Market Trends and Forecasts for Grinding Balls

As a pivotal component in industries such as mining, cement, and power generation, grinding balls play an essential role in the comminution process. Understanding the market trends and forecasts for grinding balls is crucial for stakeholders seeking to navigate this dynamic landscape. In this article, I delve into the current state of the grinding balls market, analyze key trends, and offer insights into future forecasts based on credible sources and industry expertise.

Efficiency in Stirred Mills: Impact of Grinding Balls

As the demand for efficiency in stirred mills continues to escalate, understanding the impact of grinding balls is essential for success. By delving into the intricacies of ball dynamics, considering key factors influencing efficiency, and embracing innovations driving progress, operators can optimize their milling operations for maximum performance and productivity.

How to dispose of worn-out ball mill media responsibly?

Ball mill media, essential components in various industrial grinding processes, eventually wear out and require replacement. As responsible stewards of the environment, it's crucial to understand and implement proper disposal methods for these materials. This comprehensive guide explores the responsible disposal of worn-out ball mill media, focusing on recycling options, environmental regulations, and cost considerations.

Understanding Grinding Ball Wear Mechanisms

Grinding ball wear is a critical factor affecting the efficiency and cost-effectiveness of grinding processes in various industries such as mining, cement, and utilities. As a crucial component of ball mills and other grinding equipment, grinding balls undergo wear during operation, leading to reduced efficiency, increased energy consumption, and higher maintenance costs. Understanding the mechanisms behind grinding ball wear is essential for optimizing grinding operations and maximizing productivity.

What causes media agglomeration in continuous mills?

Continuous mills play a crucial role in various industries, from cement production to mineral processing. These mills rely on ball mill media, typically balls or cylpebs, to efficiently reduce particle sizes. However, a common challenge faced in these operations is media agglomeration – the unwanted clumping or sticking together of grinding media. This phenomenon can significantly impact mill performance, product quality, and operational efficiency. In this comprehensive guide, we'll explore the primary causes of media agglomeration in continuous mills and discuss effective prevention techniques.

What materials are grinding media balls?

From the processing of minerals to the production of pharmaceuticals, grinding media balls are an essential part of many industrial processes. The job of these little but powerful spheres is to reduce materials to tiny particles, make sure that the particles are of the same size, and improve the quality of the final product. Learn more about the product materials, their characteristics, and how to choose the one that's most suited to your needs with this detailed guide.

What is the function of the grinding media balls?

The mining, cement, and material processing sectors are just a few that rely heavily on grinding media balls. Ball mills and other grinding machinery rely on these little yet powerful spheres to reduce materials to fine particles. The significance of grinding media balls in industrial processes will be illuminated as we investigate their roles, methods, and efficiency considerations in this exhaustive guide.

Load Impact: Effect on Milling Circuits

In the realm of milling circuits, the significance of load impact cannot be overstated. As a pivotal component in various industrial processes, milling circuits play a crucial role in reducing particle size and facilitating material extraction. However, the impact of load fluctuations on milling circuits is a multifaceted phenomenon that demands careful consideration. In this comprehensive analysis, we delve into the intricate dynamics of load impact and its implications for milling circuits, shedding light on key aspects that influence efficiency, performance, and overall productivity.

How does media influence slurry rheology in the mill?

Understanding the complex interplay between ball mill media and grinding media, as well as slurry rheology, is essential for optimizing the overall performance of ball mills. The physical and chemical characteristics of grinding media—including size, density, shape, and surface charge—play a significant role in influencing the flow behavior and viscosity of slurries within the mill. These factors affect how particles are suspended, mixed, and ground, ultimately impacting grinding efficiency and energy consumption. By gaining a deeper insight into how different aspects of grinding media interact with slurry rheology, operators can make informed decisions about media selection and process adjustments, thereby enhancing milling efficiency, reducing operational costs, and improving product quality.

Ultrafine Grinding Applications and Grinding Balls

As a specialist in the field of materials processing, I have delved into the realm of ultrafine grinding applications and the pivotal role that grinding balls play in achieving desired outcomes. In this comprehensive guide, I will explore the various applications of ultrafine grinding, the importance of selecting the right grinding balls, and how they contribute to the efficiency and effectiveness of the process.

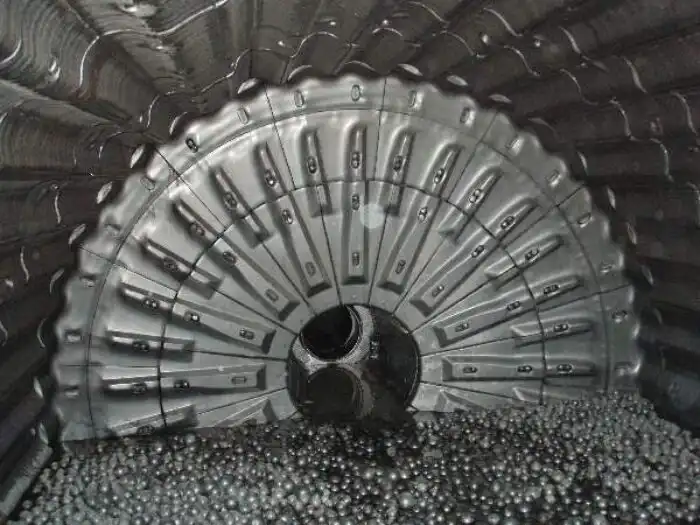

What is the process of grinding media balls production?

A number of sectors rely on grinding media balls, such as the cement, mining, and power generating industries. When it comes to grinding materials into very small particles, these spherical devices are indispensable. Creating high-quality goods that cater to our customers' varied demands is our forte here at NINGHU. The complex manufacturing process of these essential industrial instruments is explored in this article.

Selection Criteria for Different Milling Operations

In the realm of machining, selecting the appropriate milling operation is paramount to achieving optimal results. Each milling operation serves a distinct purpose, catering to various material types, shapes, and surface finishes. As a seasoned professional in the manufacturing industry, I've delved deep into the intricacies of milling operations and understand the critical importance of selecting the right method for each job. In this comprehensive guide, I will elucidate the selection criteria for different milling operations, providing invaluable insights for engineers, machinists, and enthusiasts alike.