The science behind media collision dynamics

The effectiveness of a ball mill grinding media system relies heavily on the frequency and intensity of collisions between grinding media. These collisions are responsible for breaking down materials into finer particles, making them a critical factor in the overall grinding process.

Understanding the cascading effect

As the mill rotates, grinding media are lifted along the inner wall of the mill. At a certain point, they begin to cascade down, creating a waterfall-like effect. This cascading motion is where the majority of grinding occurs, as media collide with each other and the material being ground.

The role of centrifugal force

The speed at which the mill rotates directly influences the centrifugal force acting on the grinding media. This force, in turn, affects how high the media are lifted before they begin to fall, impacting the intensity and frequency of collisions.

Optimizing mill speed for efficient grinding

Finding the optimal mill speed is crucial for maximizing grinding efficiency while minimizing wear on both the ball mill grinding media and the mill itself.

The concept of critical speed

Critical speed is defined as the rotational speed at which the centrifugal force exactly balances the gravitational force acting on the grinding media at the top of the mill. Operating a mill at its critical speed would cause the media to simply rotate with the mill, resulting in no grinding action.

Ideal operating speed range

Most ball mills operate at approximately 65-75% of their critical speed. This range has been found to provide the best balance between collision frequency and impact force. At these speeds, the grinding media reach an optimal height before cascading down, creating effective grinding conditions.

Impact of mill diameter

The ideal mill speed can vary depending on the diameter of the mill. Larger diameter mills generally operate at lower speeds relative to their critical speed, while smaller mills may operate at higher percentages of their critical speed.

Balancing speed and wear: Finding the sweet spot

While increasing mill speed can lead to higher collision frequencies, it's essential to consider the impact on wear rates and overall efficiency.

The wear factor

Higher speeds typically result in increased wear on both the grinding media and the mill lining. This wear can lead to more frequent replacements and increased operational costs. As a reputable grinding media manufacturer, NINGHU produces high-quality media designed to withstand the rigors of high-speed operations.

Energy consumption considerations

Operating mills at higher speeds also requires more energy. It's crucial to find a balance between grinding efficiency and energy consumption to optimize overall operational costs.

Tailoring speed to material characteristics

Different materials may require different optimal speeds for efficient grinding. Harder materials might benefit from higher speeds to increase impact force, while softer materials may achieve better results at lower speeds with higher media loads.

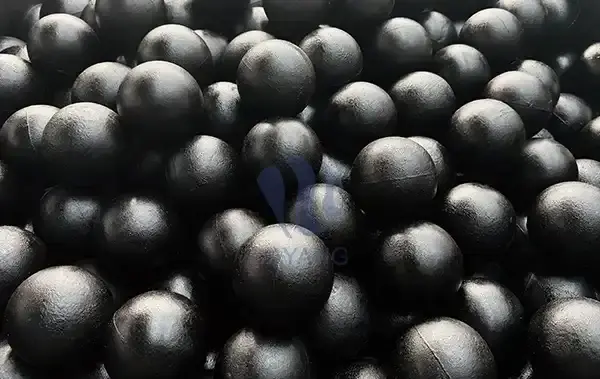

The importance of media size and composition

The size and composition of the ball mill grinding media can significantly influence the optimal operating speed. Larger, heavier media may require lower speeds to achieve the same collision frequency as smaller, lighter media.

Monitoring and adjusting

Regular monitoring of grinding performance and media wear is essential for maintaining optimal efficiency. Mills may require periodic speed adjustments to account for changes in media size due to wear or variations in the material being ground.

Advanced control systems

Modern mills often incorporate advanced control systems that can automatically adjust mill speed based on various parameters, including power draw, sound levels, and vibration. These systems help maintain optimal grinding conditions throughout the grinding process.

The role of mill filling

The degree to which a mill is filled with grinding media and material also affects the optimal operating speed. Higher fill levels may require slightly lower speeds to prevent over-grinding and excessive wear.

Considering throughput requirements

When determining the ideal mill speed, it's important to consider the required throughput. Higher speeds may increase grinding rate but could potentially lead to over-grinding or reduced efficiency if not properly balanced with other operating parameters.

The impact of lifter design

The design of mill lifters can significantly influence the motion of grinding media and, consequently, the optimal operating speed. Well-designed lifters can enhance media motion and collision frequency at lower speeds, potentially reducing wear and energy consumption.

Experimental optimization

While theoretical calculations provide a starting point, experimental optimization is often necessary to determine the ideal mill speed for specific applications. This may involve running trials at various speeds and analyzing the resulting product quality and energy efficiency.

Conclusion

To achieve effective grinding operations, it is essential to understand and optimise the connection between mill speed and media collision frequency. Operators may produce better milling outcomes by fine-tuning the operation by carefully examining aspects including critical speed, media characteristics, and material qualities.

Providing high-quality grinding media that perform superbly throughout a broad variety of operating situations is NINGHU's first priority as a leading grinding media manufacturer. Our products are designed to be very durable and efficient in high-speed milling operations, thanks to our knowledge of wear-resistant materials.

Ready to optimize your grinding process?

Do not hesitate to contact our team of specialists if you are seeking to enhance the efficiency of your milling operation or want assistance in choosing the appropriate ball mill grinding media for your particular application. Contact us at sales@da-yang.com or sunny@da-yang.com to discuss how NINGHU can help you achieve superior grinding results.