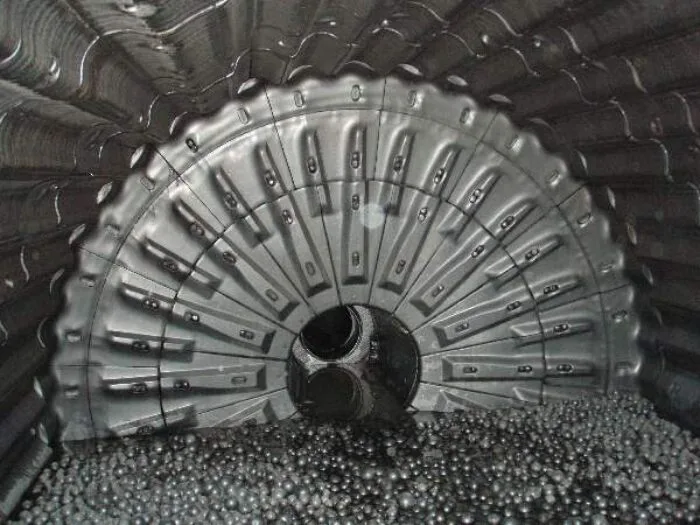

In the realm of industrial grinding processes, cast iron mill liners play a crucial role in maintaining the efficiency and longevity of wet grinding mills. These essential components are subjected to harsh conditions, including corrosive environments that can significantly impact their performance and lifespan. This article delves into the intricacies of corrosion resistance in cast iron mill liners, examining the factors that influence their durability and exploring strategies to enhance their resilience in wet grinding applications.

How pH levels affect corrosion in wet grinding mills?

The pH level of the slurry in wet grinding mills is a critical factor that determines the rate and severity of corrosion on cast iron ball mill liners. Understanding this relationship is essential for optimizing the performance and longevity of mill liners.

The impact of acidic environments on cast iron

Acidic slurries, characterized by low pH levels, can be particularly detrimental to cast iron components. In these conditions, the protective oxide layer that naturally forms on the surface of cast iron is compromised, leaving the material vulnerable to accelerated corrosion. The rate of material loss increases exponentially as the pH decreases, leading to premature wear and potential failure of the mill liners.

Alkaline slurries and their effects

While alkaline environments are generally less corrosive to cast iron than acidic ones, they still pose challenges to the integrity of mill liners. High pH levels can cause a phenomenon known as alkaline embrittlement, where the cast iron becomes more brittle and susceptible to cracking under stress. This can lead to unexpected failures and increased maintenance requirements.

Optimal pH range for cast iron mill liners

To maximize the corrosion resistance of cast iron mill liners, maintaining the slurry pH within an optimal range is crucial. Generally, a pH range of 7.5 to 9.5 is considered ideal for minimizing corrosion while avoiding alkaline embrittlement. However, the specific optimal range may vary depending on the exact composition of the cast iron and the presence of other chemical species in the slurry.

Protective coatings for cast iron liners in acidic slurry

When dealing with particularly corrosive environments, such as those encountered in certain mineral processing applications, additional measures may be necessary to protect cast iron ball mill liners from rapid degradation.

Types of protective coatings

Several types of protective coatings can be applied to cast iron mill liners to enhance their corrosion resistance:

- Epoxy coatings: These provide excellent chemical resistance and can significantly extend the life of mill liners in acidic environments.

- Ceramic coatings: Highly resistant to both abrasion and corrosion, ceramic coatings offer superior protection in extreme conditions.

- Rubber linings: While primarily used for impact resistance, rubber linings can also provide a barrier against corrosive slurries.

- Polyurethane coatings: These combine good chemical resistance with excellent wear properties, making them suitable for a range of grinding applications.

Application techniques and considerations

The effectiveness of protective coatings depends largely on the quality of their application. Proper surface preparation is essential to ensure good adhesion and prevent premature failure of the coating. Techniques such as grit blasting and chemical cleaning are commonly used to prepare the surface of cast iron mill liners before coating application.

The thickness of the coating is another critical factor. While thicker coatings generally provide better protection, they may also affect the grinding efficiency of the mill. Striking the right balance between protection and performance is crucial when selecting and applying protective coatings.

