Sorting and grading worn media

The first step in recycling grinding media is to properly sort and grade the worn media. This process is essential to determine which media can be reused and which need to be replaced.

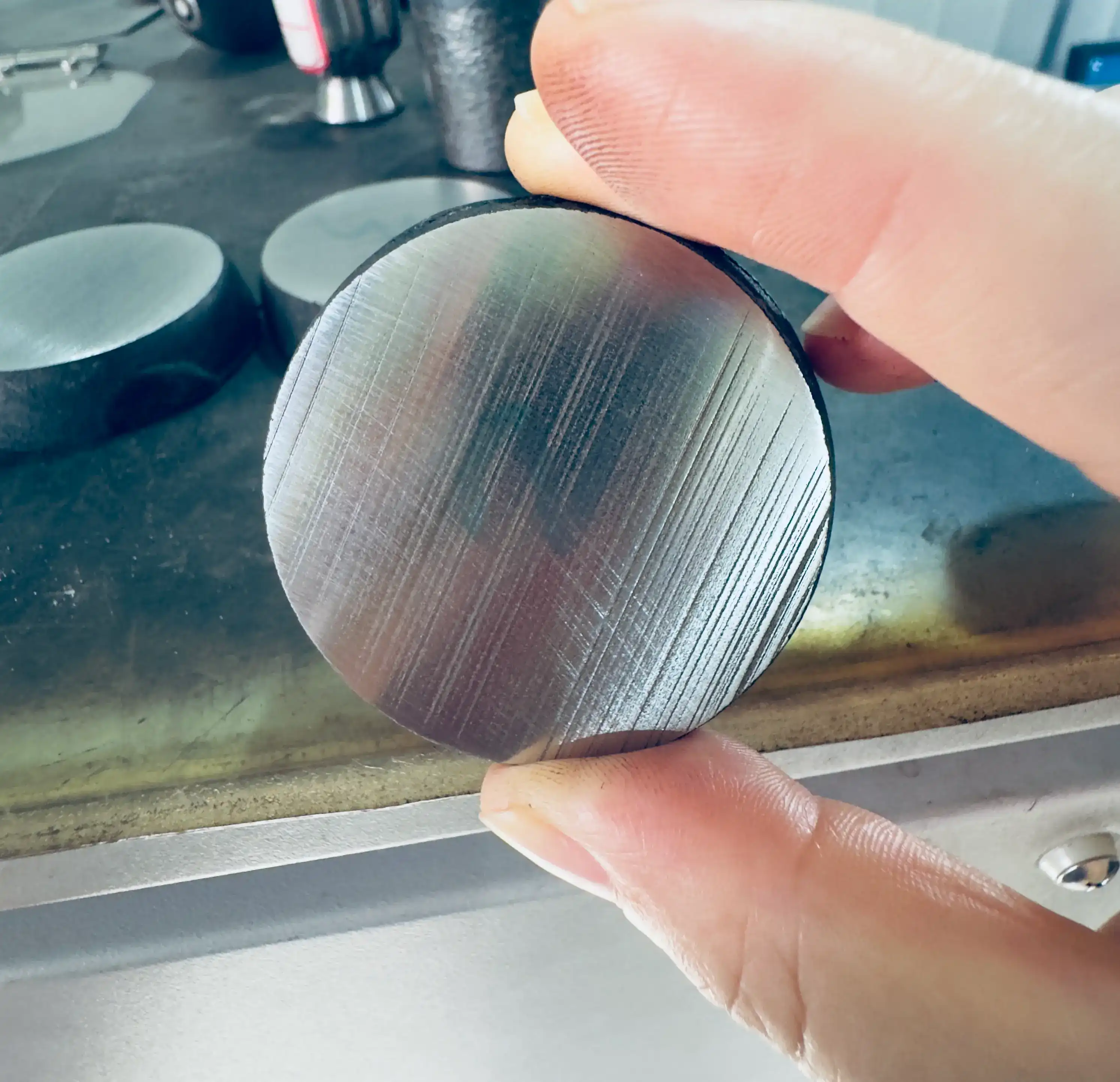

Visual inspection and size measurement

One of the primary methods of sorting worn grinding media is through visual inspection. Experienced operators can often identify media that have become too small or misshapen for effective use. Additionally, size measurement tools can be employed to accurately assess the dimensions of used media.

Automated sorting systems

For larger operations, automated sorting systems can be implemented to streamline the process. These systems use advanced technologies such as machine vision and artificial intelligence to quickly and accurately sort grinding media based on size, shape, and condition.

Wear rate analysis

Understanding the wear rate of the product is crucial for effective recycling. By analyzing the wear patterns and rates of different media types, operators can better predict when media will need to be replaced and optimize their recycling efforts.

Economic benefits of media recycling

Recycling grinding media can offer significant economic advantages for ball milling operations. By extending the lifespan of media and reducing the need for frequent replacements, companies can realize substantial cost savings.

Reduced material costs

One of the most apparent economic benefits of recycling grinding media is the reduction in material costs. By reusing media that still have useful life, companies can decrease their expenditure on new product. This can be particularly impactful for operations that use large volumes of media or expensive materials such as high chrome grinding media.

