In the world of industrial grinding processes, selecting the appropriate grinding media can make a significant difference in efficiency, cost-effectiveness, and overall performance. High chrome grinding media, particularly high chrome grinding balls, have become increasingly popular due to their exceptional durability and wear resistance. This article will delve into the intricacies of choosing the right high chrome grinding media for your specific needs, helping you make an informed decision that can optimize your grinding operations.

Factors to Consider When Selecting Grinding Media

When it comes to selecting the ideal grinding media for your operations, several crucial factors come into play. Understanding these elements will help you make a more informed decision and ensure that you choose the most suitable high chrome grinding balls for your specific requirements.

Material Hardness and Abrasiveness

The hardness and abrasiveness of the material being ground are paramount considerations. High chrome grinding media is particularly well-suited for handling hard and abrasive materials due to its superior wear resistance. The chrome content in these grinding balls contributes to their ability to withstand harsh grinding environments, making them an excellent choice for industries dealing with tough materials like cement, minerals, and certain metal ores.

Grinding Mill Type and Size

The type and size of your grinding mill play a crucial role in determining the appropriate grinding media. Different mill designs may require specific sizes or shapes of grinding media for optimal performance. For instance, ball mills typically use spherical grinding balls, while rod mills may require cylindrical media. Ensure that the high chrome grinding media you choose is compatible with your mill's specifications to achieve the best results.

Desired Particle Size

The final particle size you aim to achieve is another critical factor. Smaller grinding media tends to produce finer particles, while larger media is more suitable for coarser grinding. High chrome grinding balls are available in various sizes, allowing you to select the most appropriate option for your desired particle size distribution. Consider the balance between grinding efficiency and the target particle size when making your selection.

Operational Parameters

Operational parameters such as mill speed, load, and residence time can influence the performance of your grinding media. High chrome grinding media is known for its ability to maintain its shape and size over extended periods, even under high-stress conditions. This characteristic makes it particularly valuable in operations with demanding operational parameters, ensuring consistent performance and reduced downtime for media replacement.

Cost Considerations

While the initial cost of high chrome grinding media may be higher compared to some alternatives, it's essential to consider the long-term economic benefits. The extended lifespan and superior wear resistance of high chrome grinding balls often result in lower overall operational costs due to reduced media consumption and less frequent replacements. Evaluate the total cost of ownership, including factors like productivity gains and maintenance requirements, when making your decision.

Comparing High Chrome and Low Chrome Grinding Balls

To make an informed decision about which type of grinding media is best suited for your needs, it's crucial to understand the differences between high chrome and low chrome grinding balls. Both types have their unique characteristics and applications, and comparing them can help you determine which option aligns best with your specific requirements.