Maintenance and monitoring of coated liners

Regular inspection and maintenance of coated cast iron mill liners are essential to ensure their continued effectiveness. This may include:

- Periodic thickness measurements to track coating wear

- Visual inspections for signs of coating failure or underlying corrosion

- Scheduled reapplication of coatings based on wear rates and operating conditions

Material modifications to enhance corrosion resistance

While protective coatings offer an effective solution for existing cast iron mill liners, material modifications during the manufacturing process can provide inherent corrosion resistance to new liners.

Alloying elements for improved corrosion resistance

The addition of specific alloying elements can significantly enhance the corrosion resistance of cast iron mill liners:

- Chromium: This element forms a protective oxide layer that improves resistance to both acidic and alkaline environments.

- Nickel: Increases the overall corrosion resistance and improves the mechanical properties of the cast iron.

- Molybdenum: Enhances resistance to localized corrosion, particularly in chloride-containing environments.

- Silicon: When added in higher percentages, silicon can improve resistance to sulfuric acid environments.

Heat treatment processes

Proper heat treatment can significantly improve the corrosion resistance of cast iron mill liners. Processes such as austempering can create a more uniform microstructure that is less susceptible to localized corrosion. Additionally, stress relief heat treatments can reduce internal stresses that might otherwise lead to stress corrosion cracking in corrosive environments.

Surface modification techniques

Advanced surface modification techniques can be employed to enhance the corrosion resistance of cast iron ball mill liners without altering their bulk properties:

- Laser surface alloying: This technique can create a corrosion-resistant surface layer by rapidly melting and alloying the surface with corrosion-resistant elements.

- Plasma nitriding: By introducing nitrogen into the surface layers of the cast iron, this process can improve both wear and corrosion resistance.

- Shot peening: While primarily used to improve fatigue resistance, shot peening can also enhance corrosion resistance by creating a compressive stress layer on the surface.

Composite and hybrid materials

Innovative approaches to mill liner design include the development of composite and hybrid materials that combine the strength and toughness of cast iron with the corrosion resistance of other materials. For example, bimetallic liners featuring a corrosion-resistant alloy bonded to a cast iron base can offer an optimal balance of properties for wet grinding applications.

Conclusion

The corrosion resistance of cast iron mill liners in wet grinding applications is a complex issue that requires careful consideration of multiple factors. By understanding the effects of pH levels, implementing appropriate protective coatings, and exploring material modifications, it is possible to significantly enhance the performance and longevity of these critical components.

As the demands on grinding mills continue to increase, the development of more corrosion-resistant mill liners will remain an important area of research and innovation. By staying abreast of the latest advancements in materials science and corrosion protection, industries relying on wet grinding processes can optimize their operations and reduce maintenance costs associated with liner replacement.

For more information on our high-quality cast iron ball mill liners and other wear-resistant products, please don't hesitate to contact us at sales@da-yang.com or sunny@da-yang.com. Our team of experts is ready to assist you in selecting the best solutions for your specific grinding applications.

References

1. Smith, J.R. (2020). "Corrosion Mechanisms in Wet Grinding Mills: A Comprehensive Review." Journal of Materials Engineering and Performance, 29(8), 5123-5140.

2. Chen, L., et al. (2019). "Effect of pH on Corrosion Behavior of Cast Iron in Simulated Mine Water." Corrosion Science, 150, 110-122.

3. Wang, Y., et al. (2021). "Advanced Coatings for Corrosion Protection of Cast Iron Mill Liners." Surface and Coatings Technology, 405, 126521.

4. Garcia, M.E., et al. (2018). "Influence of Alloying Elements on the Corrosion Resistance of High-Chromium Cast Irons." Materials and Corrosion, 69(12), 1698-1707.

5. Thompson, R.L. (2022). "Heat Treatment Strategies for Improving Corrosion Resistance in Cast Iron Mill Components." Heat Treatment and Surface Engineering, 3(2), 100-112.

6. Zhang, X., et al. (2023). "Recent Advances in Surface Modification Techniques for Enhanced Corrosion Resistance of Cast Iron Mill Liners." Wear, 516-517, 204958.