What are the advantages of using wear-resistant casting iron steel hammers?

In the realm of construction, mining, and various industrial applications, the choice of materials for tools and machinery components plays a pivotal role in determining efficiency, durability, and cost-effectiveness. Among the array of options available, wear-resistant casting iron steel hammers stand out for their remarkable advantages. In this article, I will delve into the advantages of these hammers, exploring the unique properties of cast iron and steel, and how they combine to create robust and effective tools for a multitude of purposes.

Impact of Composition on Grinding Ball Performance

Why Should You Switch to Grinding Cylpebs?

Grinding cylpebs are gaining popularity in the grinding media market, but what makes them stand out? Why should you consider switching to grinding cylpebs for your grinding operations? In this blog post, we'll explore the benefits of using grinding cylpebs, their advantages over other types of grinding media, and why they could be the right choice for your grinding needs.

How Can Grinding Balls Improve Efficiency in Mineral Processing?

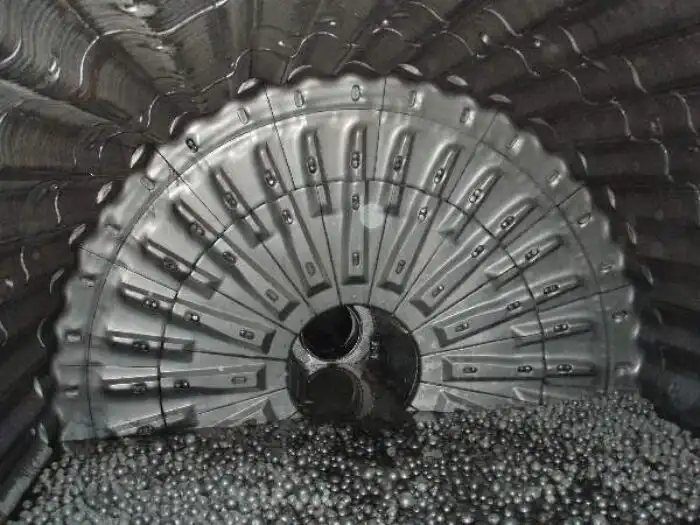

How Ball Mill Works?

A ball mill balls works by turning a chamber with steel crushing balls, making the balls fall once more into the chamber and onto the material to be ground. The pivot is as a rule between 4 to 20 cycles each moment, contingent on the measurement of the mill. The bigger the distance across, the more slow the turn. On the off chance that the fringe speed of the mill is excessively perfect, it starts to carry on like a rotator and the balls don't fall back yet remain on the border of the mill.

How long do grinding balls typically last in a mill?

Grinding balls are a crucial component in various milling processes, providing the necessary force to break down materials into fine powders. Their lifespan is a key factor in the efficiency and cost-effectiveness of milling operations, influencing downtime, maintenance schedules, and overall productivity.

How do I properly maintain and clean grinding media?

Grinding media play a crucial role in various industries, from cement production to metallurgical mining. These small but mighty components are essential for efficient material processing and require proper maintenance and cleaning to ensure optimal performance and longevity. In this comprehensive guide, we'll explore the best practices for maintaining and cleaning the product, helping you maximize their efficiency and extend their lifespan.

Are there any environmental concerns associated with chromium casting grinding balls?

In the world of industrial grinding and milling, chromium casting grinding balls have become an indispensable tool. These robust spheres play a crucial role in various industries, including cement production, metallurgy, and mining. However, as our global focus shifts towards environmental sustainability, it's essential to examine the potential ecological impacts of these widely used components. This article delves into the environmental considerations surrounding chromium casting grinding balls, exploring their production, use, and disposal.

