Which industries or applications commonly use casting grinding media cylpebs?

Casting grinding media cylpebs are widely used in various industries for grinding purposes. These cylpebs, typically made from high-quality alloy steel or iron, are cylindrical in shape and are used in ball mills and similar grinding equipment. Their primary function is to help in the grinding process by efficiently reducing the size of the material being processed.

Why Use Steel Grinding Balls?

In businesses where processing processes are used to decrease molecule size, steel Grinding Ball assume a basic part. These circles are created from great steel, intended for their hardness, strength, and execution in crushing materials into fine powders. They are essential tools in the mining, cement production, and chemical processing industries due to their effectiveness in a variety of applications.

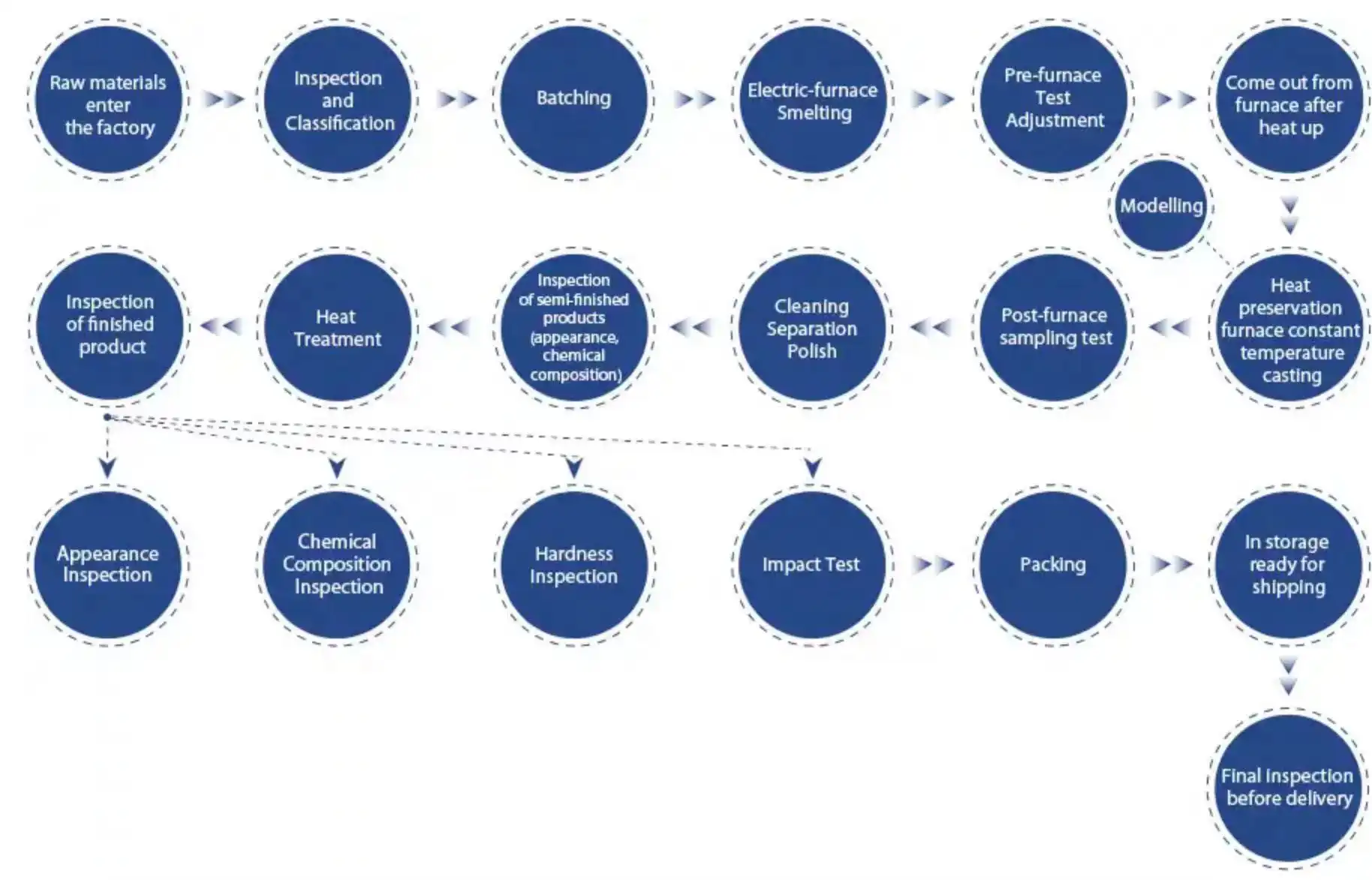

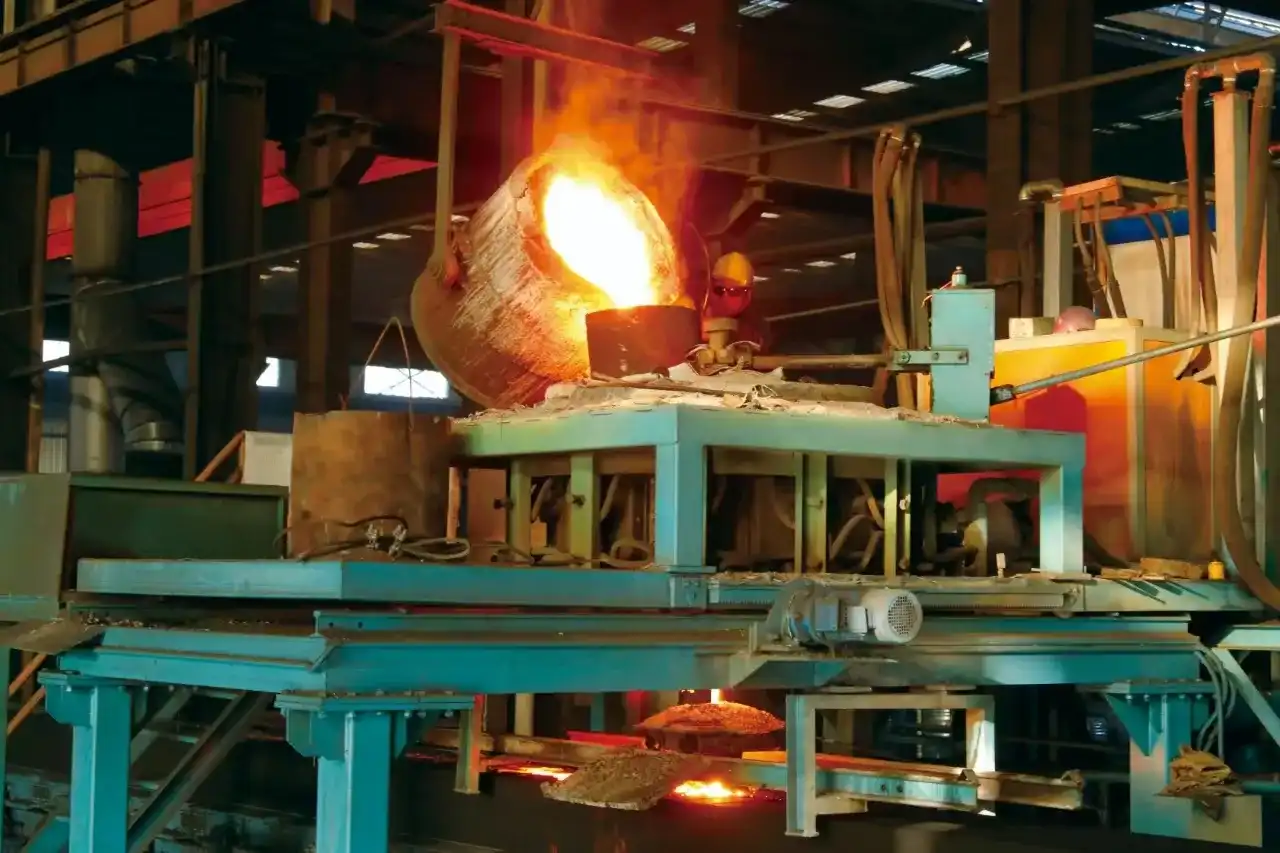

How are grinding balls manufactured?

Grinding balls are essential components used in various industrial sectors for pulverizing materials into fine particles. They are widely employed in mining, cement plants, power stations, and chemical industries to grind materials such as minerals, cement, and chemicals into finer powders for further processing. Grinding balls play a crucial role in various industrial processes where size reduction of raw materials is required. From mining to cement production, these spheres are key in transforming coarse materials into finely ground powders, essential for manufacturing processes across industries. Understanding how grinding balls are manufactured sheds light on the precision and complexity involved in producing these vital components.

How do casting grinding balls compare to forged grinding balls?

When it comes to grinding media for industrial applications, two primary types often come into consideration: casting grinding balls and forged grinding balls. Both have their unique attributes and applications, making the choice between them crucial for optimizing grinding processes. In this comprehensive guide, we'll delve into the differences between these two types of grinding media, exploring their manufacturing processes, characteristics, and suitability for various industries.

The Role of Chromium Casting Grinding Balls in Improving Material Processing

In the world of material processing, efficiency and precision are paramount. Industries ranging from cement production to metallurgy are constantly seeking ways to enhance their grinding processes. One solution that has gained significant traction is the use of chromium casting grinding balls. These specialized tools have revolutionized material processing, offering a blend of durability, performance, and cost-effectiveness that is hard to match.

