What Are High-Chrome Grinding Balls?

In industries where grinding operations are key processes, the choice of grinding media significantly impacts efficiency, operational costs, and product quality. High-chrome grinding balls have gained popularity due to their excellent wear resistance, high density, and ability to maintain shape under harsh conditions. In this article, we delve into the specifics of high-chrome grinding balls, exploring their composition, properties, applications, and advantages over other types of grinding media.

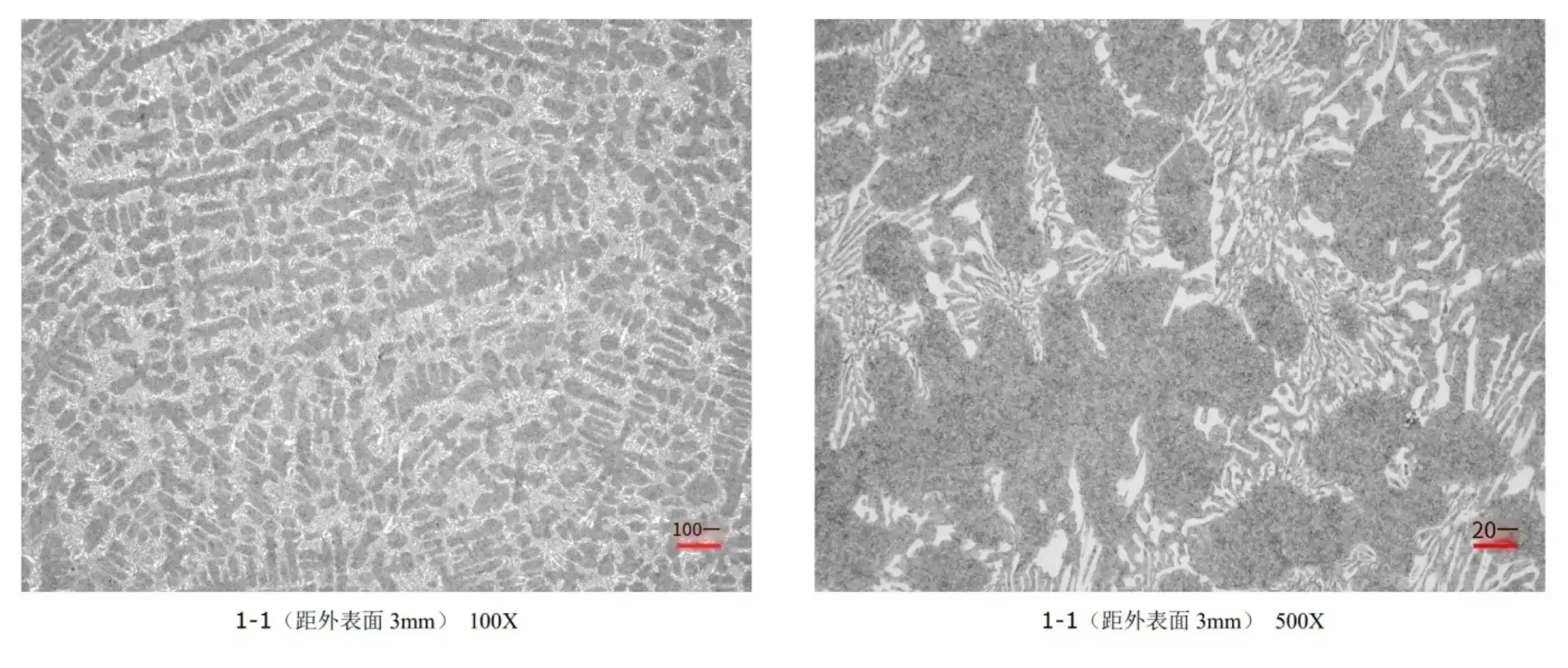

How does the microstructure of grinding balls influence their performance?

Grinding balls are crucial components used in various industrial applications, especially in the mining and mineral processing industries. Their effectiveness in grinding operations depends significantly on their microstructure. The microstructure, which includes aspects like the chemical composition, hardness, and internal defects of the grinding balls, plays a vital role in determining their performance and durability.

The Pros and Cons of High Chrome Grinding Balls

In the world of industrial grinding, high chrome grinding balls have emerged as a popular choice for various applications. These robust spheres, crafted with a significant chromium content, offer unique advantages and potential drawbacks that merit careful consideration. This comprehensive guide delves into the intricacies of the product, exploring their benefits and limitations to help you make an informed decision for your grinding needs.

What are the maintenance requirements for using high chrome steel grinding media balls?

.webp)

High chrome steel grinding media balls are essential components in various industrial grinding processes. These durable and efficient grinding tools require proper maintenance to ensure optimal performance and longevity. In this comprehensive guide, we'll explore the crucial maintenance requirements for high chrome steel grinding media balls, helping you maximize their effectiveness and extend their lifespan.

