Grinding Balls: Vital for Cement Industries

Grinding Balls play a pivotal part in the cement industry, where they are utilized to smash and crush crude materials into a fine powder. These balls are regularly made from different materials such as steel, press, ceramic, or indeed elastic, depending on the application and necessities of the cement fabricating handle. In this article, we will dig into the significance of pounding balls in cement generation and investigate their different employments and functionalities inside the industry.

How to Replace Grinding Balls?

It is essential to change the Grinding Ball in a mill so that the material is effectively ground and the machine runs at its best. Grinding media maintenance and replacement are crucial to operational efficiency and cost-effectiveness in mining, mineral processing, or cement plants. This article investigates the fundamental stages and contemplations associated with supplanting crushing balls, resolving normal inquiries and giving pragmatic experiences accumulated from top assets in the field.

What are the most common sizes of grinding balls for different applications?

What are the typical applications of high chrome grinding balls in mining and cement?

High chrome grinding balls are indispensable components in various industries, including cement production, mining, and power generation. These robust spheres play a crucial role in grinding and pulverizing materials, contributing significantly to the efficiency of industrial processes. To ensure optimal performance and longevity of it, proper cleaning and maintenance are paramount. This comprehensive guide will delve into the intricacies of caring for these essential industrial tools, providing valuable insights for professionals and enthusiasts alike.

5 Creative Ways to Use Grinding Balls

Grinding balls, particularly casting grinding balls, are essential components in various industrial processes. While their primary function is to crush and grind materials in mills, these versatile tools have found their way into some unexpected applications. In this article, we'll explore five creative ways to use grinding balls that you might not have considered before.

Environmental Impact of Milling Balls

.webp)

In the world of industrial grinding, milling balls play a crucial role in various sectors, including mining, cement manufacturing, and power generation. However, as our global focus shifts towards sustainability, it's essential to consider the environmental impact of these essential components. This article delves into eco-friendly options, waste reduction strategies, and responsible disposal methods for milling balls, offering valuable insights for industries seeking to minimize their ecological footprint.

What maintenance practices can extend the life of high chrome grinding balls?

High chrome grinding balls are indispensable components in various industries, including cement production, mining, and power generation. These robust spheres play a crucial role in grinding and pulverizing materials, contributing significantly to the efficiency of industrial processes. To ensure optimal performance and longevity of it, proper cleaning and maintenance are paramount. This comprehensive guide will delve into the intricacies of caring for these essential industrial tools, providing valuable insights for professionals and enthusiasts alike.

