Why Are Grinding Cylpebs Gaining Popularity?

Do Grinding Balls Require Specialized Handling and Storage?

What are the advantages of using steel grinding balls?

How does grinding media affect the grinding process?

In the world of industrial processing, grinding media plays a pivotal role in shaping the efficiency and effectiveness of grinding operations. Whether you're involved in cement production, metallurgical mining, or thermal power generation, understanding the impact of the product on the grinding process is crucial for optimizing your operations. Let's delve into the intricacies of how these seemingly simple components can make a world of difference in your grinding results.

What industries commonly use chromium casting grinding balls?

Chromium casting grinding balls have become an indispensable component in various industrial processes, offering exceptional wear resistance and durability. These high-performance grinding media play a crucial role in enhancing efficiency and productivity across multiple sectors. In this comprehensive guide, we'll explore the diverse industries that rely on chromium casting grinding balls and delve into their unique applications.

How does high chrome grinding media compare to low chrome media?

In the world of industrial grinding, the choice of grinding media plays a crucial role in determining the efficiency and effectiveness of the grinding process. Among the various options available, high chrome grinding media and low chrome grinding media are two popular choices. This article delves into the comparison between these two types of grinding media, exploring their characteristics, advantages, and applications.

How do grinding balls affect the grinding process in mining?

How does the hardness of grinding balls impact their performance in ball mills?

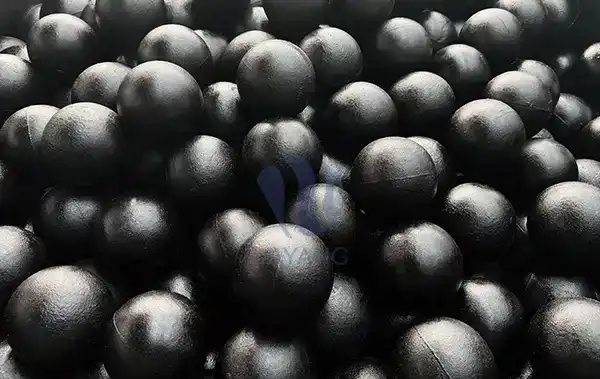

The hardness of Grinding Balls for Ball Mill is crucial for their performance in ball mills, impacting efficiency and effectiveness in grinding operations. In industries like mining, cement manufacturing, and metallurgy, the hardness affects wear resistance, grinding efficiency, and lifespan. Harder balls offer better wear resistance, maintaining their shape and size longer for consistent performance. However, the optimal hardness depends on the material being processed. Softer materials require less hard balls to avoid over-grinding, while harder materials need higher hardness for effective size reduction. Balancing hardness is key to optimizing performance and reducing costs.

What is the grinding media in cement plant?

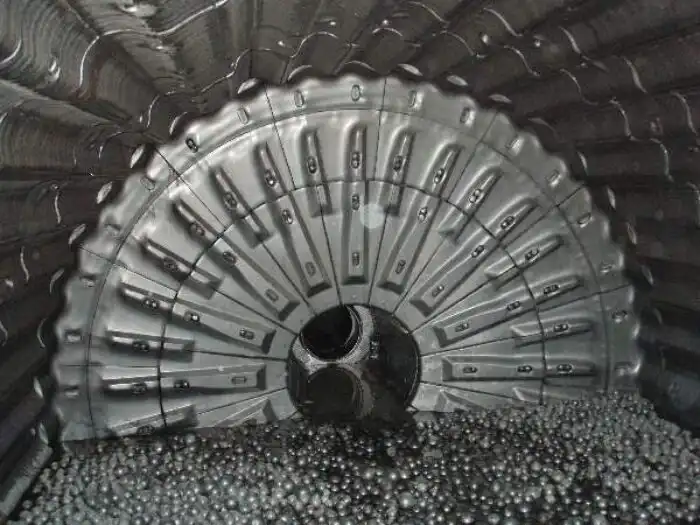

Grinding media in cement plants play a crucial role in the production process, with ball mill grinding media being the most common type. These are typically spherical or cylindrical objects used inside ball mills to crush and grind raw materials into fine particles. Ball mill grinding media are essential components that significantly impact the efficiency and quality of cement production. They come in various sizes and materials, each designed to optimize the grinding process for different stages of cement manufacturing. The choice of grinding media depends on factors such as the hardness of the material being ground, the desired fineness of the final product, and the specific requirements of the cement plant's operations.

Maximizing Efficiency with Steel Grinding Media

In the world of industrial grinding, efficiency is paramount. Steel grinding media have emerged as a cornerstone of productivity, offering unparalleled performance in various applications. This article delves into the innovative uses, cost impacts, and maintenance tips for steel grinding media, providing valuable insights for industries seeking to optimize their grinding processes.

Top Benefits of High-Quality Grinding Media

In the world of industrial grinding processes, the quality of your grinding media can make all the difference. Grinding media, specifically high-quality options, offer numerous benefits that can significantly impact your operations. This article explores the advantages of investing in superior grinding media and how it can enhance your grinding processes.

How does grinding ball hardness impact mill efficiency?

Grinding balls play a crucial role in mineral processing, and their hardness is a key factor that significantly influences mill efficiency. Understanding the relationship between grinding ball hardness and mill performance is essential for optimizing mineral liberation and maximizing productivity in grinding balls mining operations. This article delves into the intricacies of grinding ball hardness and its impact on mill efficiency, providing valuable insights for industry professionals.