Maximizing Performance with High Chrome Grinding Balls

In the world of industrial grinding, the choice of grinding media can significantly impact the efficiency and effectiveness of your operation. Among the various options available, high chrome grinding balls have emerged as a top performer, offering exceptional durability and grinding efficiency. This article delves into the world of high chrome grinding media, exploring how to maximize their performance and why they're becoming the go-to choice for many industries.

How to measure grinding ball impact resistance?

In the world of mining and mineral processing, grinding balls play a crucial role in reducing ore particles to the desired size for efficient extraction. The impact resistance of these balls is a critical factor in grinding balls mining performance and longevity. This article delves into the methods used to measure grinding ball impact resistance, providing valuable insights for professionals in the mining industry.

What innovations are there in the manufacturing of grinding balls?

Grinding balls are essential components used in various industries for reducing the size of particles and facilitating finer grinding of minerals, cement, and other materials. The manufacturing processes involved in producing these balls have seen significant innovations over the years, driven by advancements in materials science, manufacturing technologies, and the demand for higher performance and durability. Explore the latest innovations in the manufacturing of grinding balls, focusing on materials, production techniques, and environmental considerations.

Grinding with High Chrome Balls: Tips and Tricks

In the world of industrial grinding, high chrome grinding balls have become an indispensable tool for achieving optimal results. These robust and durable components play a crucial role in various industries, including cement production, mining, and power generation. This article will delve into the intricacies of using high chrome grinding balls effectively, providing you with valuable tips and tricks to enhance your grinding processes.

How do high chrome steel grinding media balls contribute to cost-effectiveness?

In industries such as cement, mining, and thermal power generation, the efficiency and longevity of grinding media can make a significant impact on operational costs. High chrome steel grinding media balls are a key player in reducing these costs while boosting performance. In this article, we'll explore how these specialized balls contribute to cost-effectiveness, why they're an essential component in various industrial applications, and how they can save businesses money in the long run.

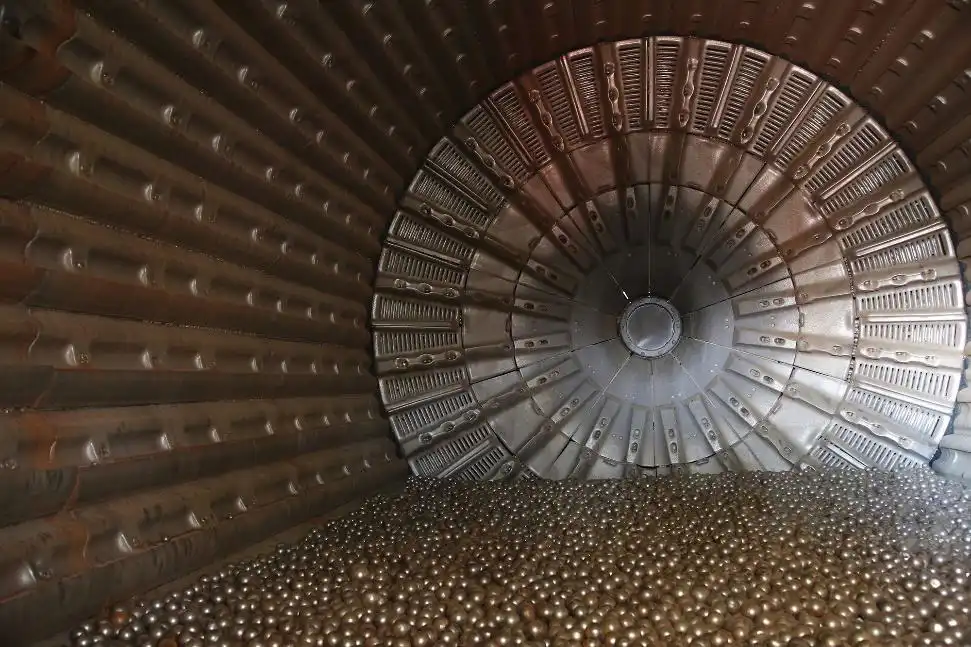

Applications of High Chrome Grinding Balls in Mining

In the dynamic world of mining, efficiency and durability are paramount. One crucial component that plays a significant role in mineral processing is grinding media, particularly high chrome grinding balls. These robust spheres have revolutionized the mining industry, offering unparalleled performance in crushing and grinding operations. This article delves into the applications of high chrome grinding balls in mining, exploring their role, advantages, and industry trends.

What factors contribute to grinding ball corrosion?

Grinding balls are essential components in various industrial processes, particularly in mining operations. These robust spheres play a crucial role in reducing the size of materials through impact and abrasion. However, the harsh environments in which grinding balls mining operate can lead to significant corrosion issues, impacting their performance and lifespan. Understanding the factors that contribute to grinding ball corrosion is vital for optimizing mill operations and reducing maintenance costs.

How does forging differ for grinding media?

To reduce raw materials to tiny particles, grinding media is an important tool in the mineral processing and materials science industries. Although there are other options for high chrome grinding media, forged grinding balls' distinctive qualities and production method have contributed to their meteoric rise in popularity. Learn more about the differences between forging grinding media and why it affects your milling processes with this in-depth tutorial.