Corrosion resistance and performance in wet conditions

High chrome grinding balls excel in wet grinding applications due to their exceptional corrosion resistance and durability. The high chromium content in these balls, typically ranging from 10% to 30%, forms a protective layer that shields the ball from chemical attacks and oxidation.

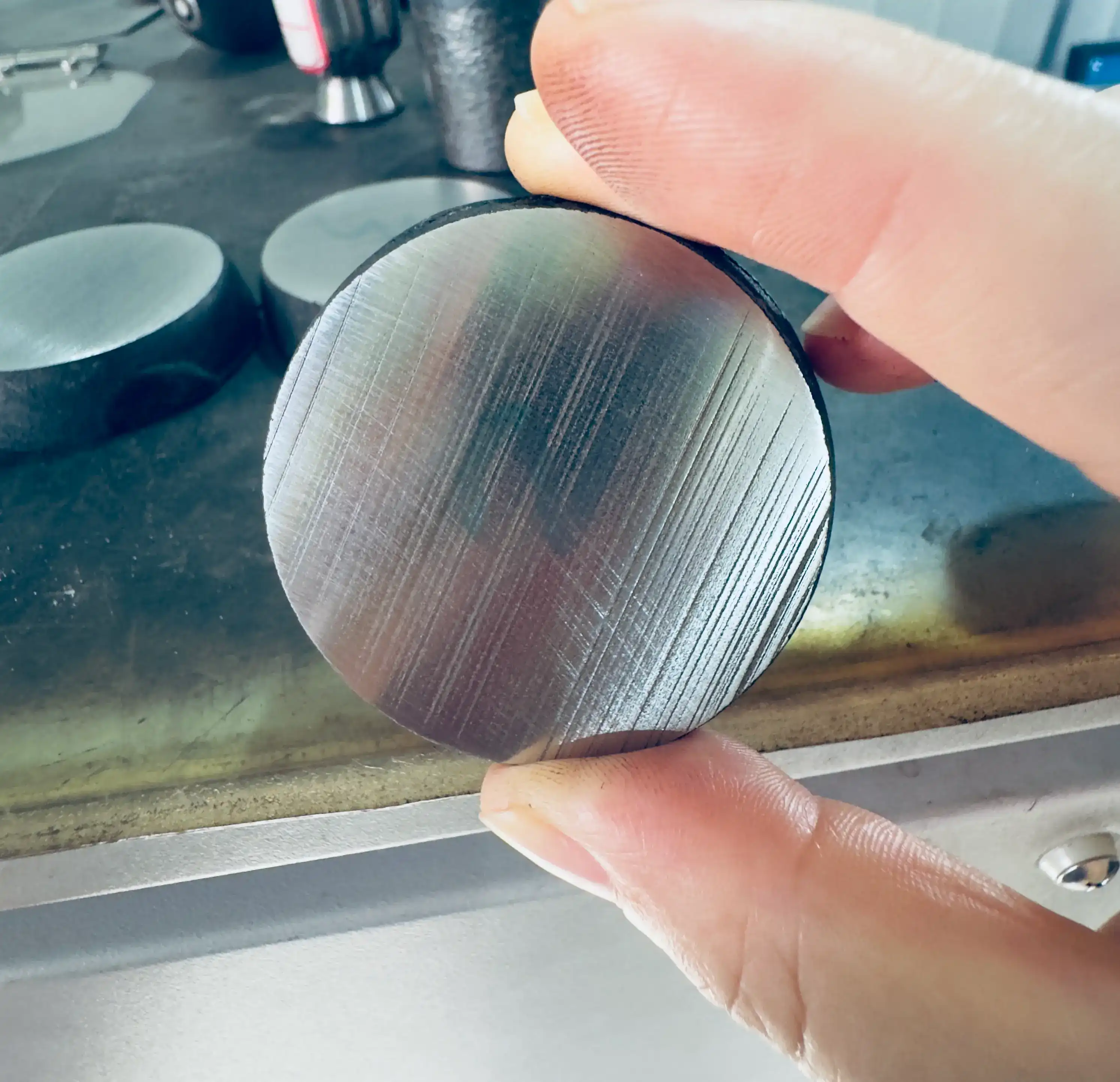

Superior corrosion resistance

The chromium in these grinding balls reacts with oxygen to form a thin, invisible layer of chromium oxide on the surface. This layer acts as a barrier, preventing further oxidation and corrosion of the underlying metal. As a result, high chrome grinding balls maintain their structural integrity and performance even in highly corrosive environments.

Enhanced wear resistance

In addition to corrosion resistance, high chrome grinding balls exhibit excellent wear resistance in wet grinding conditions. The combination of a hard martensitic structure and chromium carbides dispersed throughout the material provides superior resistance to abrasion and impact. This characteristic ensures a longer lifespan and consistent grinding performance over extended periods.

Stability in varying pH levels

Wet grinding processes often involve slurries with different pH levels. High chrome grinding balls demonstrate remarkable stability across a wide range of pH conditions, from acidic to alkaline. This versatility makes them suitable for diverse applications in various industries.