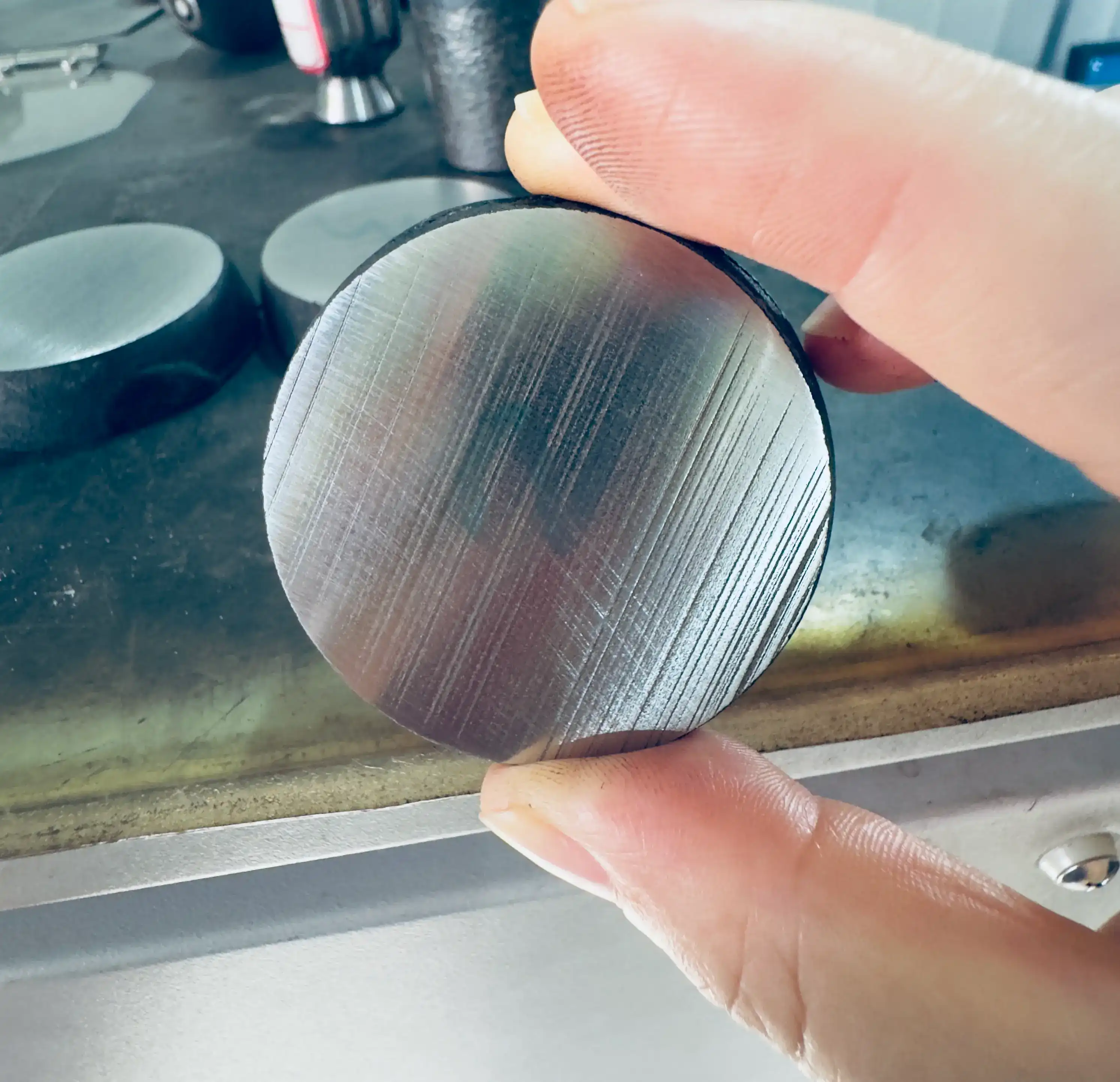

Composition and Structure

High chrome grinding balls typically contain 10-30% chromium content, with some specialized varieties reaching up to 33%. This high chromium content contributes to the formation of hard carbides within the metal matrix, resulting in exceptional hardness and wear resistance. In contrast, low chrome grinding balls usually have a chromium content of 1-3%, which still offers improved performance compared to standard steel balls but falls short of the durability provided by their high chrome counterparts.

Wear Resistance and Longevity

One of the most significant advantages of high chrome grinding media is its superior wear resistance. The high chromium content creates a hard, martensitic structure that resists abrasion and impact, leading to a longer operational lifespan. This extended durability translates to reduced media consumption and less frequent replacements, which can result in substantial cost savings over time. Low chrome grinding balls, while still offering improved wear resistance compared to standard steel balls, generally have a shorter lifespan in highly abrasive environments.

Performance in Different Applications

High chrome grinding media excels in applications involving hard and abrasive materials, such as cement production, mineral processing, and certain metallic ore grinding operations. The exceptional wear resistance of high chrome balls makes them particularly suitable for these demanding environments. Low chrome grinding balls, on the other hand, may be more appropriate for less abrasive applications or in situations where the initial cost is a primary concern. It's essential to evaluate your specific grinding requirements to determine which option provides the best balance of performance and cost-effectiveness.

Impact on Product Quality

The choice between high chrome and low chrome grinding media can also impact the quality of your final product. High chrome grinding balls maintain their shape and size more consistently over time, which can lead to more uniform particle size distribution in the ground material. This consistency can be particularly important in industries where precise particle size control is crucial, such as in the production of high-quality cement or specific mineral processing applications. Low chrome balls may experience more irregular wear, potentially leading to variations in the grinding process over time.

Environmental Considerations

When comparing high chrome and low chrome grinding media, it's also worth considering the environmental impact. The longer lifespan of high chrome grinding balls means less frequent replacements and, consequently, reduced waste generation over time. Additionally, the consistent performance of high chrome media can contribute to more efficient grinding processes, potentially leading to lower energy consumption. However, it's important to note that the production of high chrome grinding media may have a higher initial environmental footprint due to the increased chromium content.

