What are the advantages of using cylpebs as grinding media?

As someone deeply involved in the field of materials processing, I have always been intrigued by the various methods and tools used to achieve efficient grinding. Among these tools, grinding media play a crucial role in ensuring the desired particle size reduction and product quality. In this article, I will delve into the advantages of using cylpebs as grinding media, exploring their applications, benefits, and the factors influencing their efficiency.

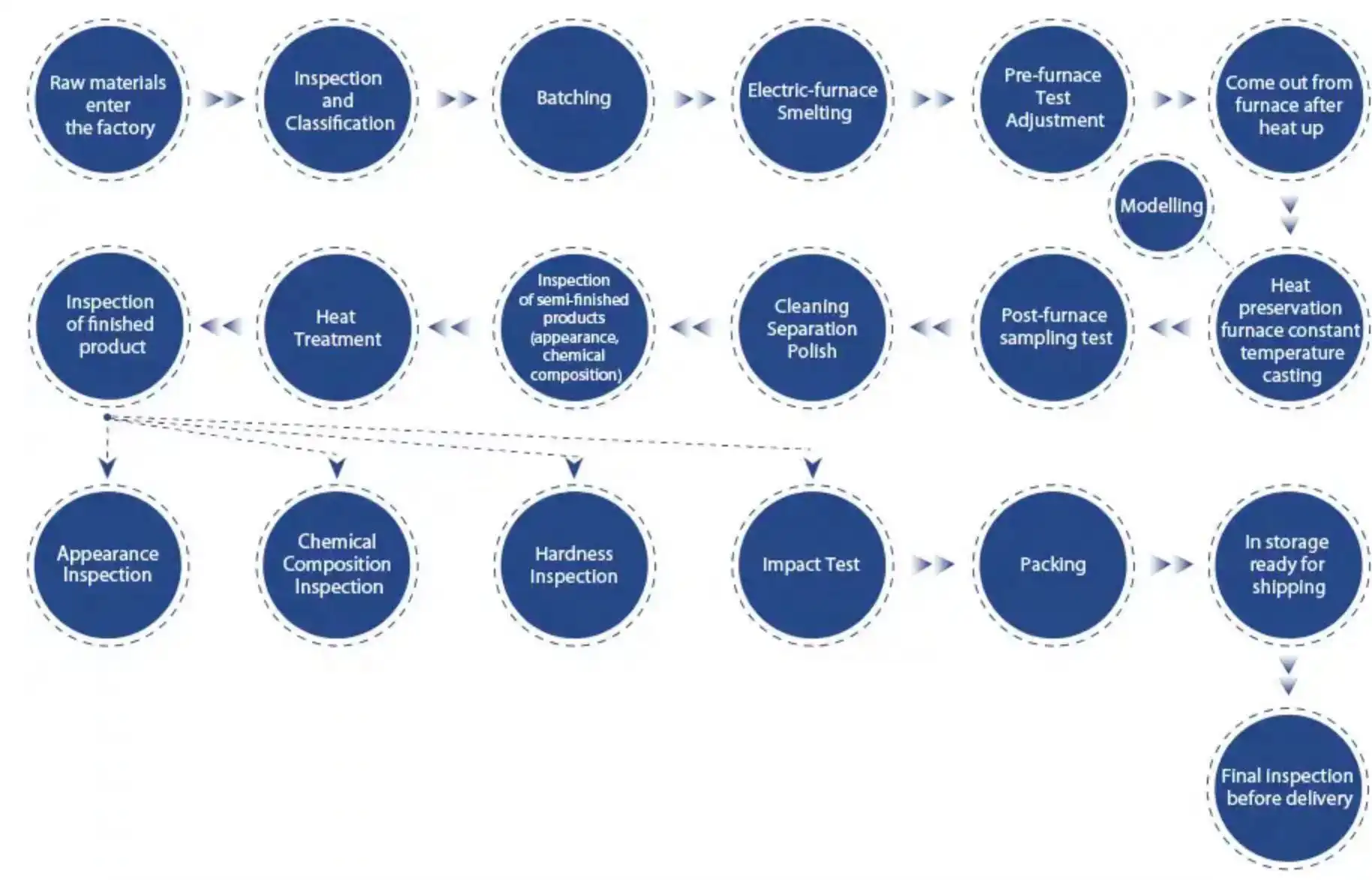

Understanding the Manufacturing Process of Grinding Balls

How Can Grinding Cylpebs Reduce Your Maintenance Costs?