Industries where wet grinding is preferred

Wet grinding is a common practice in several industries due to its efficiency and ability to produce finer particle sizes. High chrome grinding balls are particularly well-suited for these applications, offering superior performance and longevity.

Mining and mineral processing

In the mining industry, wet grinding is extensively used for ore processing. High chrome grinding balls are employed in ball mills to reduce the size of mineral particles and liberate valuable metals from their ores. The corrosion resistance of these balls is crucial in handling abrasive mineral slurries and chemically aggressive environments often encountered in mining operations.

Cement production

Cement manufacturing involves wet grinding of raw materials and clinker. High chrome grinding balls are used in cement ball mills to achieve the desired fineness of cement particles. Their wear resistance contributes to consistent cement quality and reduced maintenance costs.

Paper and pulp industry

In paper production, wet grinding is used to refine wood fibers and create pulp. High chrome grinding balls are utilized in pulp refiners to break down cellulose fibers and improve paper quality. The corrosion resistance of these balls is particularly beneficial in the chemically active environment of pulp processing.

Chemical processing

Various chemical processes involve wet grinding for particle size reduction and dispersion. High chrome grinding balls find applications in chemical reactors and mills, where their resistance to corrosive chemicals is invaluable.

Tips for maintaining grinding balls in wet environments

To maximize the performance and lifespan of high chrome grinding balls in wet grinding applications, consider the following maintenance tips:

Regular inspection and replacement

Implement a routine inspection schedule to assess the condition of grinding balls. Look for signs of excessive wear, cracking, or unusual surface degradation. Replace worn-out balls promptly to maintain grinding efficiency and prevent contamination of the ground material.

Optimal ball charge and size distribution

Ensure that the mill has the appropriate amount of ball charge and that the grinding balls are distributed in the appropriate size range. Using this method helps to spread the grinding load evenly, which in turn reduces the amount of wear that occurs in certain areas and extends the overall life of the grinding medium.

Control of slurry properties

Maintain a close eye on and maintain control over the parameters of the grinding slurry, including the temperature, pH, and concentration of the solids. Grinding balls can be protected from excessive wear and corrosion by ensuring that the conditions of the slurry are kept at their ideal level.

Proper mill operation

Always make sure to follow the recommended mill operating parameters, such as the feed rate and rotating speed settings. When the mill is either overloaded or underloaded, it can result in grinding that is inefficient and can also speed up the wear of the grinding balls.

Regular cleaning and maintenance

Implement a cleaning schedule for the grinding mill and associated equipment. Remove any buildup or residue that may affect the performance of grinding balls. Regular maintenance of mill liners and other components can also contribute to the longevity of grinding media.

Conclusion

High-chrome grinding balls work very well in wet grinding uses in many different types of industries. Because they don't rust or wear down easily and stay stable in a range of pH conditions, they are perfect for grinding processes that require a lot of power. Industries can get the most out of using high chrome grinding balls in their wet grinding processes by following good maintenance procedures and adjusting operating parameters as needed.

FAQ

Q: What is the typical chromium content in high chrome grinding balls?

A: High chrome grinding balls typically contain between 10% and 30% chromium, with the exact percentage depending on the specific application requirements.

Q: How do high chrome grinding balls compare to other grinding media in wet conditions?

A: High chrome grinding balls generally outperform other materials in wet conditions due to their superior corrosion resistance, wear resistance, and stability across various pH levels.

Q: Can high chrome grinding balls be used in both wet and dry grinding applications?

A: Yes, high chrome grinding balls are versatile and can be used in both wet and dry grinding applications. However, they are particularly well-suited for wet grinding due to their excellent corrosion resistance.

Maximize Your Wet Grinding Efficiency with NINGHU High Chrome Grinding Balls

In wet grinding uses, NINGHU high chrome grinding balls will work better than other balls. NINGHU is a top producer with more than 30 years of experience. They can make high-quality grinding media that fits your needs. Our modern production methods and strict quality control make sure that every batch is always of the highest quality. With NINGHU's corrosion-resistant, long-lasting high chrome grinding balls, you can improve the efficiency of your grinding and lower your costs. Contact our expert team today at sales@da-yang.com or sunny@da-yang.com to discuss how NINGHU can optimize your wet grinding processes as your trusted high chrome grinding ball supplier.

References

1. Smith, J. (2022). Advances in Wet Grinding Technologies for Mineral Processing. Journal of Mineral Engineering, 45(2), 78-92.

2. Johnson, R., & Brown, L. (2021). Performance Analysis of High Chrome Grinding Media in Cement Production. Cement and Concrete Research, 112, 203-215.

3. Garcia, M. et al. (2023). Corrosion Behavior of High Chrome Grinding Balls in Acidic Slurries. Corrosion Science, 167, 108523.

4. Thompson, K. (2020). Optimization of Ball Mill Operations Using High Chrome Grinding Media. Mining Engineering, 72(9), 52-61.

5. Lee, S., & Park, C. (2022). Impact of Grinding Media Properties on Wet Grinding Efficiency in the Paper Industry. TAPPI Journal, 21(3), 157-169.

6. Wilson, D. (2021). Maintenance Strategies for Maximizing Grinding Media Lifespan in Wet Grinding Applications. International Journal of Mineral Processing, 158, 116-128.