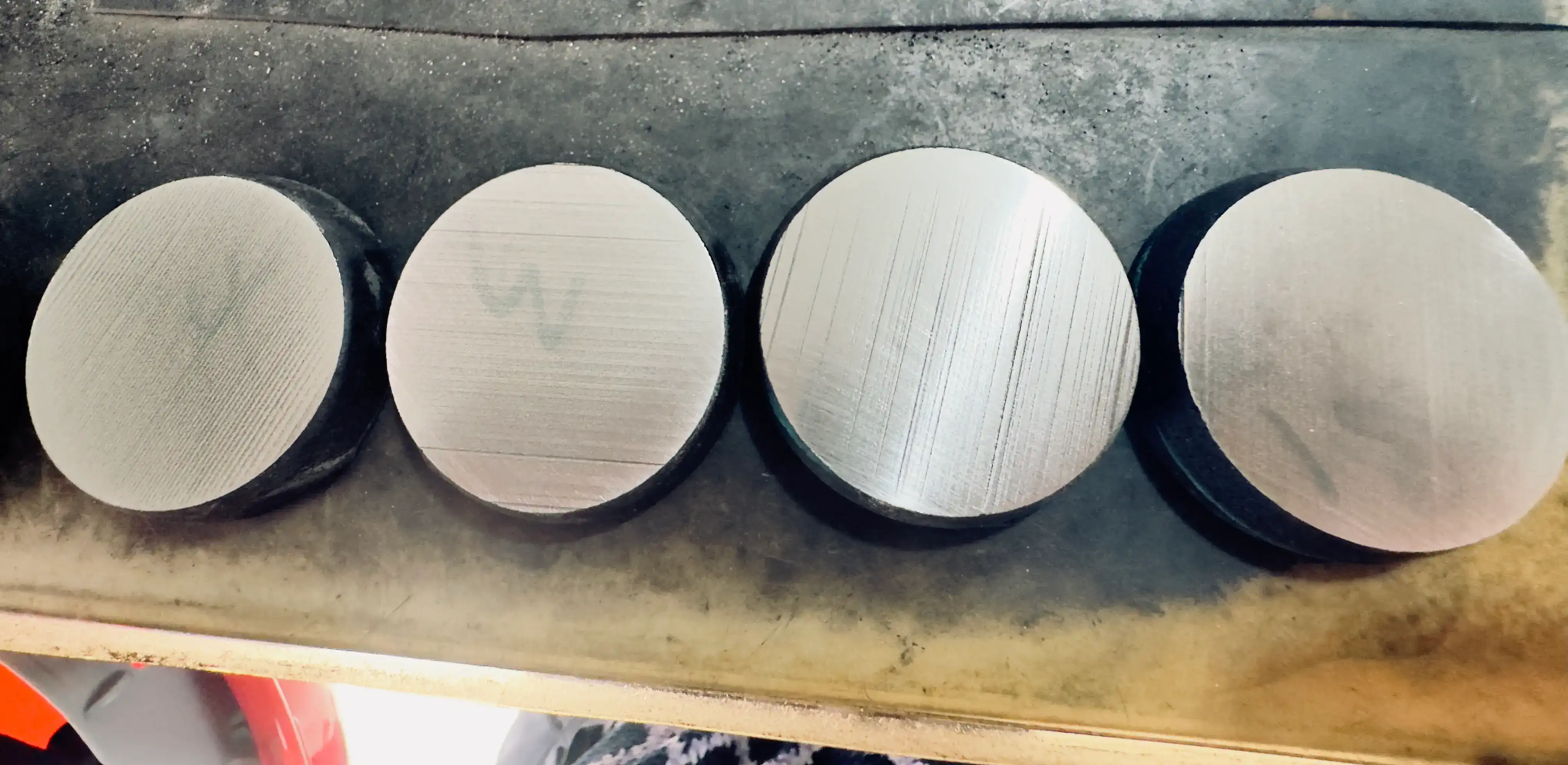

The Ultimate Guide to Grinding Media Steel Balls

In the world of industrial processing, grinding media steel balls play a pivotal role in transforming raw materials into valuable resources. These unassuming spheres are the unsung heroes of industries ranging from mining to cement production, enabling efficient size reduction and material refinement. In this comprehensive guide, we'll delve into the intricate world of grinding media steel balls, exploring their nature, selection criteria, and the myriad benefits they offer to various industrial applications.

High chrome grinding media balls: Benefits & Uses

In the world of industrial grinding and milling, the choice of grinding media can significantly impact operational efficiency and product quality. Among the various options available, high chrome grinding media balls have emerged as a top choice for many industries. These robust spheres play a crucial role in the comminution process, breaking down materials into finer particles with impressive efficiency. Let's delve into the benefits and uses of these remarkable grinding tools.

Can grinding media conductivity affect electrostatic grinding?

In the world of industrial grinding processes, electrostatic phenomena play a crucial role in determining the efficiency and effectiveness of particle size reduction. One often overlooked factor in this process is the conductivity of the ball mill grinding media used. This article delves into the intriguing relationship between grinding media conductivity and electrostatic grinding, exploring how this seemingly minor detail can have significant impacts on the overall grinding process.

What are the advantages of using high chrome steel grinding media balls over other types?

In the world of industrial grinding processes, the choice of grinding media can significantly impact efficiency, cost-effectiveness, and overall performance. High chrome steel grinding media balls have emerged as a popular option across various industries, offering numerous advantages over other types of grinding media. This article delves into the benefits of using high chrome steel grinding media balls and why they've become a preferred choice for many manufacturers.

How do high chrome grinding balls resist wear?

Many different types of businesses rely on high chrome grinding balls, such as those that produce cement, mine minerals, and generate electricity. They are very efficient and popular due to their great wear resistance. Their remarkable resilience and extended lifespan are the subject of this article's investigation.