Corrosion Resistance of Grinding Balls

In the realm of industrial processes, the efficacy of grinding balls plays a pivotal role in ensuring the efficiency and longevity of various operations. Among the myriad factors influencing their performance, corrosion resistance stands out as a critical determinant. In this comprehensive exploration, we delve into the nuances of corrosion resistance concerning grinding balls. From understanding the fundamental components to down to earth suggestions, this talk points to prepare experts and devotees alike with priceless experiences into optimizing mechanical processes.

How do I choose grinding media?

What is the Lifespan of Grinding Balls?

Grinding Ball are a necessary part of a lot of industrial processes, especially the mining and cement industries. They make it easier to extract or process minerals and materials by crushing and grinding them into a fine powder. For maximizing operational efficiency and lowering production costs, it is essential to comprehend the lifespan of grinding balls. This article digs into the variables impacting the life expectancy of crushing balls and gives bits of knowledge into expanding their sturdiness and execution.

What are the safety considerations when handling grinding balls?

Grinding balls are essential tools in various industrial processes such as mining, cement production, and ore processing. Their role in grinding and milling operations makes them crucial for achieving desired particle sizes and material properties. However, handling these balls requires careful attention to safety to prevent accidents and ensure workplace health.

What factors influence the wear resistance of high chrome grinding balls?

High chrome grinding balls are essential components in various industrial processes, particularly in mining, cement production, and material processing. These robust spheres play a crucial role in pulverizing materials, and their wear resistance is paramount to their effectiveness and longevity. Understanding the factors that influence the wear resistance of high chrome grinding balls is vital for optimizing their performance and maximizing their lifespan.

What are the common problems associated with casting grinding balls?

Casting grinding balls play a crucial role in various industries, from cement production to mining operations. These spherical tools are designed to crush and grind materials efficiently, but they're not without their challenges. In this comprehensive guide, we'll explore the common issues that arise with it and provide insights into how to address them effectively.

Maximizing Efficiency with Milling Balls

.webp)

In the world of industrial grinding and material processing, milling balls play a crucial role in enhancing efficiency and productivity. These small yet mighty spheres are the unsung heroes of many manufacturing processes, from mining to cement production. Let's delve into the world of milling balls and discover how they can revolutionize your grinding operations.

Maximizing Mineral Processing with Grinding Media Balls

.webp)

In the world of mineral processing, efficiency is paramount. One crucial element that plays a significant role in this process is the use of high chrome grinding media balls. These unassuming spheres are the workhorses of mineral processing, responsible for breaking down ore into finer particles, enabling better mineral extraction. At NINGHU, we understand the importance of high-quality grinding media and its impact on your operations. Let's delve into the world of grinding media balls and explore how they can maximize your mineral processing efficiency.

What are key considerations for grinding media selection in regrinding?

Selecting the right grinding media is crucial for optimizing regrinding processes in various industries, including mining, cement production, and materials processing. The choice of grinding media can significantly impact the efficiency, cost-effectiveness, and quality of the final product. In this comprehensive guide, we'll explore the key considerations for ball mill grinding media applications, helping you make informed decisions to enhance your operations.

What industries commonly use high chrome steel grinding media balls?

High chrome steel grinding media balls have become an indispensable component in various industrial processes, revolutionizing the way materials are ground and refined. These robust spheres, crafted from high-quality chromium alloy steel, offer exceptional wear resistance and durability, making them ideal for a wide range of applications across multiple sectors. In this comprehensive guide, we'll explore the industries that rely heavily on high chrome steel grinding media balls and delve into the reasons behind their widespread adoption.