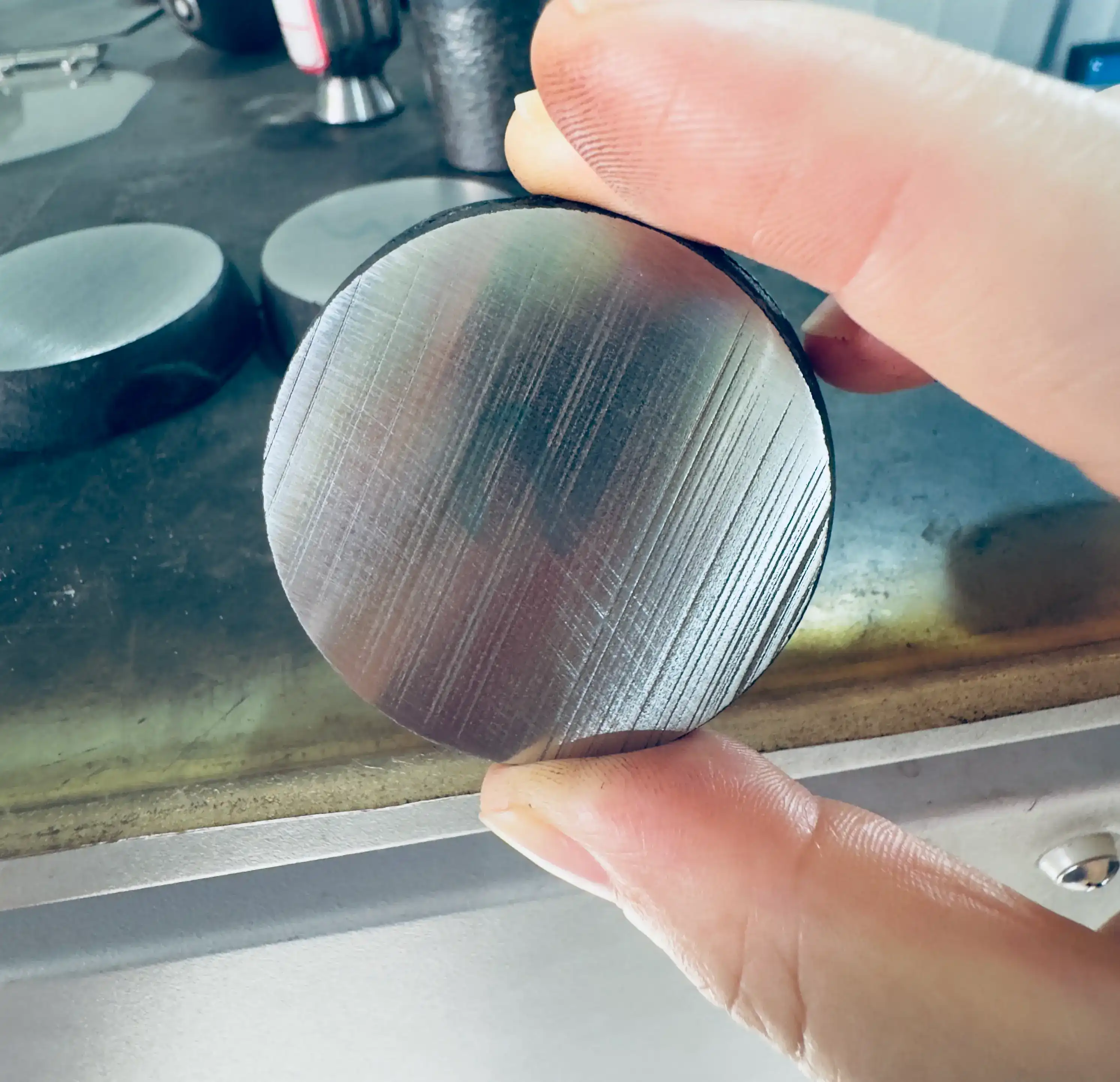

How does the hardness of grinding balls influence their performance?

The hardness of Grinding Balls for Mining is crucial for performance and efficiency in mining operations. It impacts wear resistance, grinding efficiency, and longevity. Harder balls typically offer better wear resistance, maintaining shape and size longer, resulting in consistent performance and fewer replacements. However, excessive hardness may increase energy consumption and damage mill linings. Softer balls wear faster but can be more energy-efficient and gentler on mill components. The optimal hardness depends on factors like ore type and mill specifications, ensuring a balance that maximizes efficiency and minimizes operational costs.

How do ceramic grinding balls compare to steel balls in ball mills?

Selecting the right Grinding Balls for Ball Mill—ceramic or steel balls—can significantly impact milling efficiency. Ceramic grinding balls offer high hardness, wear resistance, and excellent performance in fine grinding, maintaining their spherical shape longer. Steel balls, with superior impact strength, are ideal for coarse grinding. The choice between the two depends on factors like the material being ground, desired particle size, and milling requirements. Understanding these key differences is crucial for optimizing ball mill performance and achieving desired results. This comparison helps in making an informed decision for specific milling applications.

What is a grinding media?

Grinding media, particularly ball mill grinding media, are essential components in various industrial processes. These specialized materials play a crucial role in reducing particle sizes and achieving desired material properties. Ball mill grinding media typically consist of spherical or cylindrical objects made from durable materials designed to withstand the rigorous grinding process. These media are placed inside rotating mills, where they collide with the material being processed, effectively breaking it down into smaller particles. The efficiency and effectiveness of ball mill grinding media are determined by factors such as their size, shape, density, and material composition. Industries ranging from mining and cement manufacturing to power generation and chemical production rely heavily on ball mill grinding media to optimize their processes and produce high-quality end products.

Eco-Friendly Steel Grinding Media Solutions

In today's rapidly evolving industrial landscape, the pursuit of eco-friendly solutions has become paramount. The steel grinding media industry, a crucial component in various manufacturing processes, is no exception to this green revolution. This blog post delves into the innovative approaches and sustainable practices that are reshaping the production and use of steel grinding media, offering a glimpse into a more environmentally conscious future for industrial grinding operations.