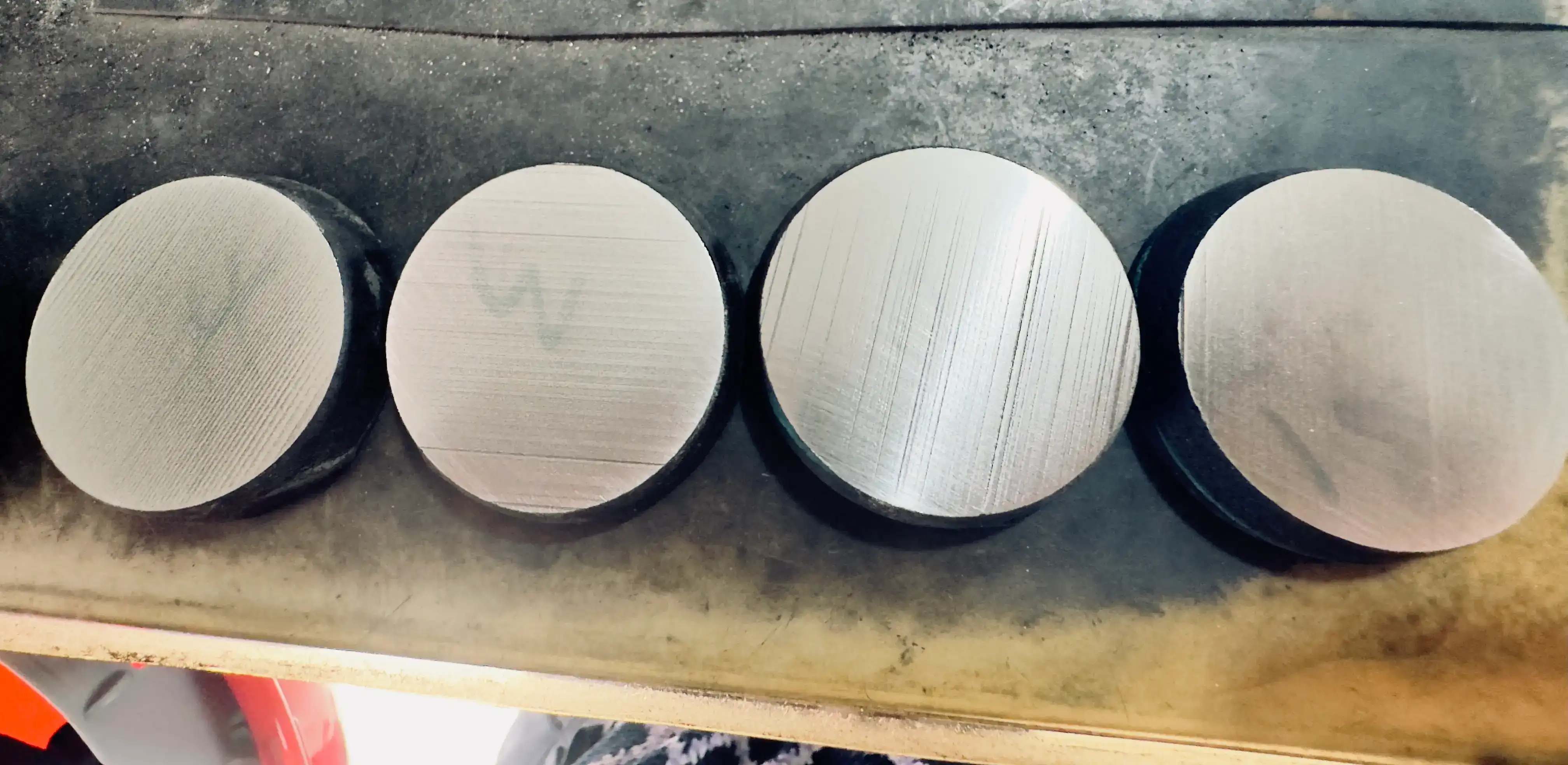

Composition and Properties of High Chrome Steel Grinding Media Balls

High chrome steel grinding media balls are crafted from a unique alloy that combines the strength of steel with the exceptional wear resistance of chromium. Typically, these balls contain between 10% to 30% chromium content, with the most common compositions falling in the range of 15% to 28%. This high chromium content is the key factor that sets these grinding media apart from other types.