Cylpebs for Wet vs Dry Grinding: What You Need to Know

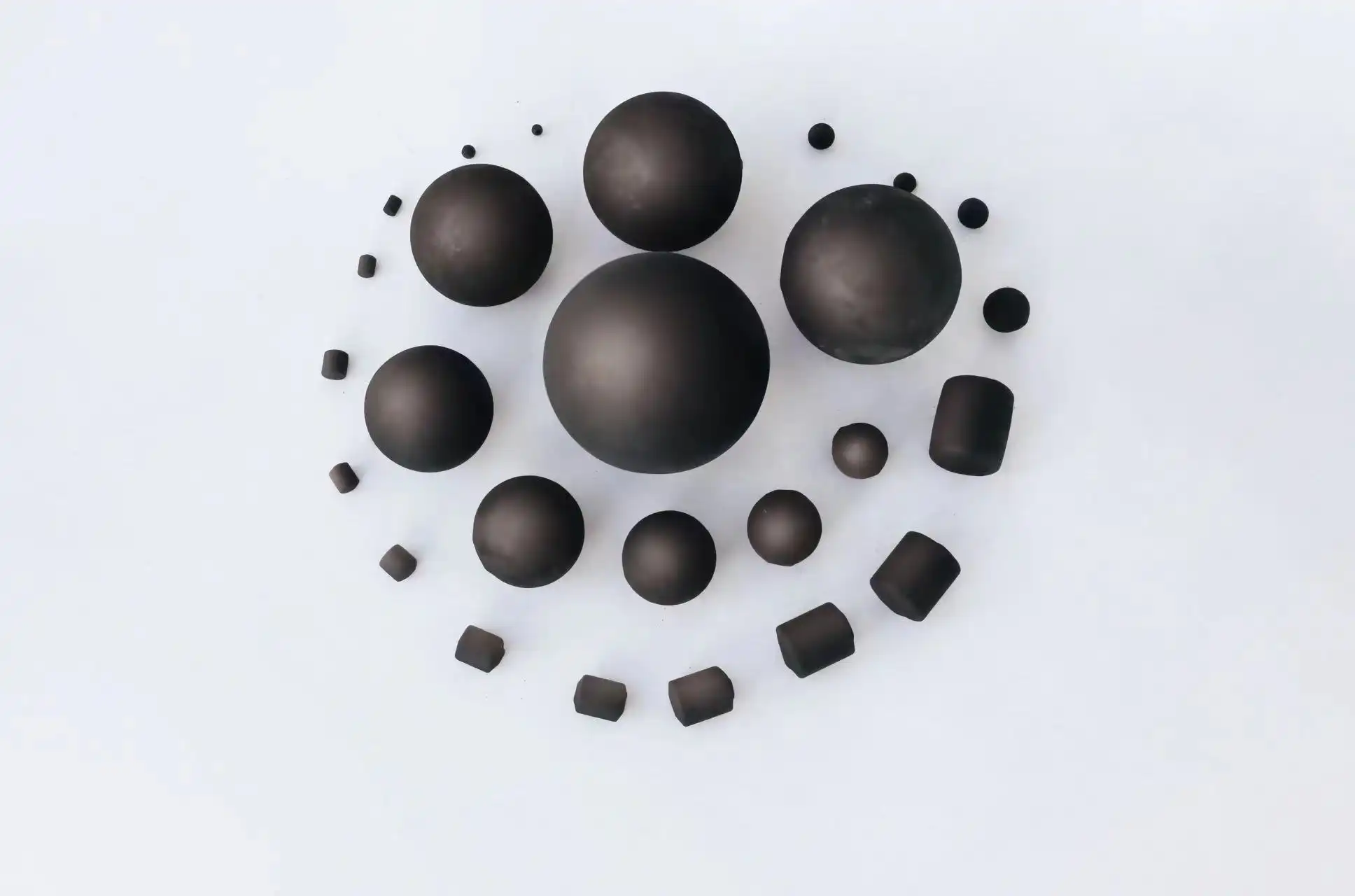

Making the decision between wet and dry operations in industrial grinding can have a significant impact on both overall efficiency and the final product quality. Each method presents unique benefits and challenges, making the choice a critical factor for manufacturers and operators. Due to their versatility and consistent performance, cylpebs grinding media have recently gained widespread recognition for their ability to adapt seamlessly to both dry and wet grinding environments. Their distinctive design enhances grinding efficiency while maintaining uniform particle size distribution in a variety of settings. This article takes a closer look at the applications and advantages of cylpebs across different grinding conditions, helping you evaluate the options thoroughly and make well-informed decisions based on your specific operational requirements.

How High Chrome Grinding Media Is Used for Mineral Processing?

In order to get useful materials out of raw materials, mineral processing is an essential procedure. The use of high chrome grinding media ball is a crucial part of this procedure. In order to separate rich minerals from ore, these specialised balls are crucial. This detailed guide will examine the environmental effect, advantages, and use of high chrome grinding media in mineral processing.