Role of Grinding Balls in Mineral Processing

In the domain of mineral handling, the part of crushing balls is vital. As a crucial component in the comminution handle, Grinding media encourage the pulverizing and pounding of metal particles, empowering proficient extraction of important minerals. In this article, we dive into the multifaceted centrality of pounding balls in mineral preparing, investigating their capacities, sorts, and significance in optimizing mineral handling operations.

Why Choose Cylpebs Grinding Media?

Cylpebs grinding media offer unique advantages over conventional ball or rod-shaped media that can improve the efficiency and cost-effectiveness of a variety of grinding applications. Cylpebs are an alternative to the more typical spherical or rod-like grinding mediums because of their cylindrical shape. As a result of this particular calculation, they are an important option for getting the best crushing results under certain conditions. Let's take a closer look at the reasons why Cylpebs grinding media might be the best choice for your grinding needs.

How to Store Grinding Balls?

Putting away Grinding Ball appropriately is urgent for keeping up with their quality and viability in modern activities. Whether ceramic balls used in chemical processing or steel balls used in mining, proper storage ensures their performance and longevity. This article looks at the best ways to store grinding balls to make sure they last as long as possible and work as well.

How does the shape of grinding balls affect milling efficiency?

In the realm of industrial processes like milling and grinding, efficiency is paramount. The choice of grinding balls plays a significant role in determining milling efficiency and performance. From the material composition to the shape and size, each aspect can affect how materials are ground down and how efficiently the process is carried out.

How can you select the appropriate size of high chrome grinding balls for your application?

Selecting the right size of high chrome grinding balls is crucial for optimizing your grinding process. Whether you're in the cement, mining, or power generation industry, choosing the appropriate ball size can significantly impact your operation's efficiency and cost-effectiveness. This comprehensive guide will walk you through the key factors to consider when selecting high chrome grinding balls, ensuring you make an informed decision for your specific application.

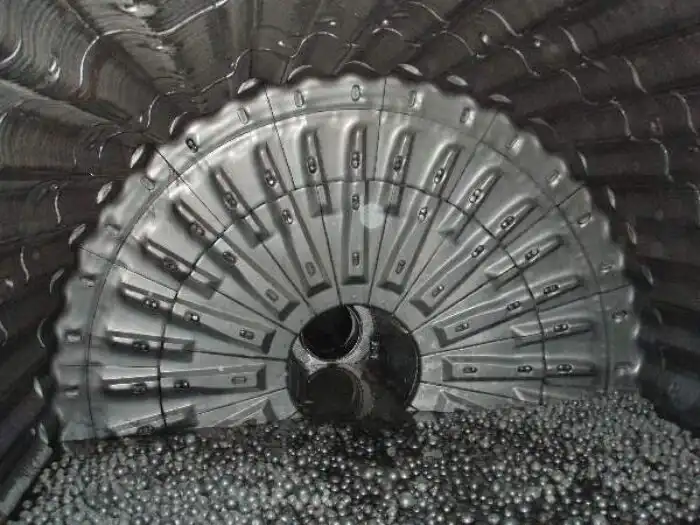

How do I maintain casting grinding balls for optimal performance?

Casting grinding balls are indispensable components in various industries, including cement production, metallurgy, and mining. These robust spheres play a crucial role in pulverizing materials to achieve desired particle sizes. To ensure longevity and maintain peak performance, proper maintenance of it is essential. In this comprehensive guide, we'll explore effective strategies to keep your grinding media in top-notch condition, maximizing efficiency and minimizing downtime.

Milling Balls in Modern Manufacturing

In the realm of modern manufacturing, milling balls play a pivotal role in various industrial processes. These small yet mighty spheres are the unsung heroes behind the production of countless everyday items, from the cement in our buildings to the minerals in our electronics. As we delve into the world of milling balls, we'll explore their key roles, compare different types, and peek into the future of this essential manufacturing component.

The Future of high chrome grinding media balls in Industry

The mining and mineral processing industries are constantly evolving, and one area that's seeing significant advancements is the technology behind high chrome grinding media balls. These essential components play a crucial role in the mineral extraction process, and their future looks promising. In this article, we'll explore the latest innovations, environmental considerations, and how these advances are enhancing mineral extraction efficiency.

What are the best practices for grinding media addition to prevent surges?

Ball mill grinding media is a critical aspect of ball mill operation, particularly in industries like cement manufacturing, mining, and mineral processing. Proper management of grinding media not only ensures optimal mill performance but also prevents surges that can lead to inefficiencies and potential equipment damage. In this comprehensive guide, we'll explore the best practices for grinding media addition, focusing on strategies to maintain stable mill operation and maximize productivity.

How do you choose the right size of high chrome steel grinding media balls?

Selecting the appropriate size of high chrome steel grinding media balls is crucial for optimizing grinding efficiency in various industrial applications. Whether you're involved in cement production, metallurgical mining, or thermal power generation, understanding the factors that influence the choice of grinding media size can significantly impact your operational effectiveness. This comprehensive guide will explore the key considerations and provide valuable insights to help you make informed decisions when choosing high chrome steel grinding media balls.

Cylpebs Grinding Media: Environmental and Economic Considerations

Choosing the right grinding medium is an important factor in industrial grinding operations that affects efficiency, cost-effectiveness, and environmental impact. With its distinct benefits over more conventional grinding balls, cylpebs grinding media has quickly become a formidable opponent. Cylpebs have the ability to transform grinding processes, and this article explores the economic and environmental implications of using them in several sectors.

What are key properties of high chrome grinding balls?

Mining, cement manufacturing, and material processing are just a few of the many industrial activities that rely on high chrome grinding balls. To obtain the required particle sizes in grinding and crushing, these specialised balls are essential. To maximise grinding efficiency and equipment longevity, it is crucial to understand the fundamental features of high chrome grinding balls. This detailed tutorial will explore the important features that make high chrome grinding balls the go-to for many different types of businesses.