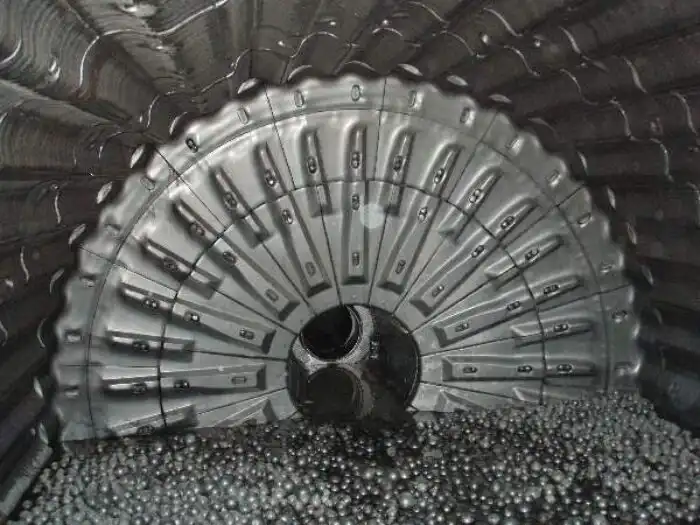

Chromium Casting Grinding Balls: Enhancing Efficiency in Industrial Grinding Processes

In the realm of industrial grinding, where efficiency and durability are paramount, chromium casting grinding balls have emerged as a game-changing solution. These high-performance grinding media are revolutionizing various industries, from cement production to mineral processing, by offering superior wear resistance and prolonged service life. This article delves into the world of chromium casting grinding balls, exploring their unique properties, applications, and the significant impact they're making on industrial grinding processes.

Can high chrome grinding media be recycled?

In the world of industrial grinding, high chrome grinding media play a crucial role in various sectors, including cement production, mining, and power generation. As sustainability becomes an increasingly important consideration in manufacturing processes, many industries are exploring ways to reduce waste and maximize resource efficiency. This raises an intriguing question: Can high chrome grinding media be recycled? Let's delve into this topic and explore the possibilities, challenges, and potential benefits of recycling these essential components.

Can grinding balls be recycled after use in mining operations?

Grinding Balls for Mining are essential in mining operations, especially for ore comminution. As sustainability becomes a focus, the recyclability of grinding balls is gaining attention. Yes, grinding balls can be recycled, offering benefits like resource conservation, reduced environmental impact, and cost savings. The recycling process involves collecting, sorting, melting, and recasting used balls to create new grinding balls or steel products, promoting a circular economy. However, recyclability depends on material composition, wear, and contamination. High-chrome balls, for example, may require specialized processes, and heavily worn or contaminated balls may need extra processing.

How does moisture content affect the performance of grinding balls in ball mills?

Moisture content is vital for the performance of Grinding Balls for Ball Mill. It affects particle size reduction, energy consumption, and mill efficiency. Excess moisture can cause particle agglomeration, reducing grinding efficiency and causing blockages, while insufficient moisture leads to increased dust and inefficient breakage. Optimizing moisture content is crucial for achieving the desired particle size distribution and consistent grinding performance. By controlling moisture levels, industries like mining, cement manufacturing, and power generation can improve ball mill productivity and prolong the lifespan of grinding balls.

How do you choose the right grinding media for ball mills?

Selecting the right Ball Mill Grinding Media is crucial for optimizing milling operations. The choice depends on factors like material being ground, desired particle size, and industry requirements. High-quality media, such as those from NINGHU, can improve performance, reduce energy consumption, and enhance product quality. Key considerations include hardness, density, size distribution, wear resistance, and chemical composition (e.g., chromium content), all of which affect suitability for various applications. Understanding these factors helps make an informed decision for your milling needs.

Boost Cement Efficiency with Grinding Media Balls

In the ever-evolving world of cement production, efficiency is paramount. One of the key components in achieving optimal cement quality and production rates is the use of grinding media balls. These unassuming spheres play a crucial role in the cement manufacturing process, significantly impacting the final product's quality and the overall efficiency of the operation. Let's delve into the world of cement grinding media balls and explore how they can boost your cement production efficiency.

Top Advantages of High Chrome Grinding Media for Industries

In the world of industrial grinding, the choice of grinding media can significantly impact the efficiency and cost-effectiveness of operations. High Chrome grinding media has emerged as a preferred solution for many industries due to its exceptional properties and performance. This article explores the top advantages of using chrome grinding media in various industrial applications, highlighting why it's becoming an increasingly popular choice for businesses aiming to optimize their grinding processes.

How to select grinding balls for specific ore types?

In the world of mineral processing, selecting the right grinding balls mining for your specific ore type is crucial for optimizing efficiency and productivity. Whether you're dealing with gold, copper, or other valuable minerals, understanding how to choose the appropriate grinding media can make a significant difference in your mining operations. This comprehensive guide will walk you through the key factors to consider when selecting grinding balls for various ore types.

Key Benefits of Using Cylpebs in Industrial Grinding Operations

.webp)

In the world of industrial grinding, efficiency and cost-effectiveness are paramount. As manufacturers continuously seek ways to optimize their processes, cylpebs grinding media has emerged as a game-changing solution. This innovative grinding media offers numerous advantages over traditional grinding balls, making it an increasingly popular choice across various industries. In this comprehensive guide, we'll explore the key benefits of using cylpebs in industrial grinding operations and why they're becoming the preferred choice for many manufacturers.

How does the density of grinding media impact the grinding process?

The density of the grinding media is an important factor in industrial grinding since it determines how efficient and successful the grinding process is. Understanding the influence of grinding media density may greatly improve your operations, whether you're engaged in cement manufacturing, mining, or any other business that depends on particle size reduction. How does the product's density affect different parts of the grinding process? Let's find out by diving into this subject.

Are Grinding Cylpebs Better Than Balls for Cement Mills?

In the world of cement production, the efficiency of cylpebs grinding media plays a crucial role in determining the quality and cost-effectiveness of the final product. As technology advances, manufacturers are constantly seeking innovative solutions to enhance their grinding processes. One such innovation that has gained attention in recent years is the use of cylpebs as an alternative to traditional grinding balls. This article delves into the comparison between cylpebs and balls, examining their performance, impact on cement quality, and economic implications.

How do composite grinding balls perform in mills?

Grinding media performance is a crucial factor that directly influences operational efficiency, production outcomes, and cost-effectiveness in the mineral processing and mining industries. Among the available options, grinding balls for mining play a vital role in crushing and refining ores during mill operations. In recent years, composite grinding balls have gained attention as an innovative and practical alternative to the more conventional steel or cast iron varieties. These advanced composites provide notable advantages, including longer service life, greater resistance to wear and breakage, and improved energy efficiency. As a result, they are increasingly being adopted as a viable replacement for traditional grinding media in demanding mining environments. This article examines the growing usefulness of composite grinding balls for mining, comparing their performance with conventional options and assessing their impact on mill lifespan, maintenance requirements, cost-effectiveness, and overall operational efficiency.