Are Grinding Balls the Secret to Consistent Particle Size Reduction?

Are there environmentally friendly options for grinding balls?

Grinding balls are essential in various industrial processes, particularly in mining, cement manufacturing, and power plants. However, the production and use of traditional grinding balls raise environmental concerns due to their energy-intensive manufacturing processes and potential for pollution. In response to increasing environmental awareness, there has been a growing interest in finding sustainable alternatives.

7 Tips for Making the Most of Grinding Media

Grinding media plays a crucial role in various industries, from cement production to metallurgical mining. These robust tools are the unsung heroes of material processing, responsible for breaking down particles and creating finer, more uniform end products. Whether you're a seasoned professional or new to the world of grinding media, optimizing your use of these essential components can significantly improve your operations. In this article, we'll explore seven invaluable tips to help you maximize the efficiency and effectiveness of your product.

Chromium Casting Grinding Balls: Enhancing Efficiency in Industrial Grinding Processes

In the realm of industrial grinding, where efficiency and durability are paramount, chromium casting grinding balls have emerged as a game-changing solution. These high-performance grinding media are revolutionizing various industries, from cement production to mineral processing, by offering superior wear resistance and prolonged service life. This article delves into the world of chromium casting grinding balls, exploring their unique properties, applications, and the significant impact they're making on industrial grinding processes.

Choosing the Right High Chrome Grinding Media for Your Business

How does grinding ball charging impact mill throughput?

Grinding balls mining charging plays a crucial role in determining the efficiency and productivity of ball mills in various industries, including mining, cement production, and mineral processing. The proper selection and charging of grinding balls can significantly enhance mill throughput, leading to improved operational performance and cost-effectiveness. In this comprehensive guide, we'll explore the intricate relationship between grinding ball charging and mill throughput, providing valuable insights for optimizing your milling operations.

Cylpebs in Gold Ore Processing: Efficiency and Cost Analysis

In the realm of gold ore processing, the quest for enhanced efficiency and cost-effectiveness remains an ongoing challenge. As mining companies strive to optimize their operations, the choice of grinding media plays a crucial role in determining both the productivity and economic viability of their processes. Among the various options available, cylpebs grinding media has emerged as a compelling choice, offering unique advantages in gold ore processing applications.

How can you improve the life of grinding media in a ball mill?

Ball mills rely heavily on grinding media to reduce material size, a process that plays a critical role across numerous industries such as mining, cement production, and chemical processing. The durability and performance of these grinding media have a direct influence on both operating costs and the overall efficiency of milling operations. When the lifespan of grinding media is extended, plants can benefit from reduced replacement frequency, lower maintenance requirements, and less downtime, all of which contribute to improved production output. Additionally, longer-lasting grinding media help maintain consistent milling conditions, ensuring uniform particle size distribution and stable product quality over time. This article explores proven and efficient techniques designed to increase the service life of ball mill grinding media, ultimately leading to enhanced operational performance and significant reductions in long-term expenditures.

What non-destructive tests are used for grinding balls?

To reduce raw materials to fine and uniform particles, grinding balls are indispensable in the mining and mineral processing industries, where they are subjected to intense mechanical forces inside mills. The constant impact, abrasion, and wear that these hardened steel spheres endure make it critical to ensure their quality, structural integrity, and reliability. Even a minor defect can compromise mill efficiency, increase maintenance costs, and pose risks to operational safety. For this reason, manufacturers and mining operators increasingly rely on a range of non-destructive testing (NDT) techniques to verify the performance of grinding balls before and during use. These methods, which include ultrasonic testing, X-ray inspection, and surface crack detection, help identify hidden flaws without damaging the product. This article highlights the importance of NDT and examines the major methods currently applied to grinding balls for mining.