What are the safety concerns associated with high chrome grinding media?

High chrome grinding media plays a crucial role in various industrial processes, particularly in mineral processing and cement production. While these grinding balls and cylpebs offer exceptional durability and efficiency, it's essential to understand and address the safety concerns associated with their use. This article delves into the key safety considerations for high chrome grinding media, providing valuable insights for industry professionals and plant operators.

How do you test the quality of grinding balls for mining?

Testing the quality of grinding balls for mining is crucial to ensure optimal performance and longevity in mineral processing operations. The quality assessment involves a combination of physical, chemical, and mechanical tests. These evaluations typically include hardness testing, impact resistance measurement, chemical composition analysis, and wear rate determination. Manufacturers and mining companies often employ standardized testing methods such as the SAG mill grinding ball test or the Bond abrasion test to evaluate the durability and efficiency of grinding media. Additionally, microstructure analysis using techniques like metallography can provide insights into the internal structure and potential performance of the grinding balls. By conducting comprehensive quality tests, mining operations can select the most suitable grinding balls that offer the best balance of hardness, toughness, and wear resistance for their specific mineral processing requirements.

The Science Behind Steel Balls for Ball Mills

In the world of industrial grinding, few components play as crucial a role as steel balls for ball mills. These seemingly simple spheres are the workhorses of material processing, responsible for breaking down raw materials into finer particles with precision and efficiency. Let's delve into the fascinating science that makes these steel balls an indispensable part of various industries, from mining to cement production.

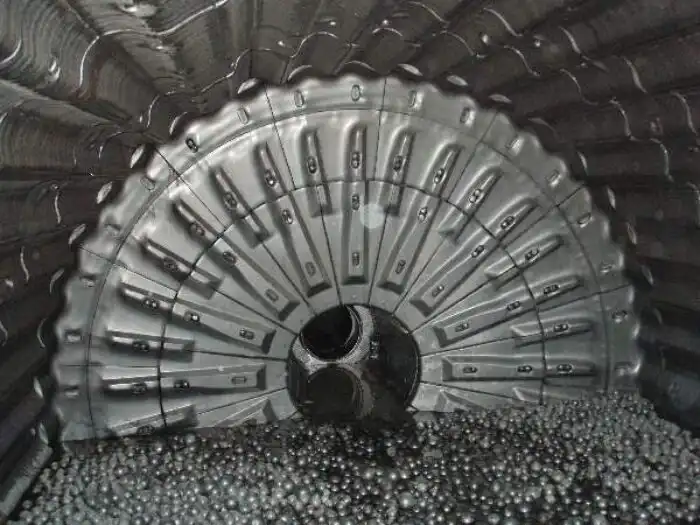

Grinding Media in Ball Mills: A Comprehensive Guide

In the world of industrial processing, ball mills play a crucial role in reducing materials to fine powders. At the heart of these mills lie the unsung heroes: grinding media. These small but mighty components are essential for efficient material reduction across various industries. In this comprehensive guide, we'll delve into the intricacies of grinding media in ball mills, exploring their shapes, sizes, materials, and how to choose the right ones for your specific needs.

Is ball mill media suitable for sensitive product purity?

In the world of industrial grinding and milling, the choice of grinding media can significantly impact the final product's quality, especially when dealing with sensitive materials that require high purity. Ball mill media, while widely used in various industries, presents both advantages and challenges when it comes to maintaining product purity. This article delves into the suitability of ball mill media for sensitive applications, exploring FDA-compliant options, metal contamination risks, and the comparison between ceramic and zirconia media for high-purity grinding processes.

Cast Iron Mill Liners: Wear Resistance and Service Life Analysis

In the world of industrial grinding, cast iron mill liners play a crucial role in maintaining efficiency and longevity of ball mills. These essential components protect the mill's inner walls from wear and tear while optimizing the grinding process. This comprehensive analysis delves into the factors affecting the wear resistance and service life of cast iron mill liners, comparing testing methodologies, and examining real-world data from copper concentrators.

How to select ball mill media for high-viscosity slurry applications?

A key decision that can have a significant impact on both process efficiency and final product quality in industrial grinding is the selection of the right ball mill media, especially when dealing with applications involving high-viscosity slurries. Choosing unsuitable media can lead to problems such as inadequate particle size reduction, excessive energy consumption, or uneven mixing, all of which can compromise performance. NINGHU, a top ball mill media manufacturer, understands the challenges that operators often face during this process and provides professional guidance to ensure that the proper media are selected for each unique application. By learning what characteristics to look for in grinding media, how to address common operational issues, and which performance factors matter most, readers of this article will gain valuable insights to enhance efficiency and maintain consistent quality in demanding grinding environments.