How are cylpebs grinding media manufactured step-by-step?

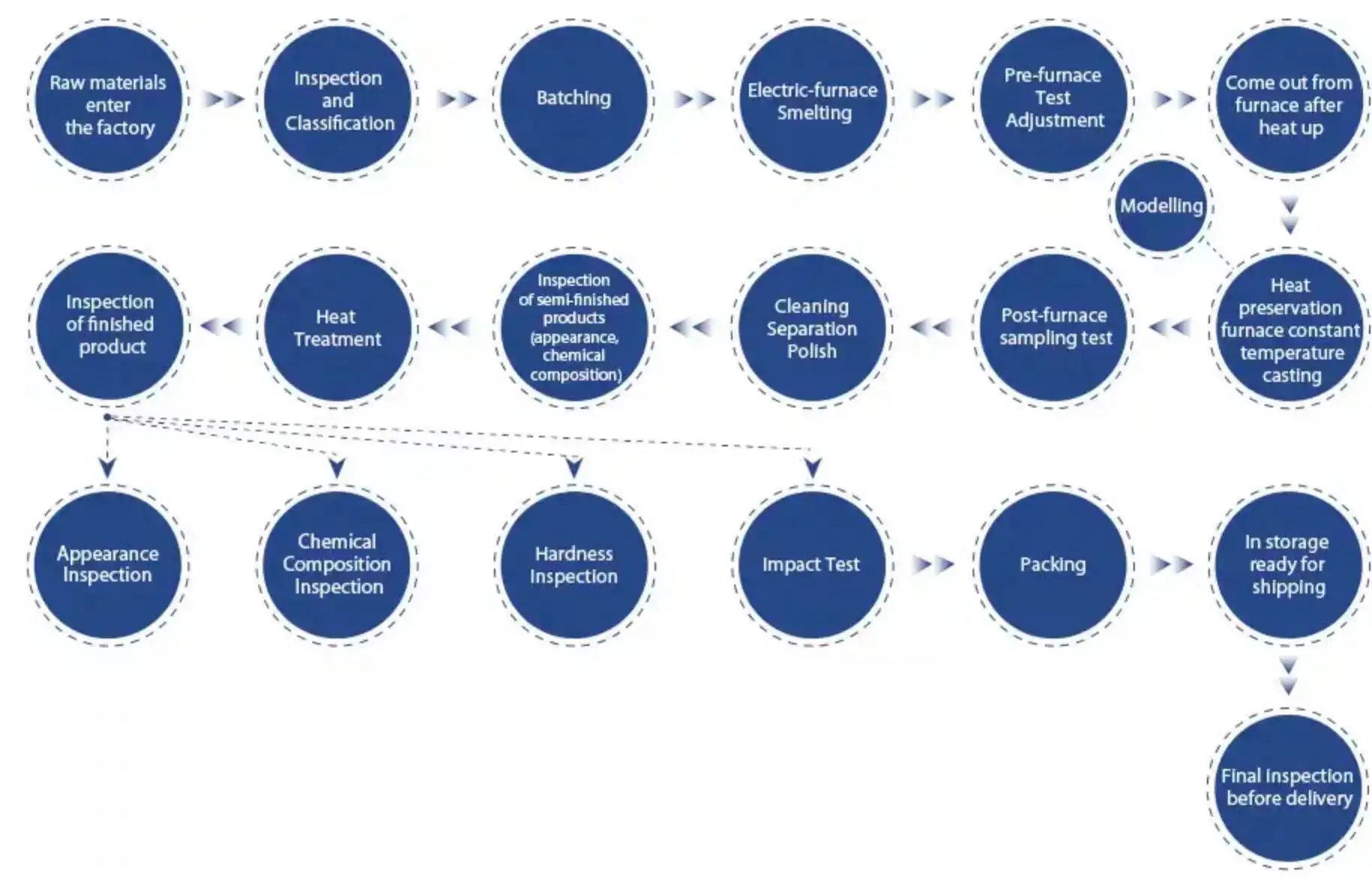

The production of cylpebs grinding media involves a series of carefully controlled steps to achieve the desired shape, size, and material properties. Let's examine the manufacturing process in detail:

Raw Material Selection and Preparation

The first step in manufacturing cylpebs is selecting the appropriate raw materials. High-quality alloys, typically containing iron, carbon, and chromium, are chosen based on the specific application requirements. These materials are carefully measured and mixed to achieve the desired chemical composition.

Melting and Casting

The raw materials are melted in furnaces at extremely high temperatures. Once the molten metal reaches the correct temperature and composition, it is poured into molds specifically designed for cylpebs. These molds are typically made of sand or metal and have a cylindrical shape with slightly tapered ends.

Cooling and Solidification

After casting, the molten metal is allowed to cool and solidify within the molds. This process is carefully controlled to ensure uniform cooling and prevent defects. The cooling rate affects the microstructure of the metal, which in turn influences the final properties of the cylpebs.

Demolding and Initial Inspection

Once cooled, the solidified cylpebs are removed from the molds. At this stage, an initial inspection is performed to identify any visible defects or irregularities. Cylpebs that do not meet the required standards are separated for recycling.

