What are the typical manufacturing processes involved in producing high chrome steel grinding media cylpebs?

How Do Grinding Cylpebs Perform in Different Environments?

_1728977649906.webp)

Grinding cylpebs, widely employed across industries for reducing materials to fine powders, encounter a range of environmental conditions that can influence their performance. Understanding how grinding cylpebs behave in different environments is crucial for optimizing their efficiency and durability.

What Role Do Grinding Balls Play in Cement Production?

The Role of Chromium Casting Grinding Balls in Modern Manufacturing

In the realm of modern manufacturing, precision and efficiency are paramount. One often overlooked yet crucial component in various industrial processes is the chromium casting grinding ball. These robust spheres play a vital role in grinding, milling, and refining materials across multiple sectors. Let's delve into the world of chromium casting grinding balls and explore their significance in today's manufacturing landscape.

What are the maintenance requirements for high chrome grinding media?

High chrome grinding media play a crucial role in various industries, including cement production, mining, and power generation. These durable components are designed to withstand the rigors of grinding operations, but proper maintenance is essential to ensure their longevity and optimal performance. In this comprehensive guide, we'll explore the maintenance requirements for high chrome grinding media, helping you maximize their lifespan and efficiency.

Cement Grinding Media Balls: Benefits and Applications

In the realm of cement production, the efficiency and quality of the grinding process play a pivotal role in determining the final product's characteristics. At the heart of this process lie cement grinding media balls, essential components that significantly impact the overall production efficiency and cement quality. This article delves into the world of grinding media, exploring their types, applications, and crucial role in modern cement plants.

How do you maintain grinding balls for optimal performance?

Grinding Balls for Mining are essential for optimal performance in mineral processing. Regular cleaning routines help remove build-up and prevent material residue. Periodic inspections should be conducted to identify wear or damage, replacing balls as needed. Storing balls in dry environments prevents corrosion and maintains integrity. Adjusting mill parameters, such as rotation speed and ball charge, minimizes wear. Use high-quality grinding media suited to the application, considering ore hardness and desired particle size. A systematic maintenance schedule, with documented wear rates and performance, helps extend ball lifespan and ensures efficient operations.

Future Trends in High Chrome Grinding Media: What to Expect

.webp)

As the industrial landscape continues to evolve, the high chrome grinding media sector is witnessing significant transformations. These changes are driven by technological advancements, sustainability concerns, and shifting market demands. In this comprehensive exploration, we'll delve into the emerging trends and future expectations for high chrome grinding media, providing valuable insights for industry professionals and enthusiasts alike.

What are the critical properties of ceramic ball mill media?

Ceramic ball mill media play a crucial role in various industrial grinding processes, offering unique advantages over other materials. Understanding the critical properties of these ceramic balls is essential for optimizing milling operations and achieving desired outcomes. In this comprehensive guide, we'll explore the key characteristics that make ceramic media highly effective in ball mill applications.

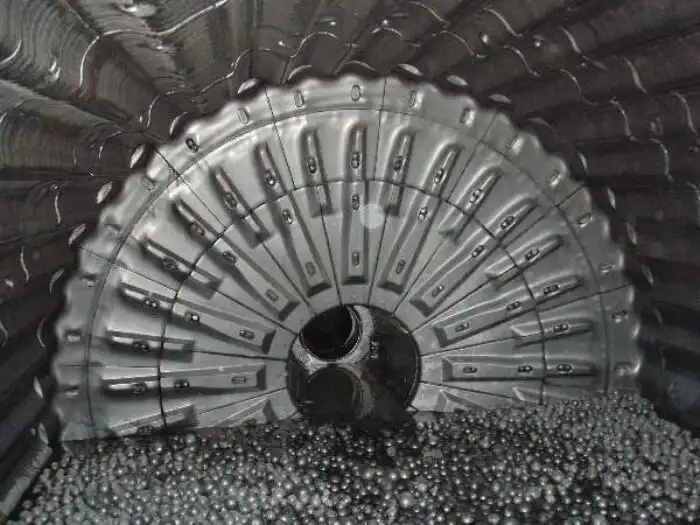

High Chrome vs White Cast Iron Mill Liners: A Comparative Guide

In the world of industrial grinding, the choice of mill liners can significantly impact operational efficiency and cost-effectiveness. This comprehensive guide delves into the comparison between high chrome and white cast iron mill liners, two popular options in the industry. We'll examine their key differences, conduct a cost-benefit analysis, and compare their wear rates in abrasive environments. Whether you're in the mining, cement, or power generation sector, this information will help you make an informed decision for your grinding operations.

What is the effect of moisture on grinding media wear in a ball mill?

The efficiency and efficacy of ball mill operations in many sectors are greatly influenced by grinding media. When it comes to grinding media, moisture is one of the most underrated factors that affects both performance and longevity. If you want to know how to get the most out of your ball mill while keeping costs down, this article is for you. It explores the complex link between moisture and grinding media wear.

How to track ball mill media consumption in a large-scale grinding circuit?

Cement manufacturing, mining, and mineral processing are just a few of the numerous sectors that rely on ball mills to function efficiently. Ensuring precise monitoring of ball mill media consumption is essential for sustaining peak performance. This article delves into several techniques for measuring media wear rates, optimising media replacement in large-scale grinding circuits, and cutting-edge tracking systems.