Improved operational efficiency

Recycling grinding media can also lead to improved operational efficiency. By maintaining a consistent size distribution of media within the mill, operators can optimize grinding performance and energy consumption. This can result in higher throughput and lower energy costs per unit of material processed.

Decreased waste management costs

The amount of garbage that has to be disposed of is drastically decreased when products are recycled. Transportation and disposal prices associated with waste management may be reduced as a result. Further improving the economic advantages, certain localities may even provide incentives or tax benefits to enterprises who adopt recycling systems.

Implementing a sustainable media management system

To fully realize the benefits of recycling grinding media, it's essential to implement a comprehensive and sustainable media management system.

Regular media audits

Conducting regular audits of the product is crucial for effective recycling. These audits should assess the condition of media, track wear rates, and identify opportunities for optimization. By maintaining detailed records, operators can make informed decisions about when to recycle or replace media.

Employee training and engagement

Successful implementation of a media recycling program requires the involvement and commitment of all employees involved in the ball milling process. Providing comprehensive training on sorting techniques, recycling procedures, and the importance of sustainability can help ensure the program's success.

Collaboration with suppliers

Working closely with grinding media suppliers can be beneficial in developing effective recycling strategies. Some suppliers may offer take-back programs for worn media or provide guidance on optimal recycling practices. Establishing strong partnerships can lead to more sustainable and cost-effective media management.

Integration with overall sustainability initiatives

Recycling this product should be integrated into a company's broader sustainability initiatives. This can include setting targets for media recycling rates, reporting on the environmental impact of recycling efforts, and continually seeking ways to improve the sustainability of ball milling operations.

Challenges and considerations in grinding media recycling

While recycling grinding media offers numerous benefits, there are also challenges and considerations that need to be addressed for successful implementation.

Quality control

Maintaining consistent quality in recycled grinding media is crucial for optimal mill performance. Rigorous quality control measures must be in place to ensure that recycled media meet the necessary specifications for size, shape, and material properties.

Contamination risks

In some applications, particularly in industries with strict purity requirements, there may be concerns about potential contamination from recycled media. It's essential to carefully evaluate these risks and implement appropriate measures to mitigate them, such as thorough cleaning processes or limiting recycling to certain applications.

Equipment and infrastructure requirements

Implementing a comprehensive grinding media recycling program may require investments in equipment and infrastructure. This can include sorting systems, storage facilities, and possibly modifications to existing mill designs to accommodate recycled media more effectively.

Case studies: Successful grinding media recycling programs

Examining real-world examples of successful grinding media recycling programs can provide valuable insights and inspiration for companies looking to implement their own initiatives.

Mining industry example

A large copper mine implemented a grinding media recycling program that focused on sorting and reusing high chrome grinding balls. By carefully grading worn media and reintroducing suitable balls back into the mill, the company was able to reduce its annual media consumption by 15% and achieve significant cost savings.

Cement production case study

A cement manufacturer developed a comprehensive media management system that included regular audits, automated sorting, and collaboration with suppliers. The program resulted in a 20% reduction in new media purchases and improved overall mill efficiency by maintaining more consistent media size distribution.

Conclusion

The potential for substantial monetary and ecological gains from recycling grinding media in ball milling processes is substantial. Companies may reduce costs and environmental impact while extending the lifetime of their products via the implementation of complete media management systems, efficient sorting and grading procedures, and taking use of economic benefits.

Problems including quality control, contamination hazards, and infrastructure needs must be carefully considered for implementation to be a success. With the constant advancement of technology and the growing importance of sustainability, the product recycling industry is poised for an exciting future filled with possibilities for new innovations and efficiency gains.

The capacity to recycle this product offers a significant chance for enterprises to improve their bottom line while simultaneously making their ball milling processes more sustainable.

Call to Action

Would you want to learn more about grinding media recycling and how it might help your ball milling operations run more smoothly? Grinding balls and cylpebs made of high-chrome steel, among other products offered by NINGHU, are known for their long lifespans and outstanding performance. A long-term plan for managing your media assets may be crafted with the assistance of our professional staff.

Contact us today to learn more about our products and how we can support your product recycling efforts. Reach out to our sales team at sales@da-yang.com or sunny@da-yang.com to discuss your requirements and discover how NINGHU can help you achieve more efficient and sustainable ball milling operations.

References

1. Johnson, R. M., & Smith, K. L. (2019). Sustainable practices in mineral processing: A review of grinding media recycling techniques. Journal of Cleaner Production, 178, 45-59.

2. Zhang, Y., & Wang, H. (2020). Optimization of grinding media recycling in cement production: A case study. Cement and Concrete Research, 130, 105988.

3. López-Saucedo, F., et al. (2021). Economic and environmental impact assessment of grinding media recycling in mining operations. Resources, Conservation and Recycling, 164, 105142.

4. Anderson, M. J., & Thompson, R. C. (2018). Advanced sorting technologies for grinding media recycling: A comparative analysis. Minerals Engineering, 121, 90-102.

5. Patel, S., & Gupta, A. K. (2022). Circular economy approaches in ball mill operations: Challenges and opportunities. Journal of Industrial Ecology, 26(3), 789-803.

6. Fernández-González, D., et al. (2020). Life cycle assessment of grinding media recycling in the mining industry: A sustainability perspective. Journal of Cleaner Production, 256, 120385.