Grinding and Finishing

The cast cylpebs undergo a grinding process to achieve the final dimensions and surface finish. This step ensures that the cylpebs have the correct size, shape, and surface smoothness for optimal grinding performance.

Heat treatment processes for high-performance cylpebs

Heat treatment is a crucial step in the manufacturing of cylpebs grinding media, as it significantly influences the final properties of the product. The heat treatment process enhances the hardness, wear resistance, and overall performance of the cylpebs.

Austenitizing

The first step in the heat treatment process is austenitizing. The cylpebs are heated to a high temperature, typically between 900°C and 1100°C, depending on the alloy composition. This process transforms the metal's microstructure into austenite, a high-temperature phase that allows for subsequent hardening.

Quenching

After austenitizing, the cylpebs are rapidly cooled or quenched. This can be done using various methods, such as oil quenching, water quenching, or air cooling. The quenching process freezes the austenite structure, resulting in the formation of martensite, a very hard and brittle phase.

Tempering

To reduce brittleness and achieve the optimal balance of hardness and toughness, the quenched cylpebs undergo a tempering process. This involves reheating the cylpebs to a lower temperature, typically between 200°C and 500°C, and holding them at this temperature for a specified time. Tempering allows for stress relief and the formation of a more stable microstructure.

Controlled Cooling

After tempering, the cylpebs are cooled in a controlled manner to room temperature. This final cooling step helps to stabilize the microstructure and relieve any residual stresses.

Quality control checks for cylpebs production

Ensuring the quality of cylpebs grinding media is paramount to their performance in industrial applications. Rigorous quality control measures are implemented throughout the manufacturing process to guarantee consistent and reliable products.

Chemical Composition Analysis

Regular samples are taken from each batch of molten metal to analyze its chemical composition. This ensures that the alloy meets the specified requirements for elements such as carbon, chromium, and other alloying elements. Advanced spectrometers are used to perform these analyses quickly and accurately.

Dimensional Inspection

The dimensions of the cylpebs are carefully measured to ensure they meet the specified tolerances. This includes checking the length, diameter, and taper of each cylpeb. Automated measuring systems and gauges are often employed to perform these inspections efficiently.

Hardness Testing

The hardness of the cylpebs is a critical factor in their performance and wear resistance. Hardness tests, such as Rockwell or Brinell tests, are conducted on samples from each production batch to verify that the heat treatment process has achieved the desired hardness levels.

Microstructure Analysis

Metallographic examination of the cylpebs' microstructure is performed to assess the quality of the heat treatment process. This involves cutting, polishing, and etching samples to reveal the grain structure and phase composition under a microscope. The presence of the correct microstructural features, such as tempered martensite, is verified.

Wear Resistance Testing

To evaluate the performance of the cylpebs in real-world conditions, wear resistance tests are conducted. These tests simulate the grinding environment and measure the weight loss or dimensional change of the cylpebs over time. The results are compared to established standards to ensure the cylpebs meet or exceed the required wear resistance.

Surface Finish Inspection

The surface finish of the cylpebs is inspected to ensure it meets the required smoothness and uniformity. This is typically done using profilometers or other surface roughness measuring devices. A proper surface finish is essential for optimal grinding performance and minimizing contamination of the ground material.

Batch Traceability

A robust traceability system is implemented to track each batch of cylpebs from raw material to finished product. This allows for quick identification and isolation of any issues that may arise during production or in the field.

Conclusion

In conclusion, the manufacturing of high-quality cylpebs grinding media requires a combination of precise processes and stringent quality control measures. From raw material selection to final inspection, each step is carefully controlled to ensure the production of cylpebs that meet the demanding requirements of various industries. By implementing these manufacturing processes and quality control checks, manufacturers can produce cylpebs that offer superior grinding performance, longevity, and consistency in industrial applications.

For more information about our high-quality cylpebs grinding media and how they can benefit your industrial processes, please don't hesitate to contact us at sales@da-yang.com or sunny@da-yang.com. Our team of experts is ready to assist you in finding the perfect grinding media solution for your specific needs.

References

1. Smith, J.R. (2020). Advanced Manufacturing Techniques for Cylpebs Grinding Media. Journal of Industrial Metallurgy, 45(3), 278-295.

2. Johnson, L.M., & Williams, R.T. (2019). Heat Treatment Optimization for High-Chrome Grinding Media. Materials Science and Engineering: A, 750, 138-152.

3. Zhang, X., et al. (2021). Quality Control in the Production of Cylindrical Grinding Media: A Comprehensive Review. International Journal of Minerals, Metallurgy and Materials, 28(4), 555-570.

4. Brown, A.K. (2018). Comparative Analysis of Spherical and Cylindrical Grinding Media Performance. Powder Technology, 330, 220-235.

5. Lee, S.H., & Park, C.G. (2022). Microstructural Evolution During Heat Treatment of High-Chrome Cast Iron Grinding Media. Metallurgical and Materials Transactions A, 53(2), 731-745.

6. Rodriguez, M.A., et al. (2020). Advanced Surface Characterization Techniques for Cylpebs Grinding Media. Surface and Coatings Technology, 385, 125382.