Pros and cons of mixed media milling

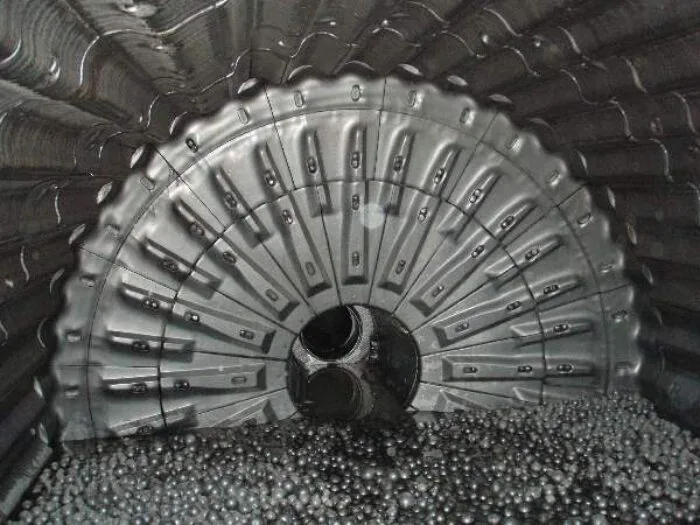

Mixed media milling, the practice of combining different types of ball mill media in a single mill, has garnered attention for its potential to enhance grinding efficiency. Let's examine the advantages and disadvantages of this approach.

Advantages of mixed media milling

- Improved grinding efficiency: By combining media of different sizes and materials, mixed media milling can potentially cover a wider range of particle sizes, leading to more efficient grinding.

- Enhanced particle size distribution: The variety in media types can contribute to a more uniform particle size distribution in the final product.

- Reduced wear on mill components: Strategic media combinations can help distribute the grinding load more evenly, potentially reducing wear on mill liners and other components.

- Flexibility in grinding parameters: Mixed media allows for greater flexibility in adjusting grinding parameters to suit different materials or desired outcomes.

Disadvantages of mixed media milling

- Increased complexity: Managing multiple media types adds complexity to the milling process and may require more sophisticated monitoring and control systems.

- Potential for media segregation: Different media types may segregate within the mill due to variations in size, density, or shape, potentially reducing grinding efficiency.

- Higher initial costs: Procuring and maintaining multiple media types can increase operational costs.

- Risk of contamination: When mixing media of different materials, there's a potential risk of cross-contamination, which could be problematic in industries with strict purity requirements.

Optimal ratios for combining different media types

Determining the optimal ratio for mixing different ball mill media types is a complex process that depends on various factors, including the material being ground, desired particle size, and mill specifications. However, some general guidelines can help in achieving effective mixed media milling.

Factors influencing optimal media ratios

- Material characteristics: The hardness, brittleness, and initial particle size of the material being ground significantly influence the ideal media mix.

- Desired particle size: The target particle size distribution affects the choice of media sizes and their proportions in the mix.

- Mill type and specifications: Different mill designs may require different media mixes for optimal performance.

- Grinding environment: Wet or dry grinding conditions can impact the effectiveness of different media combinations.

Common mixed media combinations

While the specific ratios will vary based on the factors mentioned above, some common mixed media combinations include:

- Large and small media of the same material: For example, mixing 30% large steel balls with 70% smaller steel balls to handle a wide range of particle sizes.

- Different materials: Combining 60% high-density ceramic balls with 40% steel balls to balance wear resistance and grinding impact.

- Graduated size distribution: Using a mix of ball sizes in a ratio of 1:2:3 (small:medium:large) to optimize grinding efficiency across different particle size ranges.

It's important to note that these ratios are general examples and should be fine-tuned based on specific grinding requirements and empirical testing.

Performance analysis of mixed vs. uniform media

To truly understand the benefits and limitations of mixed media milling, it's essential to compare its performance against traditional uniform ball mill media. This comparison can provide valuable insights for industries considering a shift to mixed media approaches.

Grinding efficiency

Studies have shown that in certain applications, mixed media milling can achieve higher grinding efficiency compared to uniform media. This is particularly true when dealing with materials that have a wide initial particle size distribution. The combination of different media sizes and materials can more effectively target various particle sizes simultaneously, potentially reducing grinding time and energy consumption.

Product quality

The impact of mixed media on product quality can vary depending on the specific application. In some cases, mixed media milling has been found to produce a more uniform particle size distribution, which can be beneficial in industries where particle size consistency is crucial. However, in applications where product purity is paramount, the potential for contamination from multiple media types must be carefully considered.

Wear rates and operational costs

The wear rates of mixed media can differ significantly from uniform media. While some combinations may lead to reduced overall wear by distributing the grinding load more evenly, others might result in accelerated wear of certain media types. This variability underscores the importance of careful media selection and ratio optimization to balance performance and operational costs.

Process control and consistency

Maintaining consistent process control can be more challenging with mixed media due to the potential for media segregation and the need to manage multiple variables. However, when properly implemented, mixed media milling can offer greater flexibility in adjusting grinding parameters to meet changing product requirements.

In conclusion, while mixed media milling shows promise in enhancing grinding efficiency and product quality in certain applications, its implementation requires careful consideration of material properties, desired outcomes, and operational constraints. Empirical testing and optimization are essential to determine whether mixed media milling offers significant advantages over uniform media for a specific grinding process.

FAQ

1. What are the most common types of media used in mixed media milling?

The most common types of media used in mixed media milling include steel balls of varying sizes, ceramic balls (such as alumina or zirconia), and in some cases, cylpebs or rods. The choice depends on the specific grinding requirements and material properties.

2. How does mixed media milling affect the energy consumption of the milling process?

Mixed media milling can potentially reduce energy consumption by improving grinding efficiency. However, the actual impact on energy consumption varies depending on the specific media combination, material being ground, and mill operating conditions.

3. Are there any industries where mixed media milling is particularly beneficial?

Mixed media milling has shown particular benefits in industries dealing with materials that have a wide particle size distribution, such as certain mining operations, cement production, and some sectors of the chemical industry. However, its applicability should be evaluated on a case-by-case basis.

Contact NINGHU for Expert Grinding Media Solutions

NINGHU, a recognised ball mill media manufacturer, can provide the knowledge in high-quality ball mill media that helps you obtain better outcomes whether you're thinking about using mixed media milling or want to optimise your present grinding operations. When it comes to grinding, our expert staff can help you choose the right media mix for your needs, so you get the best possible results.

To learn more about our range of grinding media options and how we can support your milling needs, please don't hesitate to reach out to us at sales@da-yang.com or sunny@da-yang.com. Let NINGHU be your partner in advancing your grinding technology and achieving your production goals.