What are the advantages of using chromium casting grinding cylpebs?

In the realm of material processing and grinding, the choice of grinding media plays a pivotal role in achieving optimal results. Chromium casting grinding cylpebs have emerged as a popular choice among industries for their unique properties and advantages. In this article, I will delve into the significance of grinding balls, the nature of cylpebs, and the advantages and disadvantages of ball mills, shedding light on why chromium casting grinding cylpebs are favored in various applications.

Key Properties of High-Quality Grinding Balls

What Factors Should You Consider When Choosing Grinding Cylpebs?

The selection of grinding cylpebs is significantly influenced by the material and hardness properties, as these factors directly impact the performance, wear resistance, and overall effectiveness of the grinding media. Understanding how material and hardness affect grinding cylpeb selection is crucial for optimizing the grinding process and achieving desired outcomes.

What Makes High-Quality Grinding Balls Stand Out?

How to Ball Mill Black Powder?

Black powder, otherwise called explosive, is an exemplary combination of potassium nitrate, charcoal, and sulfur. It's broadly utilized in firecrackers, ammo, and fireworks. Making dark powder requires cautious blending of fixings to guarantee a uniform piece consumes equally and dependably. One compelling strategy for blending these parts is utilizing a Ball Mill Balls.

What materials are grinding balls made of?

Grinding balls are essential components in various industrial processes, particularly in mining, cement production, and other material processing industries. These spherical objects play a crucial role in grinding or milling materials into finer particles, enhancing the efficiency of the processes they are part of. The materials used to manufacture grinding balls significantly impact their performance, durability, and cost-effectiveness.

How can you optimize the performance of chromium casting grinding balls in milling processes?

In the world of industrial milling, chromium casting grinding balls play a pivotal role in enhancing efficiency and productivity. These robust grinding media are essential components in various industries, including cement production, metallurgy, and mining. To achieve optimal results, it's crucial to understand how to maximize the performance of these high-quality grinding balls. This article delves into the intricacies of optimizing chromium casting grinding balls for superior milling outcomes.

What are the advantages of using high-quality grinding media?

In the world of industrial processing, the importance of high-quality grinding media cannot be overstated. These unsung heroes play a crucial role in various industries, from cement production to mineral processing. But what exactly makes high-quality product so advantageous? Let's delve into the world of grinding balls and cylpebs to uncover their benefits and why they're essential for efficient and cost-effective operations.

What factors influence the performance of high chrome grinding media?

High chrome grinding media play a crucial role in various industrial processes, particularly in mineral processing and cement production. These durable and efficient grinding tools are designed to withstand the harsh conditions of ball mills and other grinding equipment. Understanding the factors that influence their performance is essential for optimizing grinding operations and achieving desired results. In this comprehensive guide, we'll explore the key elements that impact the effectiveness of high chrome grinding media.

What factors contribute to the wear resistance of grinding balls?

The wear resistance of Grinding Balls for Mining is crucial for their performance and longevity in mining operations. Key factors influencing this include material composition, manufacturing process, and heat treatment. High-quality alloys, such as high-chrome or low-chrome steel, enhance durability, while casting or forging techniques affect the microstructure and wear resistance. Heat treatments like quenching and tempering optimize hardness and toughness. Surface treatments, such as shot peening, can further improve wear resistance. Additionally, the size and shape of grinding balls impact impact force distribution, improving grinding efficiency and reducing operational costs.

How do you clean grinding balls for reuse in a ball mill?

.webp)

Cleaning Grinding Balls for Ball Mill for reuse is essential to maintain ball mill performance and longevity. Over time, grinding balls accumulate debris and wear particles that reduce efficiency. Effective cleaning methods include mechanical techniques like tumbling or vibration, high-pressure water jetting, and ultrasonic cleaning for smaller balls. The cleaning method depends on factors such as ball material, contamination level, and application. Regular cleaning extends the lifespan of grinding balls, ensures consistent grinding quality, reduces energy consumption, and improves overall mill efficiency, making it crucial for industries like mining, cement, and power generation.

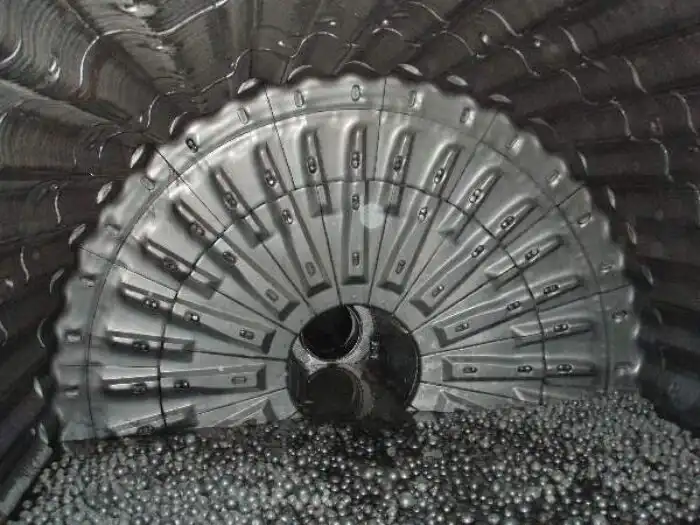

What are the different types of grinding media used in ball mills?

.webp)

Ball mill grinding media are vital for grinding, crushing, and pulverizing materials in industries like mining, cement, power generation, and metallurgy. The choice of grinding media impacts efficiency, energy consumption, and product quality. Common types include high chrome cast iron balls, low chrome cast steel balls, forged steel balls, and ceramic balls. High chrome balls offer wear resistance for cement and mineral processing, while low chrome balls balance hardness and toughness for various applications. Forged steel balls provide durability for heavy-duty operations, and ceramic balls are ideal for fine grinding or avoiding metal contamination in specialized processes.