The addition of chromium to the steel alloy imparts several advantageous properties to the grinding balls:

- Enhanced hardness: The chromium content significantly increases the hardness of the balls, allowing them to maintain their shape and size even under extreme grinding conditions. This exceptional hardness is crucial for ensuring that the grinding media can withstand the forces exerted during high-energy milling processes, thereby improving efficiency and performance.

- Superior wear resistance: The formation of a protective chromium oxide layer on the surface of the balls helps to prevent excessive wear and extends their operational lifespan. This protective layer acts as a barrier against abrasive materials, ensuring that the balls maintain their integrity over prolonged usage periods, which is vital for reducing replacement costs and minimizing downtime in industrial operations.

- Corrosion resistance: High chrome content provides excellent resistance against chemical corrosion, making these balls suitable for use in aggressive grinding environments. This property allows them to endure exposure to various harsh chemicals and acidic substances without degrading, further enhancing their reliability in diverse applications.

- Impact toughness: Despite their high hardness, these balls maintain a good level of toughness, reducing the risk of breakage during operation. This combination of hardness and toughness ensures that the grinding media can effectively handle the impact forces involved in crushing and grinding materials without fracturing, leading to consistent performance and longevity in demanding conditions.

The manufacturing process of high chrome steel grinding media balls involves precise control of the alloy composition, heat treatment, and quality assurance measures to ensure consistent performance across batches. This meticulous production approach results in grinding media that can withstand the demands of intensive industrial applications.

Applications and Industries Utilizing High Chrome Steel Grinding Media Balls

High chrome steel grinding media balls find widespread use across various industries due to their exceptional performance characteristics. Some of the primary sectors that rely on these grinding media include:

- Mining and mineral processing: In ore beneficiation plants, high chrome steel balls are used in ball mills to grind ores into fine particles, facilitating the extraction of valuable minerals.

- Cement production: The cement industry employs these grinding media in cement mills to achieve the desired fineness of cement clinker and other raw materials.

- Power generation: Coal-fired power plants use high chrome steel balls in pulverizers to grind coal into a fine powder for efficient combustion.

- Ceramic and glass manufacturing: These industries utilize the balls for grinding and mixing raw materials to achieve the desired particle size distribution.

- Chemical processing: Various chemical processes benefit from the use of high chrome steel grinding media for size reduction and homogenization of materials.

The versatility of high chrome steel grinding media balls allows them to be used in both wet and dry grinding applications, making them suitable for a wide range of industrial processes. Their ability to maintain performance under diverse operating conditions has contributed to their popularity across these sectors.

Advantages and Considerations of Using High Chrome Steel Grinding Media Balls

The adoption of high chrome steel grinding media balls offers several significant advantages to industrial operations:

- Extended service life: The superior wear resistance of these balls translates to longer operational lifespans, reducing the frequency of media replacement and associated downtime.

- Improved grinding efficiency: The hardness and durability of high chrome steel balls allow for more effective grinding, potentially increasing throughput and reducing energy consumption.

- Consistent performance: The uniform composition and properties of these grinding media ensure consistent grinding results over time, contributing to product quality and process stability.

- Reduced contamination: The high wear resistance of chrome steel balls minimizes the introduction of iron contamination into the ground material, which is crucial in certain applications.

- Cost-effectiveness: While the initial cost of high chrome steel grinding media may be higher than that of lower-grade alternatives, their longer lifespan and improved performance often result in lower overall operational costs.

However, when considering the use of high chrome steel grinding media balls, it's important to take into account certain factors:

- Initial investment: The upfront cost of high chrome steel balls is typically higher than that of standard steel or cast iron grinding media.

- Matching to application: Selecting the appropriate chrome content and ball size is crucial for optimizing performance in specific grinding applications.

- Environmental considerations: Proper disposal or recycling of worn-out grinding media should be factored into the operational plan to minimize environmental impact.

By carefully evaluating these aspects, industries can make informed decisions about implementing high chrome steel grinding media balls in their processes, potentially reaping significant benefits in terms of efficiency, product quality, and long-term cost savings.

In conclusion, high chrome steel grinding media balls represent a pinnacle of grinding technology, offering unparalleled wear resistance, durability, and performance across a wide range of industrial applications. Their unique composition and properties make them an invaluable tool in the quest for efficient and effective material processing. As industries continue to seek ways to optimize their operations and reduce costs, the role of high chrome steel grinding media balls is likely to become even more prominent. For those interested in learning more about these exceptional grinding media or exploring their potential applications, please don't hesitate to reach out to us at sales@da-yang.com and sunny@da-yang.com for expert guidance and product information.