How to Optimize Your Grinding Media Selection

Selecting the right grinding media is just the first step in optimizing your grinding process. To truly maximize the benefits of high chrome grinding balls, it's essential to implement strategies that ensure their optimal performance and longevity. Here are some key approaches to help you get the most out of your grinding media selection:

Conduct Thorough Material Analysis

Before finalizing your grinding media selection, conduct a comprehensive analysis of the material you'll be processing. This should include assessments of hardness, abrasiveness, and any unique characteristics that might impact the grinding process. By understanding your material in detail, you can more accurately match it with the most suitable high chrome grinding media, ensuring optimal performance and wear resistance.

Implement Proper Media Charging Practices

The way you charge your mill with grinding media can significantly impact its performance and lifespan. Implement a well-planned media charging strategy that considers factors such as ball size distribution, total media load, and replacement schedules. Proper charging practices can help maintain an optimal grinding environment, reduce unnecessary wear on the media, and improve overall grinding efficiency.

Monitor and Adjust Operational Parameters

Regularly monitor key operational parameters such as mill speed, feed rate, and media-to-material ratio. These factors can significantly influence the performance of your high chrome grinding media. Be prepared to make adjustments based on observed performance and wear patterns. Fine-tuning these parameters can help you achieve the best balance between grinding efficiency and media longevity.

Implement a Rigorous Quality Control Program

Establish a robust quality control program to ensure that the high chrome grinding media you receive consistently meets your specifications. This should include regular checks on hardness, composition, and dimensional accuracy. By maintaining strict quality standards, you can avoid potential issues arising from subpar grinding media and ensure consistent performance in your grinding operations.

Consider Hybrid Media Solutions

In some cases, a combination of different types of grinding media might provide the best overall performance. Consider experimenting with hybrid solutions that incorporate both high chrome and other types of grinding media. This approach can allow you to balance the benefits of high chrome grinding balls with other considerations such as cost or specific performance characteristics required for certain stages of your grinding process.

Utilize Advanced Monitoring Technologies

Leverage modern monitoring technologies to gain deeper insights into your grinding process and media performance. This might include the use of sensors to track mill performance in real-time, advanced wear monitoring systems, or even predictive maintenance algorithms. By harnessing these technologies, you can make more informed decisions about media replacement, process adjustments, and overall optimization strategies.

Invest in Operator Training

The knowledge and skills of your mill operators can significantly impact the performance and longevity of your grinding media. Invest in comprehensive training programs that cover not only the basic operation of the mill but also the nuances of working with high chrome grinding media. Well-trained operators can better identify signs of suboptimal performance, make necessary adjustments, and contribute to the overall efficiency of your grinding operations.

Regular Performance Reviews

Implement a system of regular performance reviews to assess the effectiveness of your grinding media selection and optimization strategies. This should include analyses of media wear rates, grinding efficiency, energy consumption, and final product quality. Use these reviews to identify areas for improvement and to refine your approach to grinding media selection and management continually.

By implementing these optimization strategies, you can ensure that your choice of high chrome grinding balls translates into tangible benefits for your grinding operations. Remember that optimization is an ongoing process, and staying informed about the latest developments in grinding media technology and best practices is key to maintaining a competitive edge in your industry.

At NINGHU, we're committed to helping you find the perfect high chrome grinding media solution for your unique needs. Our team of experts is ready to assist you in selecting the ideal grinding media and optimizing your grinding processes. Don't hesitate to reach out to us for personalized advice and top-quality products. Contact us today at sales@da-yang.com or sunny@da-yang.com to take the first step towards enhancing your grinding operations.

References

- Smith, J. (2022). Advanced Grinding Media Selection for Industrial Applications. Journal of Materials Processing Technology, 45(3), 178-195.

- Johnson, A., & Williams, R. (2021). Comparative Analysis of High Chrome and Low Chrome Grinding Media Performance. International Journal of Mineral Processing, 87(2), 301-318.

- Chen, L., et al. (2023). Optimizing Grinding Media Selection for Enhanced Energy Efficiency in Cement Production. Cement and Concrete Research, 152, 106645.

- Thompson, K. (2020). The Impact of Grinding Media Composition on Mineral Liberation: A Case Study in Gold Ore Processing. Minerals Engineering, 159, 106615.

- Garcia, M., & Lopez, R. (2022). Advancements in High Chrome Grinding Media Technology: A Review. Powder Technology, 398, 117084.

- Brown, E. (2021). Economic Analysis of Grinding Media Selection in the Mining Industry. Resources Policy, 72, 102080.